Coated welding wire for welding low-alloy high-strength steel and manufacturing method

A high-strength steel and low-alloy technology, applied in the field of coated welding wire and preparation for low-alloy high-strength steel welding, can solve the problems of industrial production loss, affecting the mechanical properties of welding products, and the strength of low-alloy steel, so as to reduce cold cracks and Effect of diffusible hydrogen content, enhanced weld strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

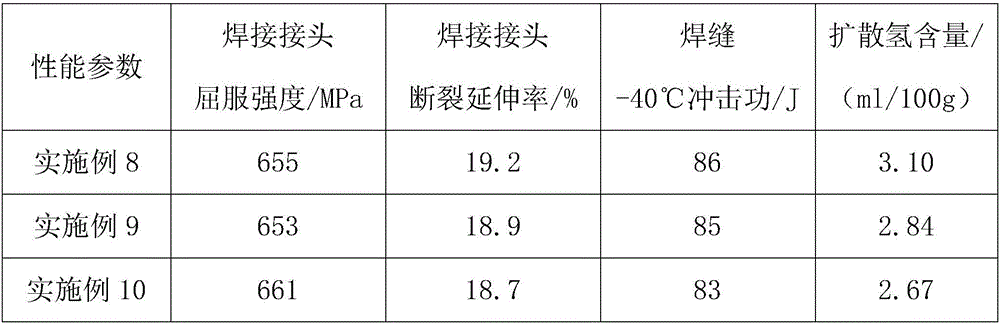

Examples

Embodiment 1

[0055] A coated welding wire for low-alloy high-strength steel welding, including a welding wire base and a coating on the surface of the welding wire base, wherein the welding wire base components include: Ti 0.029%, Al 0.01%, Nb 0.11%, C 0.1% , Cr0.2%, Si 0.3%, N 0.03%, Ni 4%, Mo 0.1%, P≤0.002%, S≤0.002%, the balance is iron and unavoidable impurities; among them, K specified by the following formula with a value of 0.013,

[0056] K=29[Ti]+52[Al]+27[Nb]-100[N],

[0057] Where [Al], [Ti], [Nb] and [N] represent the weight percentages of Al, Ti, Nb and N in the wire matrix components, respectively.

Embodiment 2

[0059] A coated welding wire for low-alloy high-strength steel welding, including a welding wire base and a coating on the surface of the welding wire base, wherein the welding wire base components include: Ti 0.041%, Al 0.015%, Nb 0.083%, C 0.15% , Cr0.3%, Si 0.5%, N 0.01%, Ni 7%, Mo 0.6%, P≤0.002%, S≤0.002%, the balance is iron and unavoidable impurities; among them, K specified by the following formula with a value of 0.032,

[0060] K=29[Ti]+52[Al]+27[Nb]-100[N],

[0061] Where [Al], [Ti], [Nb] and [N] represent the weight percentages of Al, Ti, Nb and N in the wire matrix components, respectively.

Embodiment 3

[0063] A coated welding wire for low-alloy high-strength steel welding, including a welding wire base and a coating on the surface of the welding wire base, wherein the welding wire base components include: Ti 0.032%, Al 0.013%, Nb 0.095%, C 0.12% , Cr0.25%, Si 0.4%, N 0.02%, Ni 5.5%, Mo 0.35%, P≤0.002%, S≤0.002%, the balance is iron and unavoidable impurities; surface coating raw materials include by weight percentage : 5% of graphite, 15% of lithium carbonate, 7% of potassium carbonate, 10% of sodium carbonate, 7% of titanium dioxide, 4% of feldspar, 44% of deoxidizer, and 8% of active agent; wherein, the K value specified by the following formula 0.022,

[0064] K=29[Ti]+52[Al]+27[Nb]-100[N],

[0065] Where [Al], [Ti], [Nb] and [N] represent the weight percentages of Al, Ti, Nb and N in the wire matrix components, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com