Method for reducing oil content of oil-fried potato strips

A potato and frying technology, applied in food coating, food science, preservation of fruits/vegetables through bleaching, etc., can solve the problems of insignificant oil reduction effect, reduce oil content of potato chips, etc., and achieve the goal of reducing oil content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

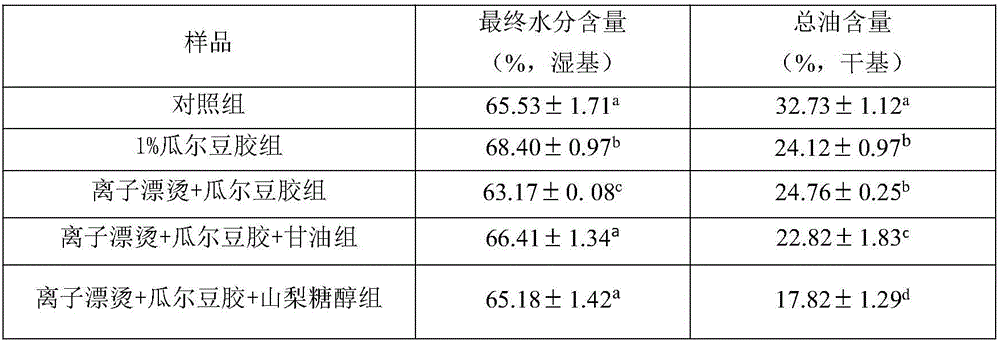

[0025] Ionic blanching + guar gum + sorbitol group: wash and peel the potatoes, cut them into uniform French fries with a size of 8×8×60mm, and put them in 0.5% calcium ion solution at 95°C 4min blanching, after blanching, put it in a cold water bath, take out the sample to remove excess water on the surface, then transfer the sample to a mixed solution of 1% guar gum and 3% sorbitol, and coat it at 45°C Film 3min. The above coating samples were cooled to room temperature, and fried at 170° C. for 3 minutes.

[0026] Control group: Potatoes were washed and peeled, cut into uniform potato fries with a size of 8×8×60 mm, blanched in 95°C water for 4 minutes, placed in a cold water bath after blanching, and the samples were taken out to remove excess water on the surface. Frying is carried out under the condition of 170° C., and the frying time is 3 minutes.

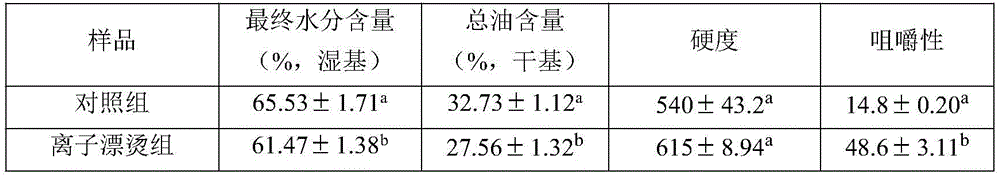

[0027] Ion blanching group: wash and peel the potatoes, cut them into uniform French fries with a size of 8×8×60mm, and...

Embodiment 2

[0037] Wash and peel the potatoes, cut them into uniform chips with a size of 8×8×60mm, and blanch them in a solution of 0.5% ions at 95°C for 4 minutes, place them in a cold water bath after blanching, and take out the samples Remove the excess moisture on the surface, then transfer the sample to a mixed solution of 1% guar gum and 3% sorbitol, and coat the film at 40°C for 4 minutes. The above coating samples were cooled to room temperature, and fried at 170° C. for 6 minutes. After the above-mentioned fried samples were dried to a constant temperature, the fat content in the fried samples was measured by a fat analyzer.

[0038] The final moisture content of the sample was (58.96±2.82%) and the total oil content (21.5±1.32%).

Embodiment 3

[0040]Wash and peel the potatoes, cut them into uniform French fries with a size of 8×8×60 mm, blanch them in a solution of 0.5% ion concentration at 95° C. for 4 minutes, and place them in a cold water bath after blanching. Take out the sample to remove excess moisture on the surface, then transfer the sample to a mixed solution of 1% guar gum and 3% sorbitol, and coat the film at 45°C for 5 minutes. The above coating samples were cooled to room temperature, and fried at 170° C. for 3 minutes.

[0041] After the above-mentioned fried samples were dried to a constant temperature, the fat content in the fried samples was measured by a fat analyzer. The final moisture content of the sample was (65.25±0.35%), and the total oil content was (19.79±1.65%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com