Rotary compressors and refrigeration cycle units

A rotary compressor and compression mechanism technology, applied in the field of rotary compressors and refrigeration cycle devices, can solve the problems of increased compression loss, increased noise, and inability to fully improve compression performance, so as to improve reliability and sound insulation The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

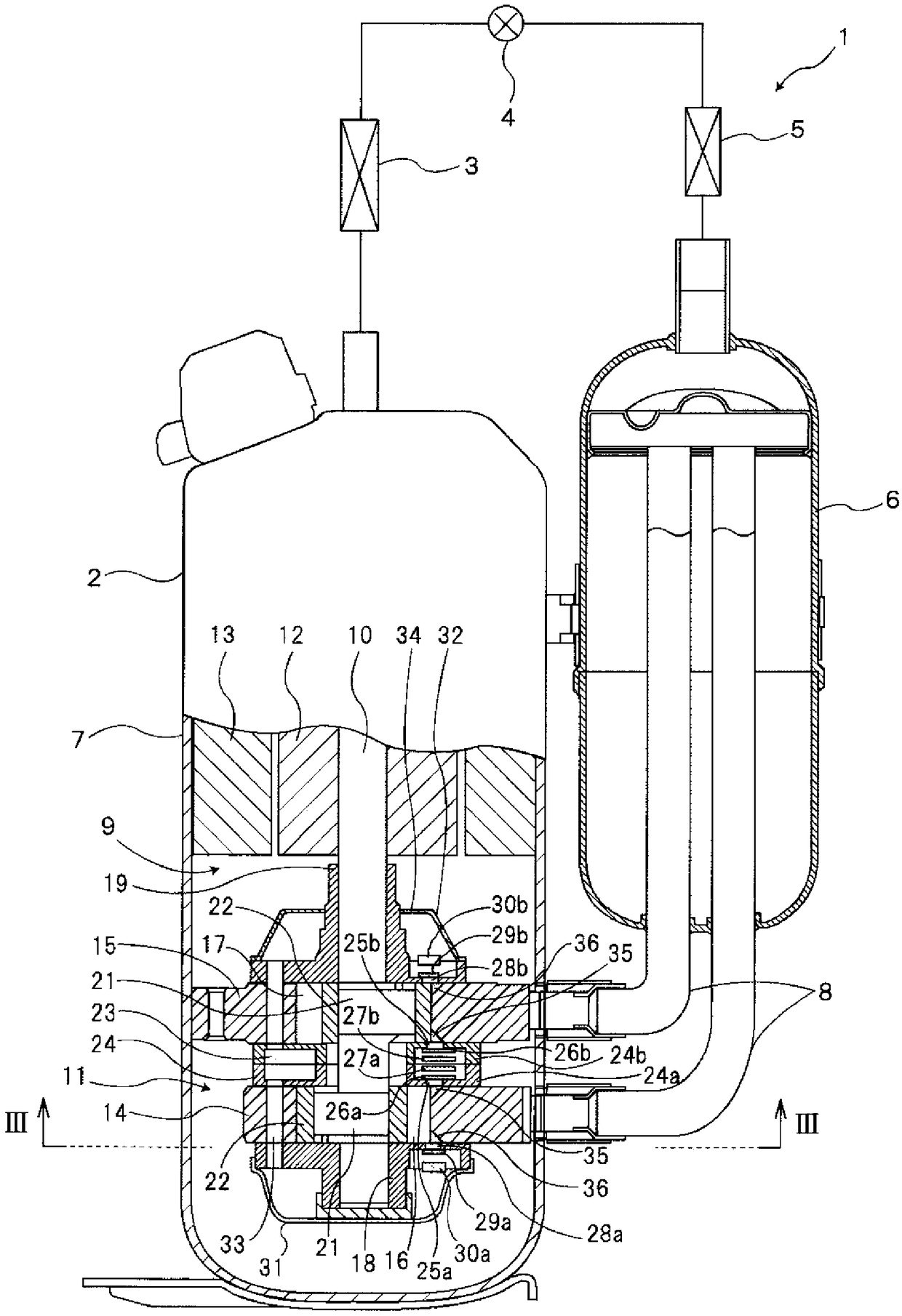

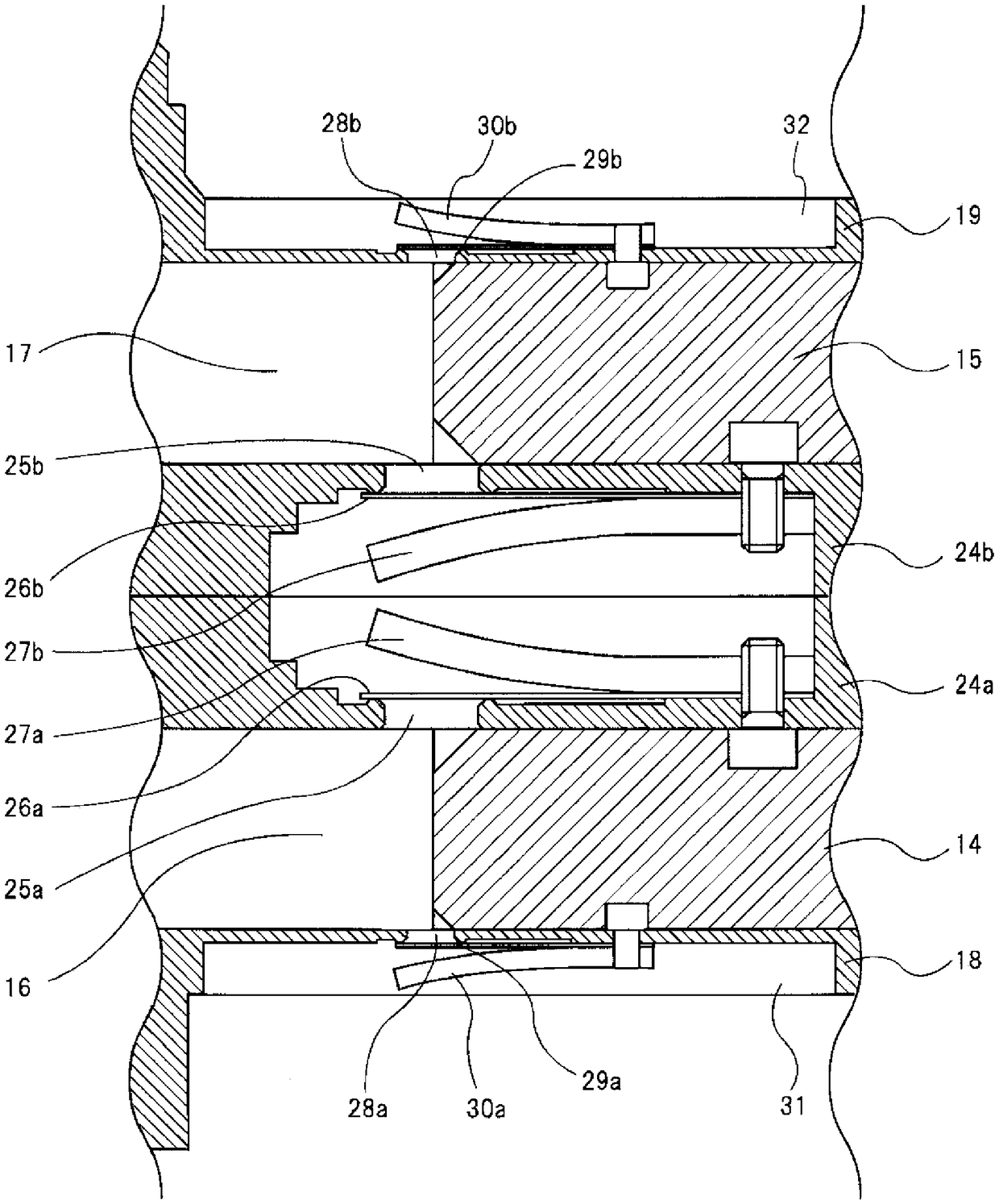

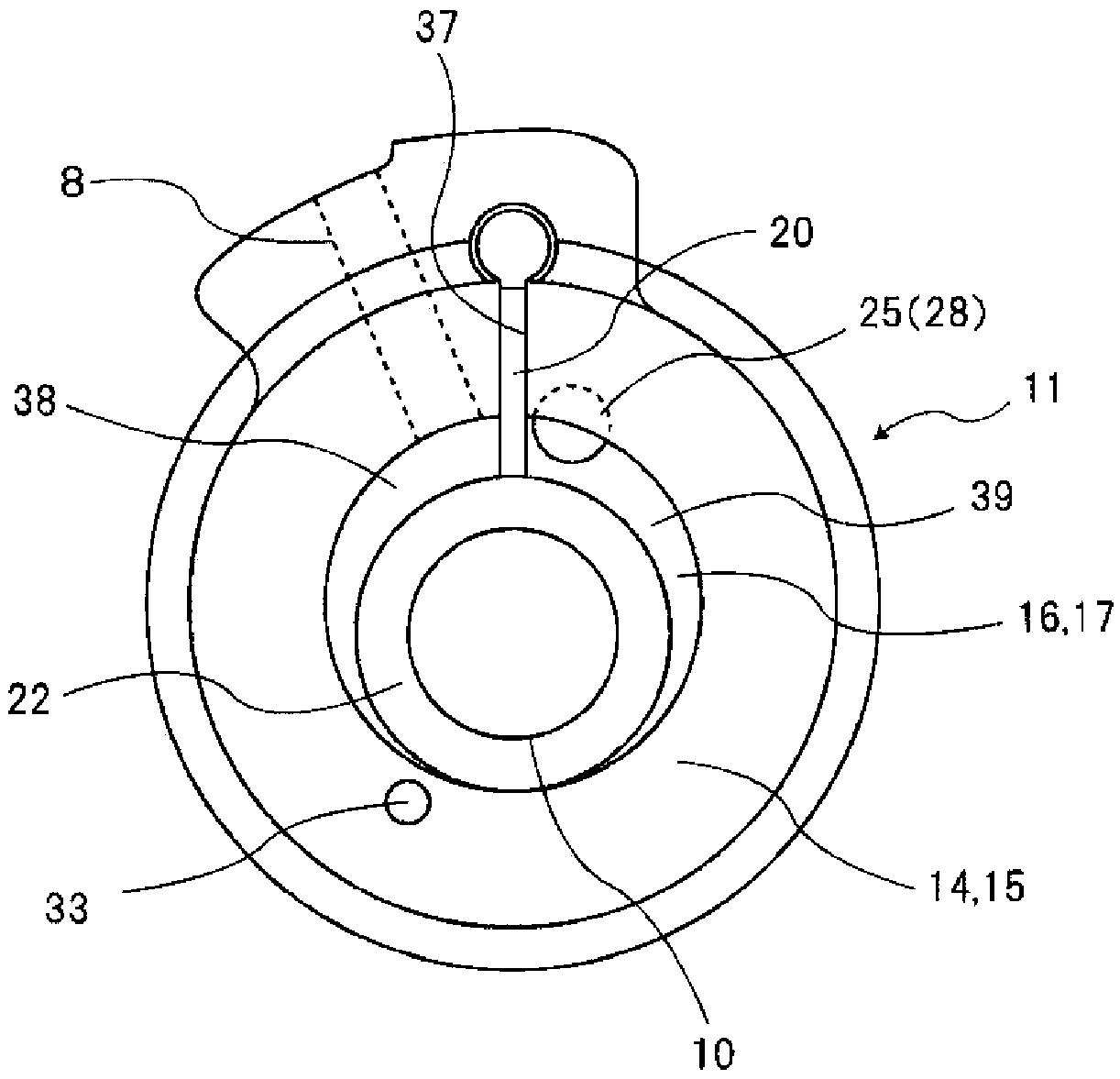

[0025] refer to Figure 1 to Figure 3 The rotary compressor of the first embodiment and the refrigeration cycle apparatus including the same will be described.

[0026] figure 1 The overall structure of the refrigeration cycle device is shown. The refrigeration cycle device 1 is provided with a compressor main body 2 connected to the compressor main body 2, and condenses gas refrigerant as a high-pressure and