VOCs (volatile organic chemcials) catalytic combustion integral catalyst and preparation method thereof

A monolithic catalyst, catalytic combustion technology, applied in catalyst activation/preparation, combustion method, physical/chemical process catalyst, etc. Sintering performance, improving surface acidity, inhibiting the effect of anti-SO2 poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

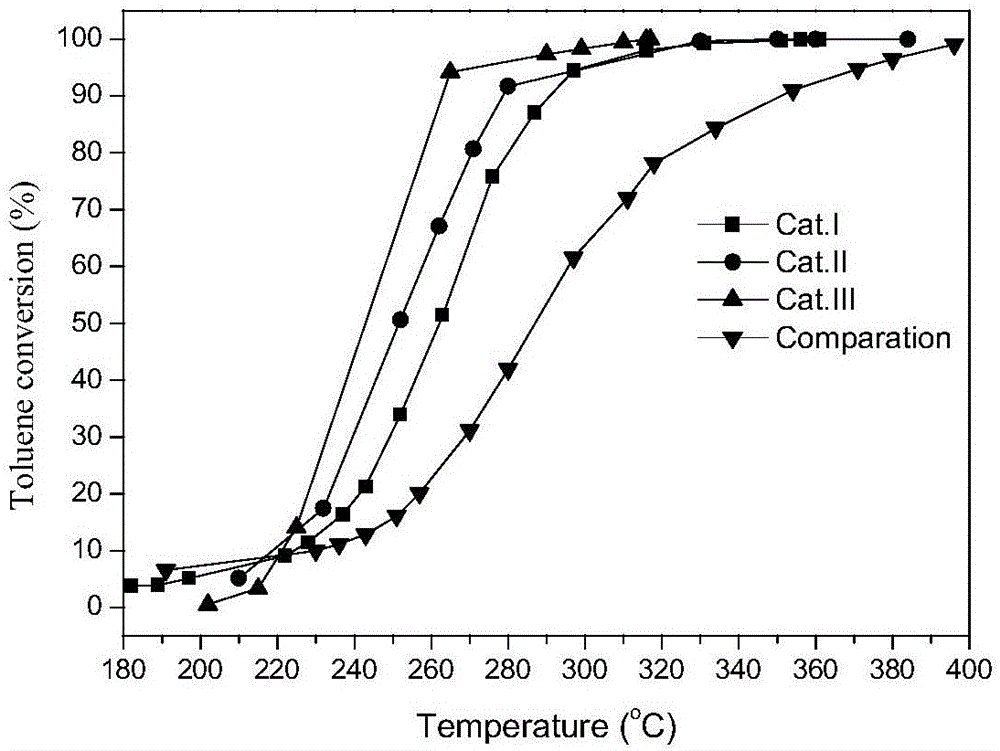

Examples

Embodiment 1

[0028] The preparation steps of present embodiment catalyst are as follows:

[0029] 1) Cut a commercially available cordierite honeycomb carrier with a hole number of 200 holes / square inch into Φ20*40mm samples (mass about 10g), soak them in 200mL, 0.5% (wt%) dilute nitric acid solution for 20h, take them out, and use Wash it several times with deionized water until it becomes neutral, dry it in an oven at 110°C for 4 hours, and take it out for use.

[0030] 2) γ-Al 2 o 3 Preparation of the carrier: 100g of commercially available pseudo-boehmite (preferably Shandong Aluminum Industry Model A-AS-HC-PHP-08) is added to the ball mill jar, and the nitrates of Ce, Zr, La, Ba are than CeO 2 : ZrO 2 : La 2 o 3: BaO=0.3:0.7:0.2:0.1 is made into the aqueous solution of 38.25g 60% (wt%), and the consumption of soluble salt also adds in this ball mill jar according to total oxide 10g, then slowly adds 300ml 5% (wt%) %), sealed ball mill for 1 hour, took out the slurry and aged it...

Embodiment 2

[0036] In this example, a cordierite honeycomb carrier with the same specifications was prepared by the same method as in Example 1 for future use.

[0037] γ-Al 2 o 3 Preparation of carrier: the preparation method is the same as in Example 1, except that the nitrate of Ce, Zr, La, Ba is CeO in the molar ratio of oxide 2 : ZrO 2 : La 2 o 3 : BaO=0.5:0.5:0.2:0.1 is made into the aqueous solution of 36.12g 60% (wt%), and the consumption of soluble salt is calculated according to total oxide 10g, makes specific surface area 215m 2 / g γ-Al 2 o 3 carrier.

[0038] Catalyst powder preparation: the preparation method and the amount of active components are the same as in Example 1, and finally a stable catalyst active powder is obtained, wherein the mass ratio of Pd to the carrier material is 0.3%.

[0039] The preparation and coating method of the catalyst coating are the same as in Example 1, and the finally obtained catalyst is designated as Catalyst II (Cat. II).

[0040...

Embodiment 3

[0042] In this example, a cordierite honeycomb carrier with the same specifications was prepared by the same method as in Example 1 for future use.

[0043] The preparation method of the first carrier: γ-Al 2 o 3 Preparation of carrier: the preparation method is the same as in Example 1, except that the nitrate of Ce, Zr, La, Ba is CeO in the molar ratio of oxide 2 : ZrO 2 : La 2 o 3 : BaO=0.9:0.1:0.2:0.1 is made into the aqueous solution of 32.43g 60% (wt%), and the consumption of soluble salt is calculated according to total oxide 10g, makes specific surface area 225m 2 / g γ-Al 2 o 3 carrier.

[0044] The catalyst powder, coating and coating are the same as in Example 1, and the finally obtained catalyst is designated as Catalyst III (Cat. III).

[0045] The composition of catalyst III (Cat.III) in this example is: 84.4 parts of cordierite honeycomb ceramic carrier, γ-Al 2 o 3 13.6 parts, 1.5 parts of oxide additives, 0.04 parts of active ingredient Pd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com