Technology for removing caffeine in tea

A caffeine-based technology, applied in the field of separation technology research and natural product extraction, can solve the problems of environmental pollution, expensive equipment, easy residual organic solvents, etc., and achieve the effect of convenient drinking, low-cost equipment, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Take 3 kg of commercially available Maojian green tea, add 4 to 12 liters of distilled water, heat to boiling, keep for 15 minutes, cool to about 50°C and filter under reduced pressure. Then add an appropriate amount of distilled water (leaves just submerged) to the tea leaves, do the same thing twice, and combine the filtrates.

[0020] (2) Add the filtrate to a well-balanced MCI-GEL chromatographic column, let the extract flow down naturally, and collect the effluent.

[0021] (3) Elute the chromatographic column with an appropriate ratio of ethanol-water system, and the eluate is basically caffeine, which is collected separately.

[0022] (4) Elute the chromatographic column after step 3 with pure ethanol, collect the eluate and combine it with the eluate from step 2, and concentrate to dryness under reduced pressure to obtain about 400 g of extract, which is pulverized.

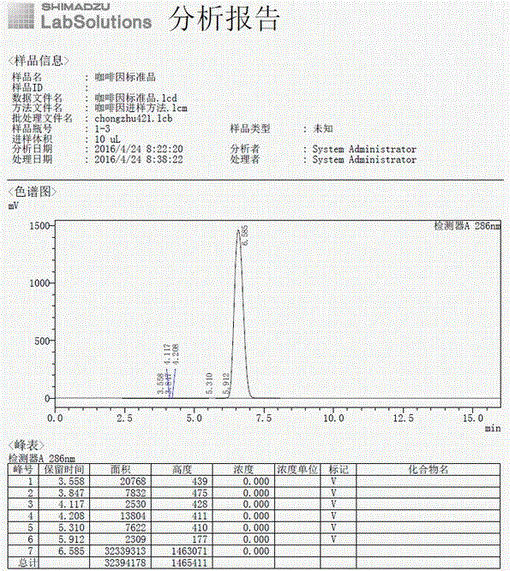

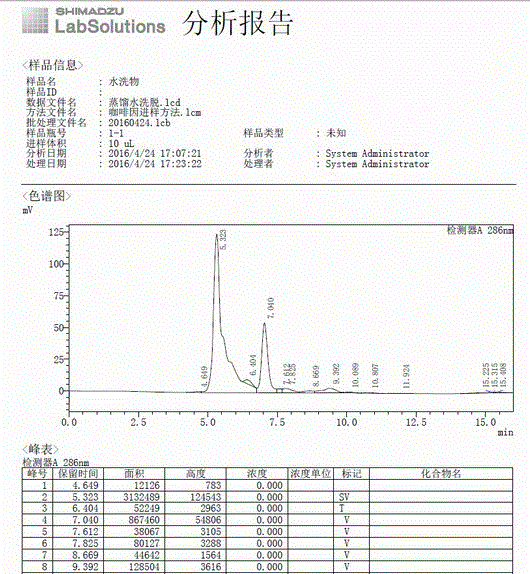

[0023] (5) No caffeine peak was detected in the obtained sample by the aforementioned HPLC...

Embodiment 2

[0025] (1) Take 4 kg of commercially available Longjing green tea, add 12-16 liters of distilled water, heat to boiling, keep for 15 minutes, cool to about 50°C and filter under reduced pressure. Then add an appropriate amount of distilled water (leaves just submerged) to the tea leaves, do the same thing twice, and combine the filtrates.

[0026] (2) Add the filtrate to a well-balanced MCI-GEL chromatographic column, let the extract flow down naturally, and collect the effluent.

[0027] (3) Elute the chromatographic column with an appropriate ratio of ethanol-water system, and collect the high-concentration caffeine solution separately.

[0028] (4) Elute the chromatographic column after step 3 with pure ethanol, collect the eluate, combine it with the eluate from step 2, and concentrate to dryness under reduced pressure to obtain about 500 grams of extract, which is pulverized.

[0029] (5) No caffeine peak was detected in the obtained sample by the aforementioned HPLC met...

Embodiment 3

[0031] (1) Take 3 kg of commercially available black tea, add 4 to 12 liters of distilled water, heat to boiling, keep for 15 minutes, cool to about 50°C and filter under reduced pressure. Then add an appropriate amount of distilled water (leaves just submerged) to the tea leaves, do the same thing twice, and combine the filtrates.

[0032] (2) Add the filtrate to a well-balanced MCI-GEL chromatographic column, let the extract flow down naturally, and collect the effluent.

[0033] (3) Elute the chromatographic column with an appropriate ratio of ethanol-water system, and the eluate is basically caffeine, which is collected separately.

[0034] (4) Elute the chromatographic column after step 3 with pure ethanol, collect the eluate and combine it with the eluate from step 2, and concentrate to dryness under reduced pressure to obtain about 400 g of extract, which is pulverized.

[0035] (5) No caffeine peak was detected in the obtained sample by the aforementioned HPLC method....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com