high-temperature working fluid discharged from the compressor main body 2 to convert it into a A condenser 3 for forming liquid refrigerant, an expansion device 4 connected to the condenser 3 to decompress the liquid refrigerant, an evaporator 5 for evaporating the liquid refrigerant expanded in the expansion device 4, and separating the refrigerant into gas phase and Accumulator 6 in liquid phase. The accumulator 6 and the compressor main body 2 are connected by the suction flow path 8 through which the working fluid flows, and constitute a rotary compressor.

[0027]...

no. 2 Embodiment approach

[0065] In the first embodiment, the case where the blades and the rollers of the compression mechanism are separate components has been described, but according to the present invention, as the second embodiment, an oscillating type (Japanese : Singtaip).

no. 3 Embodiment approach

[0067] In addition, the number of cylinders of the rotary compressor is two in the above example, but the same effect can be obtained also in a type having three or more cylinders as the third embodiment.

[0068] In addition, the present invention is an invention to provide a refrigeration cycle apparatus including the rotary compressor in each of the above-described embodiments, such as, for example, figure 1 As shown, it is composed of the following parts: the compressor main body 2 having the above-mentioned structure is connected to the compressor main body 2, and the high-pressure and high-temperature working fluid that is discharged from the compressor main body 2, that is, the gas refrigerant is condensed and turned into a liquid. A condenser 3 for the refrigerant, an expansion device 4 that decompresses the liquid refrigerant connected to the condenser 3, an evaporator 5 that evaporates the liquid refrigerant expanded by the expansion device 4, and an energy storage de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com