Lithium ion battery and anode plate thereof

A lithium-ion battery and anode sheet technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of increased side reactions at the interface between electrodes and electrolytes, reduced anode electrode potential, and poor operability. Effects of irreversible capacity loss, improved energy density, and improved cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

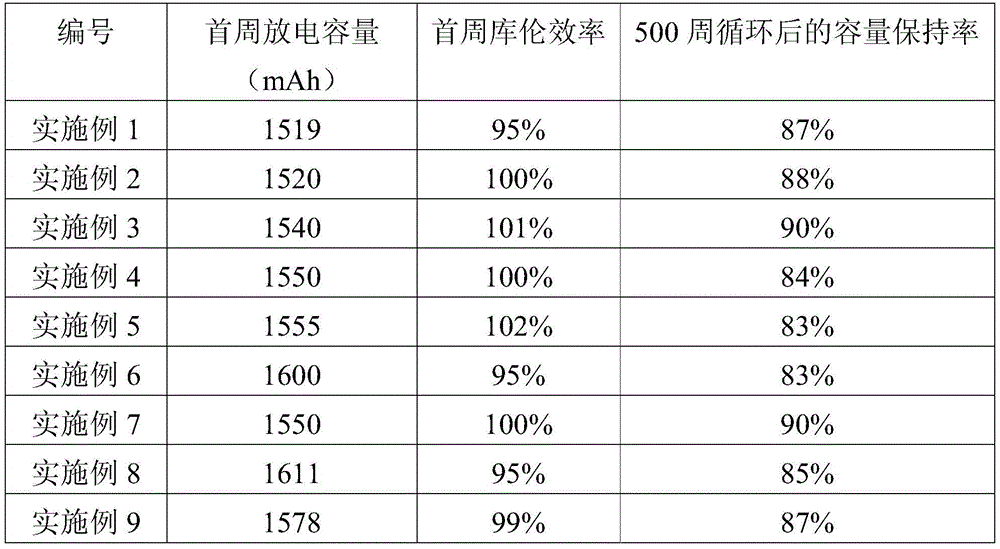

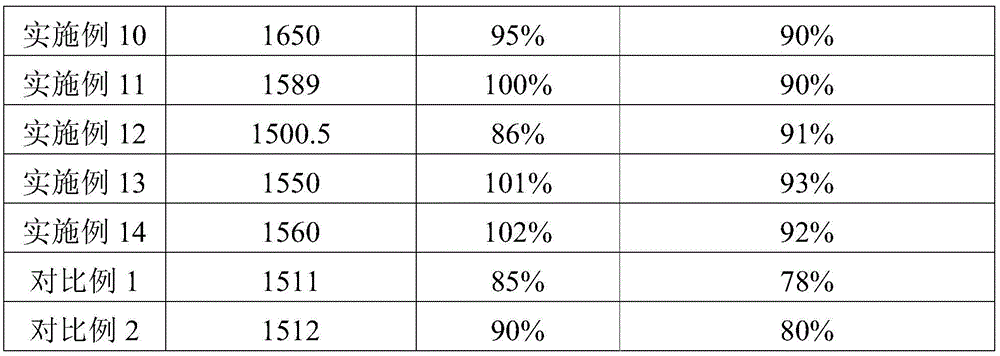

Examples

preparation example Construction

[0023] The preparation method of the first lithium-ion battery anode sheet includes the steps of: dissolving the anode active material, a conductive agent, a binder, and a lithium-containing compound in a solvent, stirring to obtain an anode slurry, and then uniformly coating the anode slurry on On the anode current collector, the lithium ion battery anode sheet is obtained after drying; wherein, the anode slurry is dried to form an anode active material layer. At this time, the lithium-containing compound may exist anywhere on the outer surface and inside of the anode active material layer.

[0024]In the first preparation method of lithium ion battery anode sheet, the solvent may be 1-methyl-2-pyrrolidone.

[0025] The preparation method of the second lithium-ion battery anode sheet includes the steps of: dissolving the anode active material, the conductive agent, and the binder in a solvent, stirring to obtain the anode slurry, and then uniformly coating the anode slurry on...

Embodiment 1

[0041] (1) Lithium nitride, graphite, acetylene black, sodium carboxymethyl cellulose, and styrene-butadiene rubber emulsion are dissolved in solvent 1-methyl-2-pyrrolidone in a weight ratio of 0.5:93.5:2:2:2. A uniform anode slurry is obtained by stirring, and then the anode slurry is evenly coated on the copper foil of the anode current collector, and the anode sheet of the lithium ion battery is obtained after drying, cold pressing, and slitting.

[0042] (2) Lithium manganate, acetylene black, and polyvinylidene fluoride are dissolved in the solvent 1-methyl-2-pyrrolidone in a weight ratio of 96:2:2, and a uniform cathode slurry is obtained by stirring, and then the cathode slurry is The material is evenly coated on the aluminum foil of the cathode current collector, and the cathode sheet of the lithium ion battery is obtained after drying, cold pressing and slitting.

[0043] (3) The lithium-ion battery anode sheet, lithium-ion battery cathode sheet, and PP / PE / PP three-la...

Embodiment 2

[0045] Lithium-ion batteries were made according to the method of Example 1, except for the following differences:

[0046] In step (1), the weight ratio of lithium nitride, graphite, acetylene black, sodium carboxymethyl cellulose, and styrene-butadiene rubber is 5:89:2:2:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com