Utilize metal salt solution to reclaim EDTA metal complex and regenerate the method for chlorine type anion exchange resin

A metal salt solution and exchange resin technology, applied in ion exchange, ion exchange regeneration, preparation of organic compounds, etc., can solve the problems of poor resin regeneration effect, difficult treatment of concentrated waste liquid, and low recovery efficiency of EDTA metal complexes , to achieve good regeneration effect, reduce processing time and cost, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

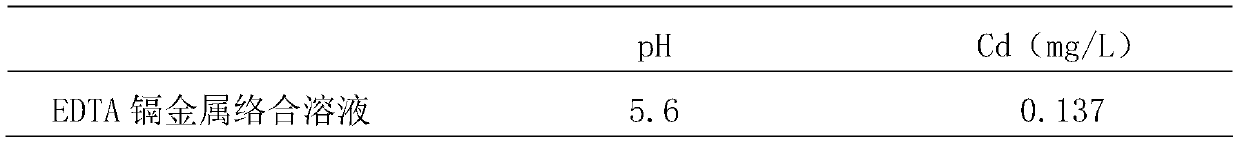

[0018] Example one: the soil used in the test is taken from the downstream farmland of Huanggu Village, Zhuzhou County, Hunan Province, and after mixing and stirring with Ca-EDTA solution, EDTA cadmium metal complex solution is obtained, and its basic physical and chemical properties are as shown in Table 1:

[0019] Table 1 Physicochemical properties and cadmium metal content in waste liquid

[0020]

[0021] The specific method is:

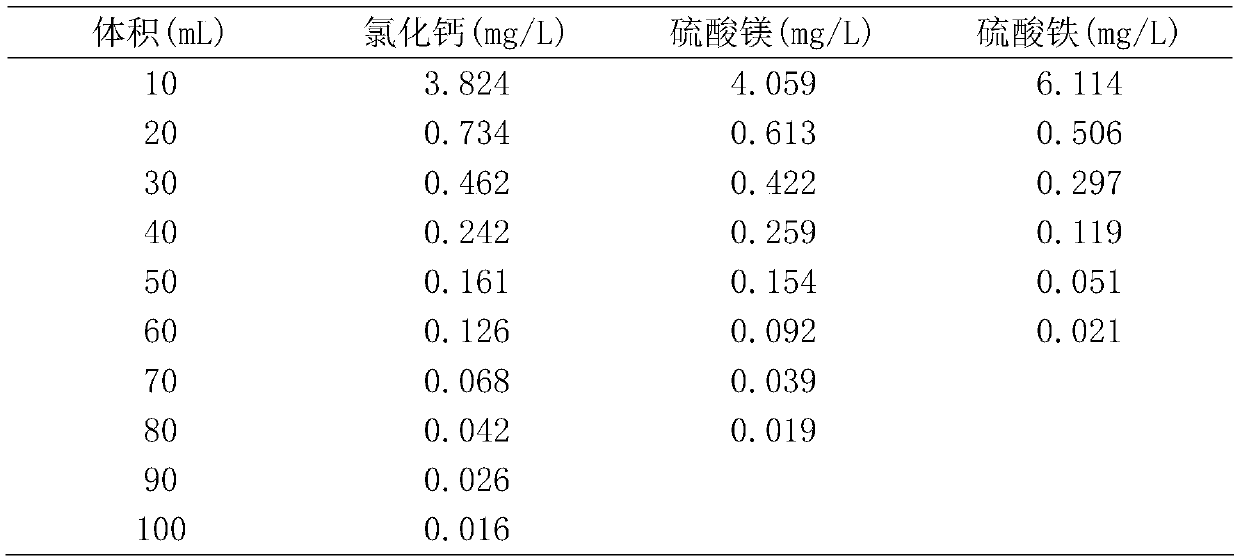

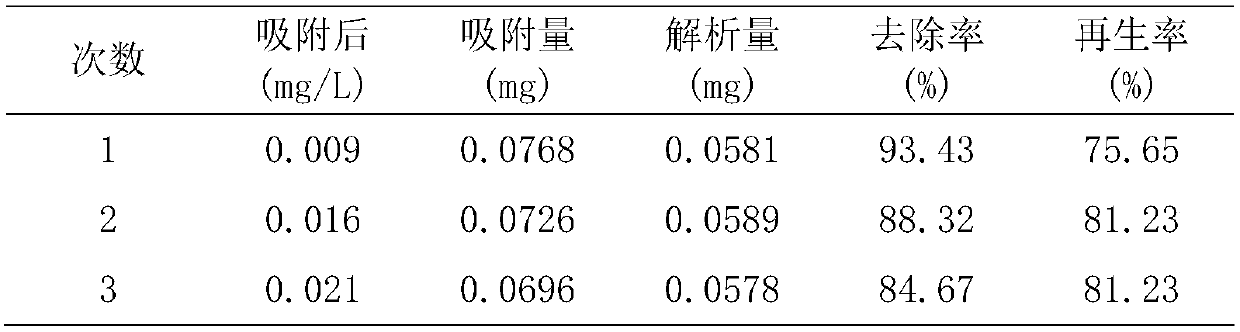

[0022] (1) Dynamic column adsorption: Precisely weigh 2.0g of chlorine-type anion exchange resin and put it into a glass chromatography column with a diameter-to-height ratio of 2.5-15, so that the resin layer height is 30mm, and put glass wool into the glass chromatography column At the top, at a constant temperature (25°C), use the obtained EDTA cadmium metal complex solution as an adsorption solution, use a constant flow pump to pump it into the glass chromatography column, and pass through the glass chromatography column from the top of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com