Method for preparing silk fibroin nanosphere

A technology of silk fibroin and nanospheres, applied in the field of biomedicine, can solve the problems of high equipment requirements, introduction of organic impurities, low yield, etc., and achieve the effects of improving biological safety, simple and easy-to-obtain equipment, and small environmental impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

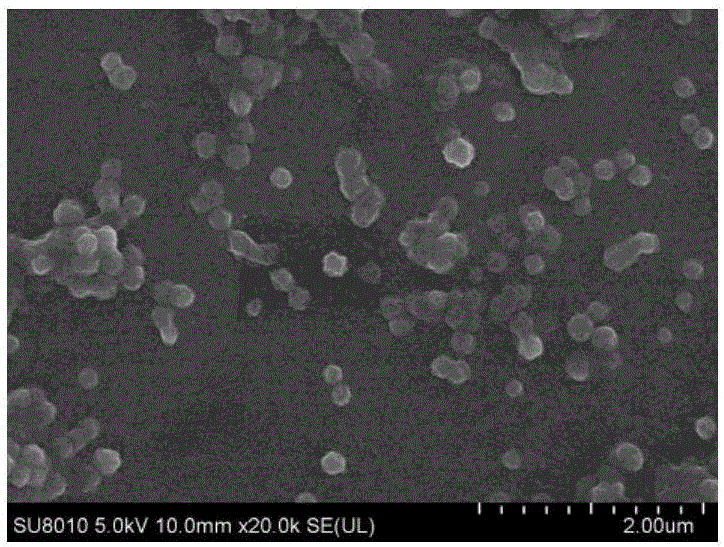

Image

Examples

Embodiment 1

[0026] Cut 50g of silkworm cocoons into pieces, put them into 5L boiling aqueous solution of 0.2% anhydrous sodium carbonate, continue to boil for 90 minutes for degumming treatment, filter, collect filter cake, and repeatedly wash with deionized water for 5 times to remove surface residues The sodium carbonate, after drying at 50 ℃, is silk fibroin fiber. Dissolve the dried silk fibroin fibers in 250 mL of a 9.3 mol / L lithium bromide aqueous solution (65°C), and after complete dissolution, put the silk fibroin solution into a dialysis bag (molecular weight cut-off: 3500), and dialyze it in deionized water for 3 days , Change the water twice a day to remove lithium bromide. The silk fibroin aqueous solution obtained after dialysis was adjusted to a mass concentration of 1% with deionized water.

[0027] Anhydrous ethanol was pre-cooled in a refrigerator at 4°C for 1 hour. Take 10 mL of absolute ethanol and add it to 100 mL of silk fibroin aqueous solution with a mass concent...

Embodiment 2

[0029] Cut 50g of tussah cocoons into pieces, put them into 5L of boiling mass concentration 0.2% anhydrous sodium carbonate aqueous solution, continue to boil for 120 minutes to carry out degumming treatment, filter, collect filter cake, and repeatedly wash the obtained silk fibroin fibers with deionized water 5 After removing the residual sodium carbonate on the surface, and drying at 50 °C, it is silk fibroin fiber. Dissolve the dried silk fibroin fibers in 500 ml of a ternary solution at 70°C (the volume ratio of calcium chloride / ethanol / water is 1:2:8), and after complete dissolution, put the silk fibroin solution into a dialysis bag ( Molecular weight cut-off: 3500), dialyzed in deionized water for 4 days, and changed the water twice a day to remove residual solvent. The silk fibroin aqueous solution obtained after dialysis was adjusted to a mass concentration of 5% with deionized water.

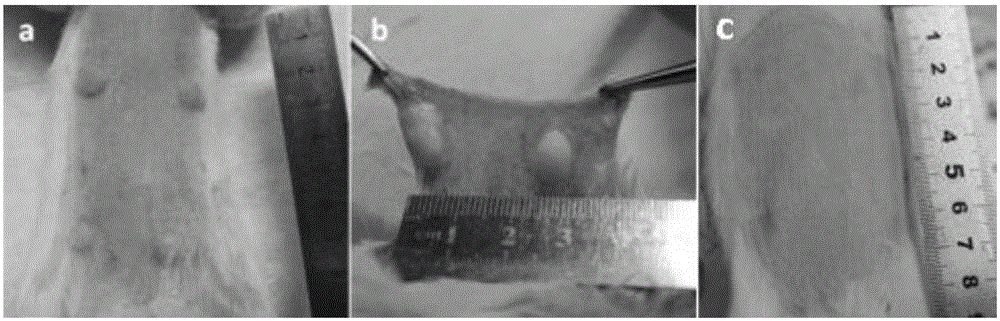

[0030] 5 μg of bFGF-2 was dissolved in 100 mL of silk fibroin aqueous solution wi...

Embodiment 3

[0033] Put 50g of silkworm raw silk into 5L of boiling 0.2% anhydrous sodium carbonate aqueous solution, continue to boil for 60 minutes to carry out degumming treatment, filter, take filter cake, repeatedly wash with deionized water and deionized water for 5 times to remove surface residues The sodium carbonate, after drying at 50 ℃, is silk fibroin fiber. Dissolve the dried silk fibroin fibers in 500 ml of a ternary solution at 70°C (the volume ratio of calcium chloride / ethanol / water is 1:2:8), and after complete dissolution, put the silk fibroin solution into a dialysis bag ( Molecular weight cut-off: 3500), dialyzed in deionized water for 4 days, and changed the water twice a day to remove residual solvent. The silk fibroin aqueous solution obtained after dialysis was adjusted to a mass concentration of 2% with deionized water.

[0034] Dissolve 1 μg of BMP-2 in a 2% mass concentration, 100 mL silk fibroin aqueous solution, and mix at 4° C. and 30 rpm for 30 minutes to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com