A conductive surface treatment method before electroplating of abs plastics

An ABS plastic and surface treatment technology, applied in the field of graphene technology and plastic surface treatment, can solve the problems of limited application range, non-wear resistance, narrow applicability, etc., achieve simplified conductive treatment process, simple and easy preparation process, The effect of simplifying the pre-plating process

Active Publication Date: 2022-06-10

HUAQIAO UNIVERSITY +1

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, plastic also has certain disadvantages: non-conductive, non-thermal, non-wear-resistant, easy to deform, not resistant to pollution, lack of metallic luster and aesthetics, etc., which limits its scope of use to a certain extent

However, considering the dispersion of graphene materials in the resin matrix, this method is only applicable to graphene oxide and its derivatives as inorganic fillers, and its applicability is narrow.

Moreover, the conductivity of the plastic workpiece prepared by this method has not been significantly improved, only many micropores have been formed on the surface of the plastic workpiece, and the roughening step has been mainly omitted in the electroplating process. Fully utilized in the plastic plating process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

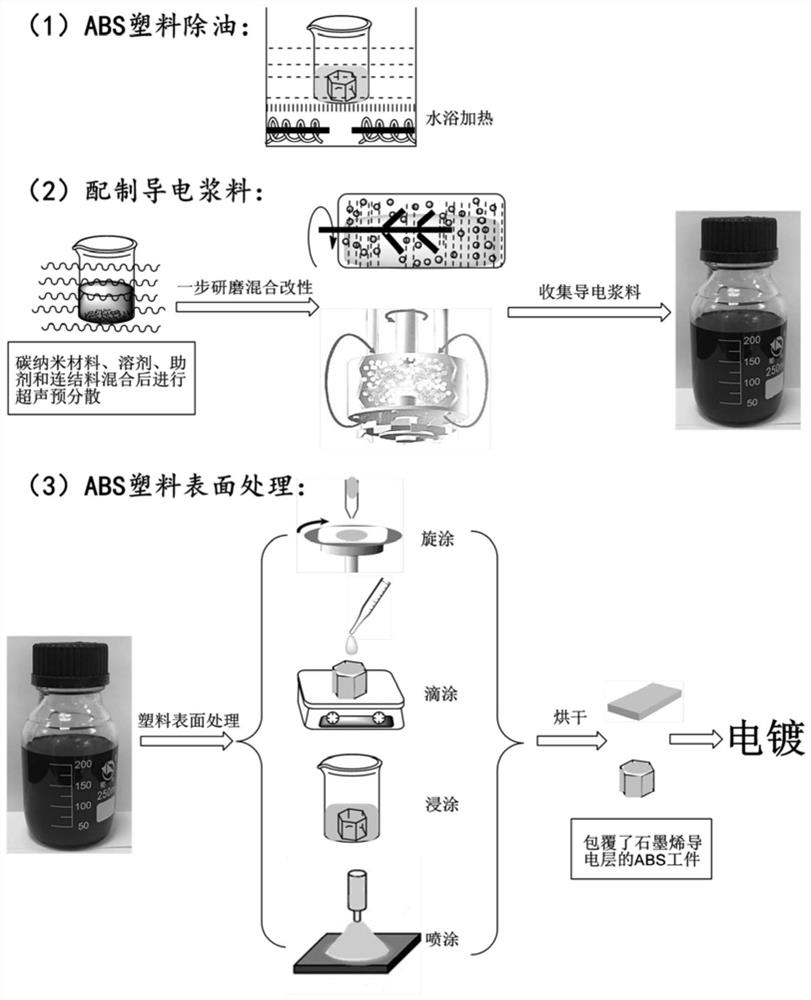

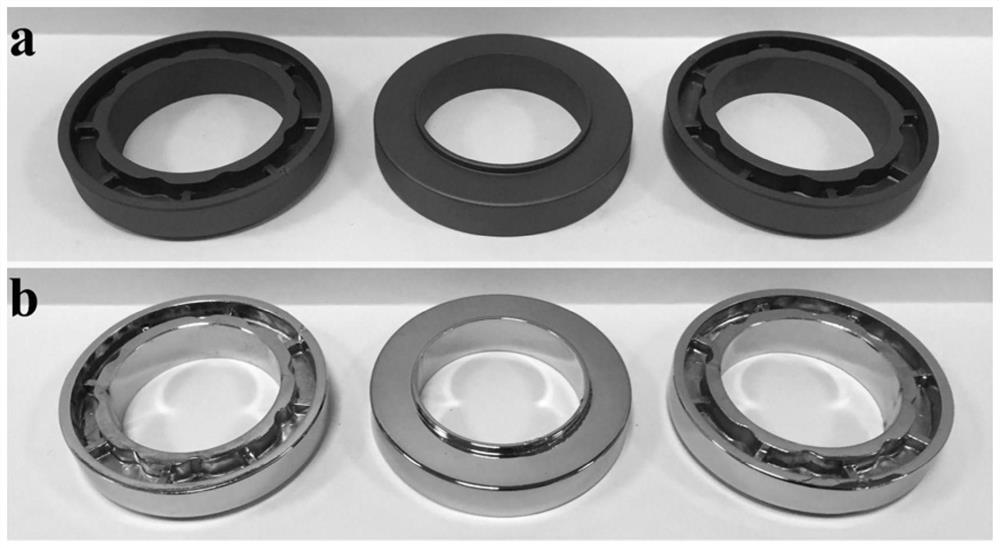

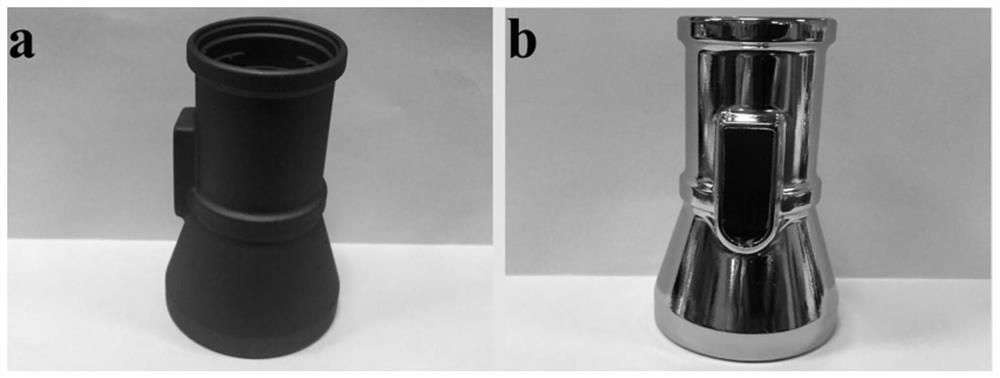

The invention discloses a conductive surface treatment method before electroplating of ABS plastics, which uses the excellent conductivity and film-forming properties of graphene microchips to directly coat graphene coatings on the surface of plastic products by certain means to endow insulating ABS. Plastic surfaces have a certain conductivity. The ABS plastic coated with a graphene