Welding method for preventing generation of granular ferrite in SA335-T/P92 steel weld heat affected zone

A SA335-T, bulk ferrite technology, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve the problem that P91 cannot meet the requirements of long-term safe operation, hidden dangers of safe operation of power stations, and long cycle and other problems, to achieve the effect of reducing stress corrosion sensitivity, eliminating welding residual stress and improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present embodiment provides a kind of welding method that prevents SA335-T / P92 steel weld seam from heat-affected massive ferrite to produce, and it comprises the following steps:

[0028] (a) The material is T / P92 steel (specification ) and Super304H (Specification Process it into a wall thickness of 6.8mm before welding) Make grooves between the end faces of dissimilar steels;

[0029] (b) Carry out argon arc welding without preheating of the root layer, and then weld layer by layer until the weld is formed; welding parameters are shown in Table 1;

[0030] Welding parameters in table 1 embodiment 1

[0031] Process content Parameter requirements Groove V-shaped groove, the groove angle is 50° on one side pre-heat temperature no warm-up Welding current 160A arc voltage 16V interlayer temperature 150~200℃ welding speed 60~80mm / min Protective gas pure argon shielding gas flow 10-20L / min

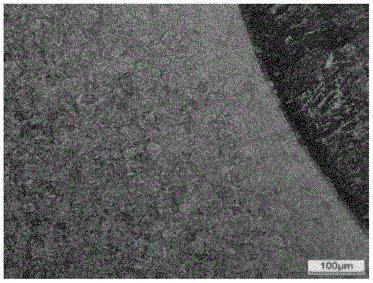

[003...

Embodiment 2

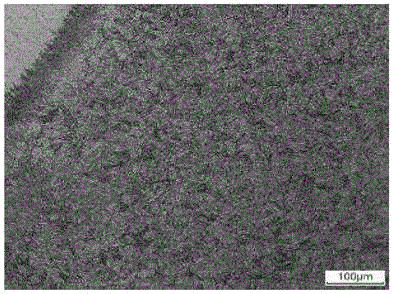

[0034] This embodiment provides a welding method for preventing the SA335-T / P92 steel weld seam from being affected by the blocky ferrite produced by heat. Its specific operation steps and operating parameters are consistent with those in Embodiment 1. The difference is that the material is T / P92 steel (specification ) and HR3C (Specification Process it into a wall thickness of 6.8mm before welding) for welding; the metallographic structure of the heat-affected zone on the T / P92 side of the final welded product is as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com