A sludge recovery device

A recovery device and sludge technology, which is applied in manufacturing tools, grain processing, presses, etc., can solve the problems of poor visual effect of sludge model and rough surface of sludge model, and achieve soft plasticity, good viscosity, and less cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

[0019] The reference signs in the accompanying drawings of the specification include:

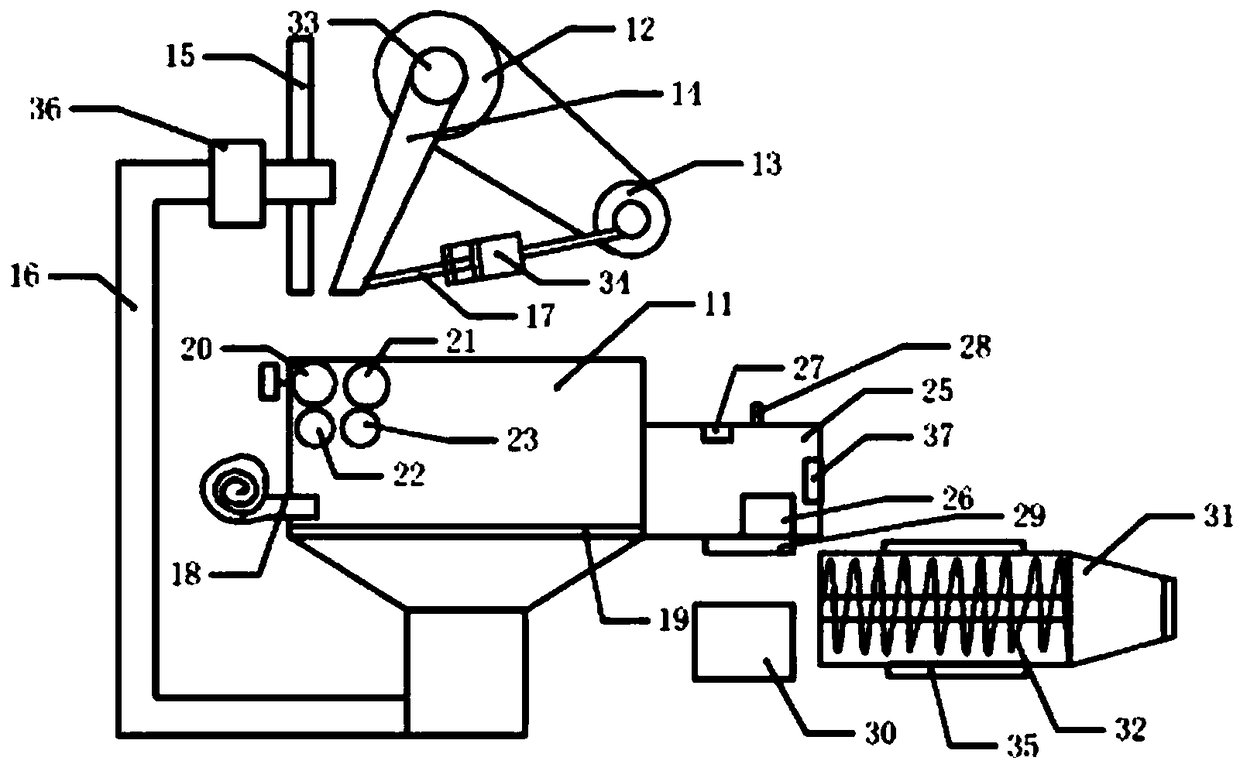

