Monodisperse magnetic porous silicon dioxide pellet and preparing method thereof

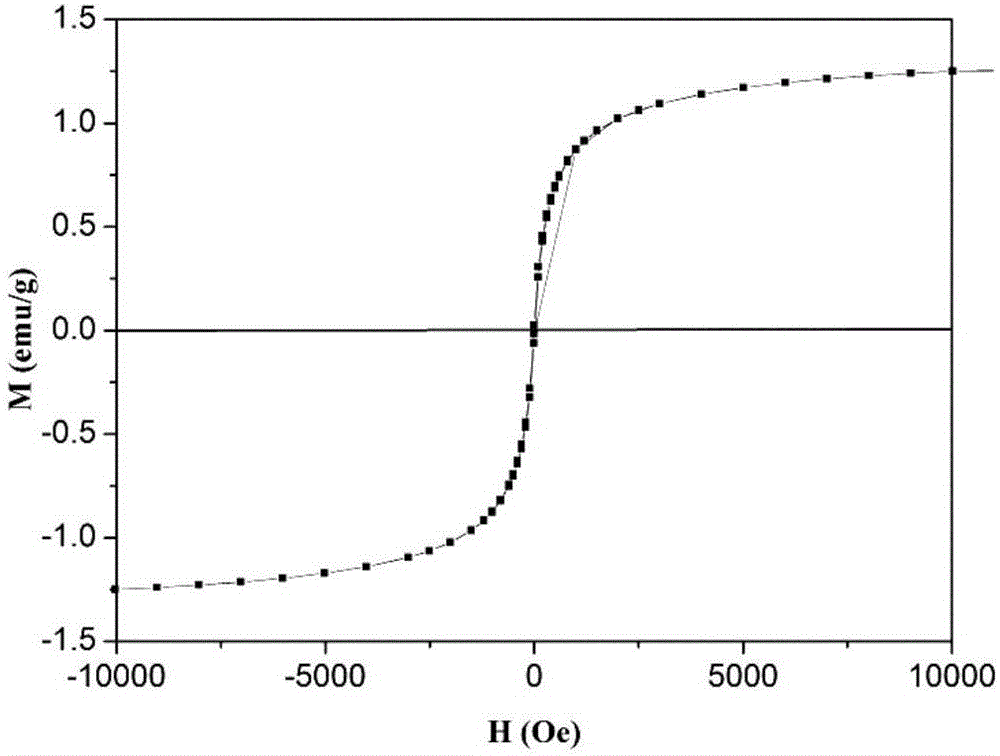

A technology of porous silicon dioxide and silicon dioxide, applied in the directions of silicon dioxide, silicon oxide, iron oxide, etc., can solve the problems of easy disappearance of magnetic properties, high temperature resistance, trouble, etc., and achieve easy operation, stable magnetic properties, and efficient preparation. effect of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this example, the commercially available monodisperse porous PGMA / EGDMA microspheres with a particle size of 4.54 μm were used as a template to prepare the monodisperse magnetic porous silica microspheres of this example. The specific preparation method is as follows:

[0039] (1) Weigh 20g of monodisperse porous PGMA / EGDMA microspheres with a particle size of 4.54μm and ultrasonically disperse them in 500mL of water, add 20g of sodium sulfite, stir mechanically at 160rpm, react for 24h, and carry out sulfonation; after the reaction, suction filter and wash with water and ethanol respectively 3 times, dry in a 50°C oven for later use.

[0040] (2) Configure Fe 2+ : Fe 3+ Iron source solution with a molar ratio of 1:2: weigh 1.645g FeCl 2 4H 2 O and 4.34 g FeCl 3 ·6H 2 Dissolve O in 20mL water to form an iron source solution. After the iron source solution is evacuated, N 2 Save it for future use. Ultrasonic disperse 0.5 g of the sulfonated PGMA / EGDMA microsphe...

Embodiment 2

[0049] In this example, commercially available monodisperse porous PGMA / EGDMA microspheres with a particle size of 7.42 μm were used as a template to replace the 4.54 μm monodisperse porous PGMA / EGDMA microspheres in Example 1 to prepare monodisperse magnetic porous silica microspheres. The preparation method of this example is compared with Example 1, the difference is that the addition of iron source solution in step (2) is 0.5mL; in step (4), 3g TEOS is dissolved in 10mL ethanol and is made into the ethanol solution of TEOS ; In step (5), 0.06g ceric ammonium nitrate is dissolved in 4mL acetone and is made into ceric ammonium nitrate solution; All the other steps and parameters are the same as in Example 1.

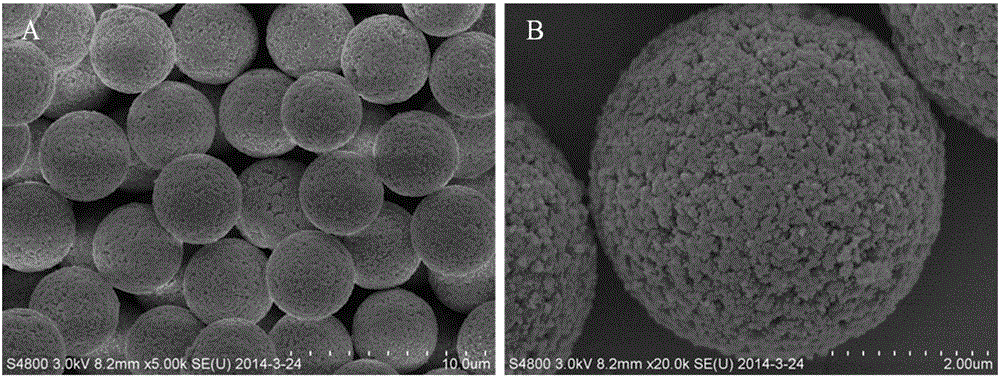

[0050] Using a scanning electron microscope to observe the monodisperse magnetic porous silica microspheres prepared in this example, the results show that this example prepared magnetic porous silica microspheres with uniform size and good monodispersity, and the magne...

Embodiment 3

[0052] In this example, the commercially available monodisperse porous PS / DVB microspheres with a particle size of 6.24 μm were used as a template to prepare the monodisperse magnetic porous silica microspheres of this example. The specific preparation method is as follows:

[0053] (1) Weigh 5g of monodisperse porous PS / DVB microspheres with a particle size of 6.24μm, place them in a three-neck flask, add 50mL of concentrated sulfuric acid, stir well, stir mechanically at 160rpm, react for 24h, and carry out sulfonation; after the reaction, suction filter , washed three times with water and ethanol respectively, and dried in an oven at 50°C for later use.

[0054] (2) Configure Fe 2+ : Fe 3+ Iron source solution with a molar ratio of 1:2: weigh 1.645g FeCl 2 4H 2 O and 4.34 g FeCl 3 ·6H 2 Dissolve O in 20mL water to form an iron source solution. After the iron source solution is evacuated, N 2 Save it for future use. Ultrasonic disperse 0.5 g of PS / DVB microspheres sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com