conductive layer on the surface prepared by the method of the present invention can be directly electroplated, which saves complex and cumbersome procedures such as roughening, sensitization, activation, and chemical plating in the traditional process, and is safer, more environmentally friendly, The method is simple and easy, and greatly shortens the technological process and cost, and is suitable for industrialized electroplating of ABS plastics of different shapes and sizes, and has important practical application value. The graphene conductive layer coated on the ABS plastic surface by the method of the invention is uniform and continuous, has good adhesion, and can be directly electroplated.

Description

A kind of conductive surface treatment method before electroplating of ABS plastic technical field The invention belongs to graphene technology and plastic surface treatment technical field, be specifically related to a kind of ABS plastic before electroplating The conductive surface treatment method. Background technique In recent years, with the advancement of science and technology and the continuous emergence of new materials, non-metallic materials such as plastics, glass, ceramics, gypsum, etc. Metal materials are more and more widely used in industry and daily life, and many products previously made of metal are now plasticized. These have greatly reduced the weight and cost of the product. But plastic also has certain disadvantages: non-conductive, It is not thermally conductive, not wear-resistant, easily deformed, not resistant to pollution, lacks metallic luster and aesthetics, which limits its use to a certain extent. range of use. If a layer of metal...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C25D5/56C25D5/00

Inventor 陈国华许传凯肖平生刘飞翔刘泉根

Owner HUAQIAO UNIVERSITY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com