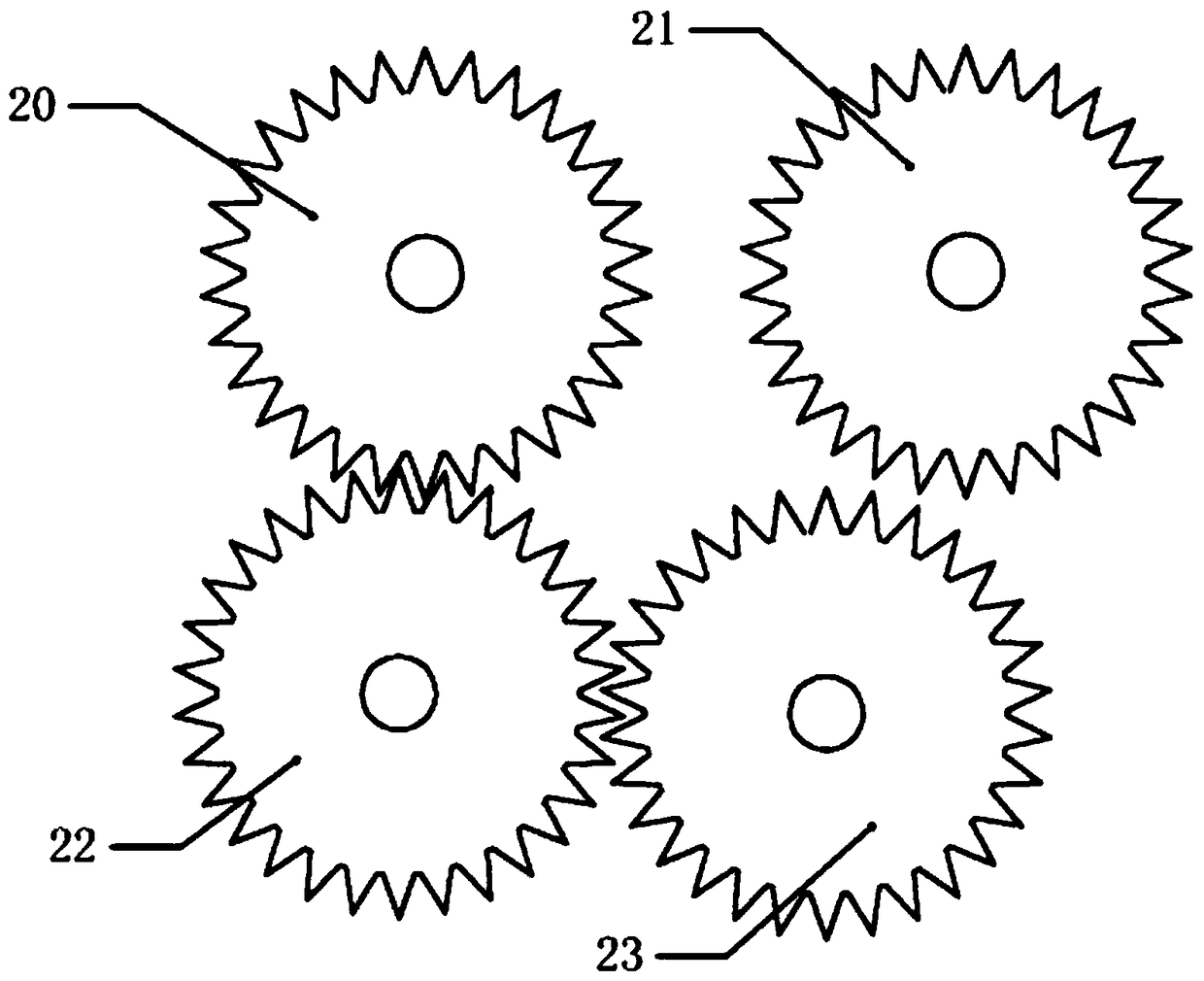

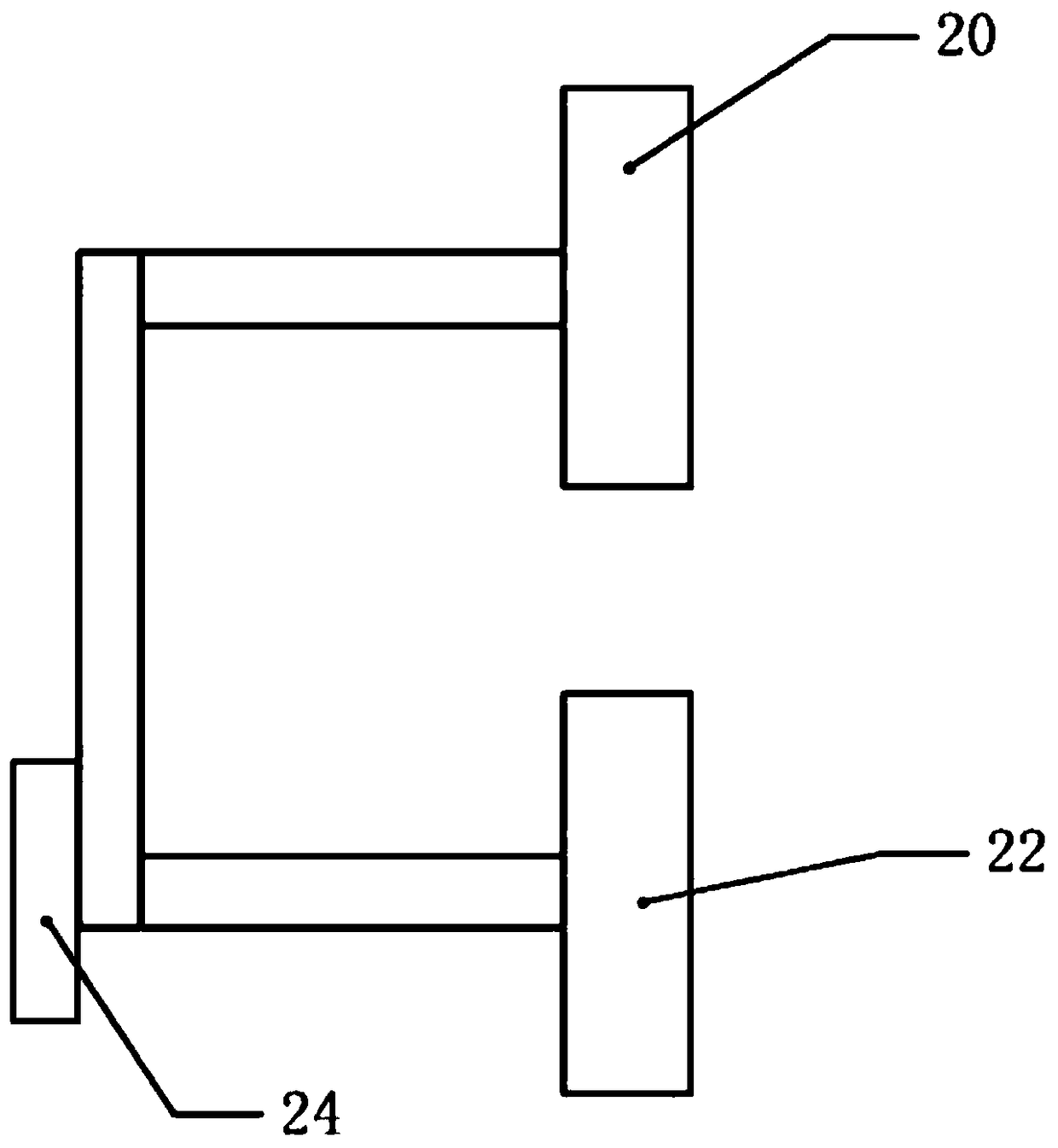

[0020] Sludge recovery bin 11, pulley 12, first motor 13, movable jaw plate 14, static jaw plate 15, return pipe 16, adjustment rod 17, blower 18, filter plate 19, first gear 20, second gear 21, second gear Three gears 22, fourth gear 23, second motor 24, miscellaneous removal box 25, magnet block 26, electromagnetic wave distance finder 27, alarm device 28, discharge door 29, collection bag 30, mud bin 31, screw rod 32, Eccentric shaft 33, adjustment box 34, heater 35, self-priming pump 36, sprayer 37.

[0021] Such as figure 1 The sludge recovery device shown includes a sludge recovery bin 11, and a jaw crusher is fixedly installed above the sludge recovery bin 11. The jaw crusher includes a pulley 12, a movable jaw plate 14, a static jaw plate 15, and a static jaw plate 15 Throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com