Paper mulberry ensilage direct harvesting baler

A technology for balers and paper mulberry, applied in the direction of balers, harvesters, chassis of agricultural machinery, etc., can solve the problems of hard stems, not easy to harvest, transport, cut and rub, etc., and achieve convenient cutting and rubbing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

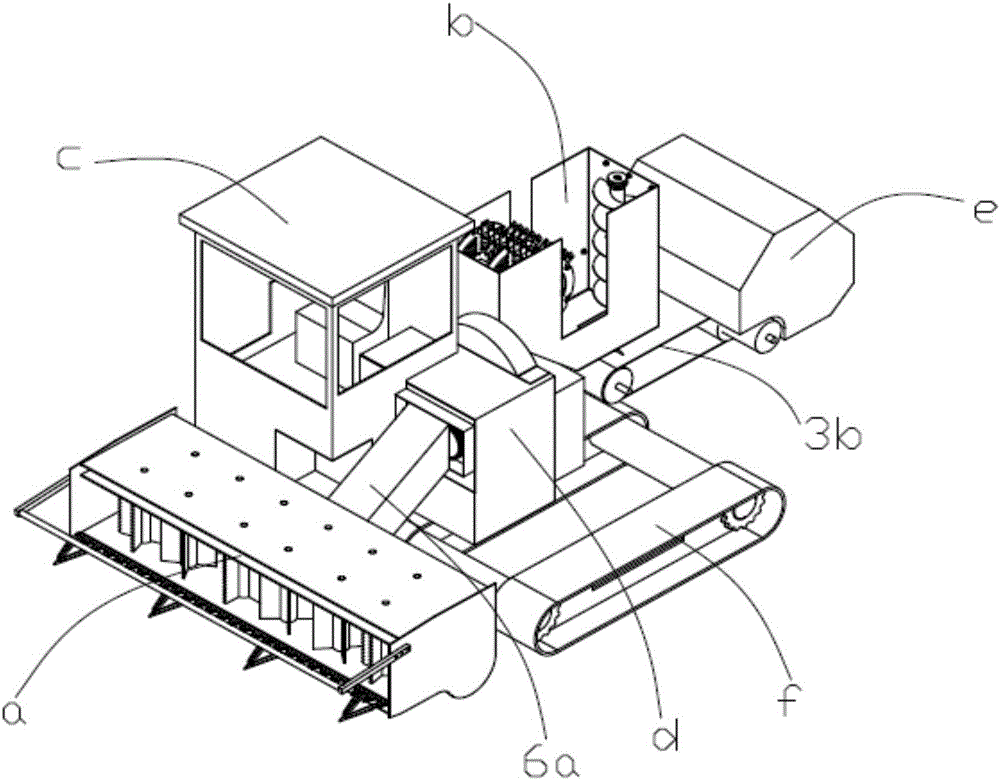

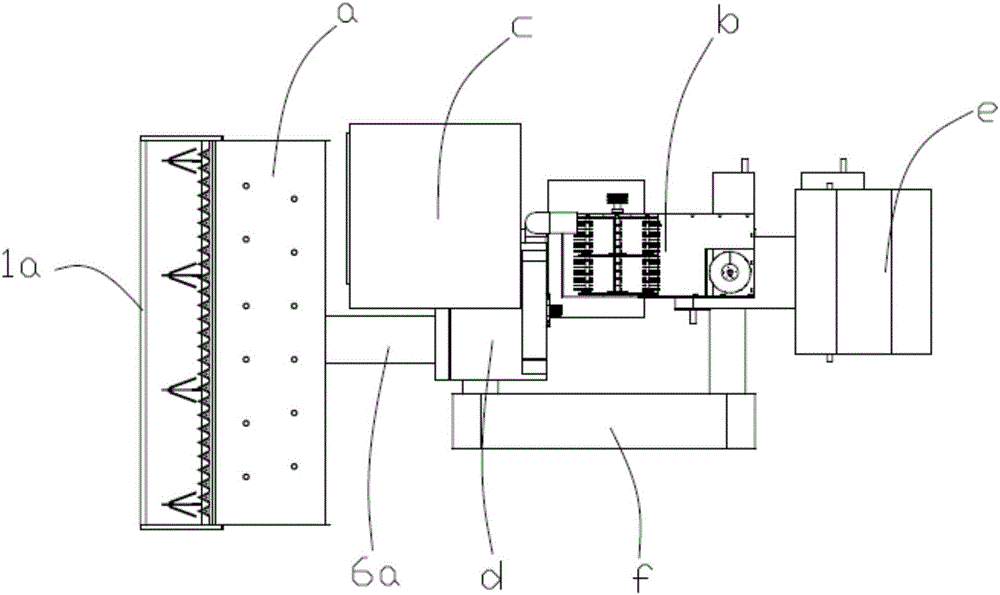

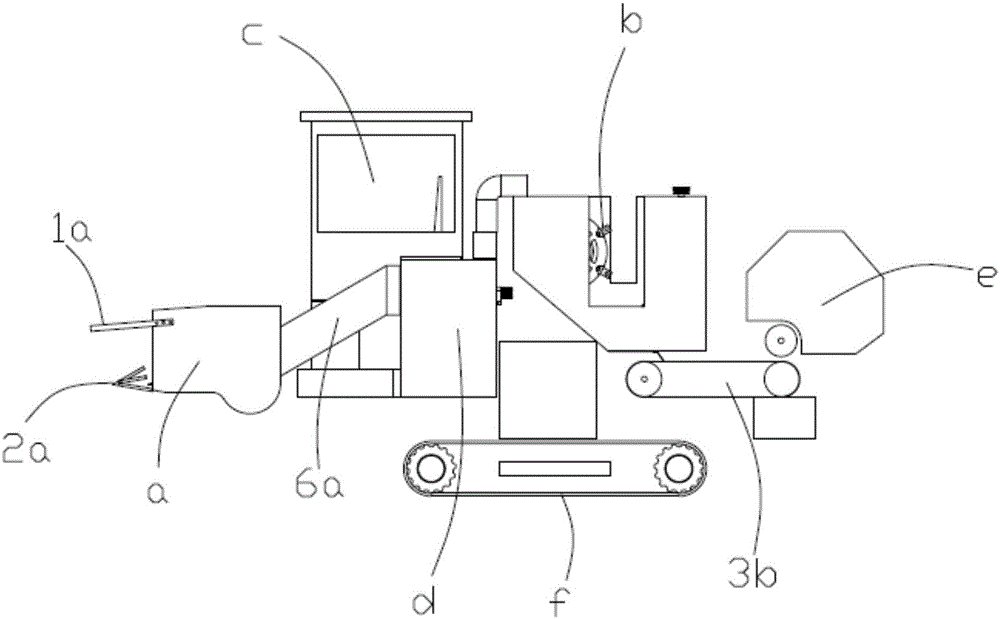

[0049] Such as Figure 1-3 As shown, the present invention includes a header assembly a, a secondary kneading conveying mechanism b, a cab assembly c, a fan assembly d, a baler assembly e and a crawler-type walking assembly f. The header assembly a harvests the mulberry tree and feeds it through the feed wheel assembly. Then it enters the fan assembly d after being extruded by the bridge assembly. The fan assembly d is provided with cutting knife I, cutting knife II and fan blades with kneading function. After being finely cut by the cutting knife II, it is cut into sections of about 25mm, and then it is sent to the secondary kneading conveying mechanism b by the fan after being kneaded by the fan blades. After the feed additive is sprayed inside, it is pushed onto the conveyor belt by the propeller, and then the silage feed is transported to the baler assembly e by the conveyor belt for bundling. The mulberry tree is harvested 2-3 times a year as silage feed, and the harves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com