Magnetically soft alloy material and preparation method, power inductor

A technology of soft magnetic alloys and alloy materials, which is applied in the fields of magnetic materials, parts of transformers/inductors, manufacturing of inductors/transformers/magnets, etc., can solve the problems of device performance deterioration, copper loss increase, magnetic core heating, etc., and achieve reduction Small loss, increased insulation, and reduced eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation method of the soft magnetic alloy material of this embodiment includes the following steps:

[0017] S1, mixing the coarse particle powder with the particle size of the Fe-based alloy material of 30 μm or more and the fine particle powder with the particle size of 15 m or less.

[0018] In this step, the Fe-based alloy material can be FeSiCr alloy, FeSiAl alloy, or FeSi alloy. It should be noted that it is necessary to mix the coarse particles and fine particles of the material. After testing, if only coarse particles are used, the loss of the prepared material will be reduced after the subsequent treatment, but the reduction is not obvious, and it is difficult to significantly improve . However, if only fine particles are used, after the subsequent treatment, the loss of the prepared material is greatly reduced, but it will also cause a serious decrease in magnetic permeability, which is difficult to have practical application value. In this step, a combin...

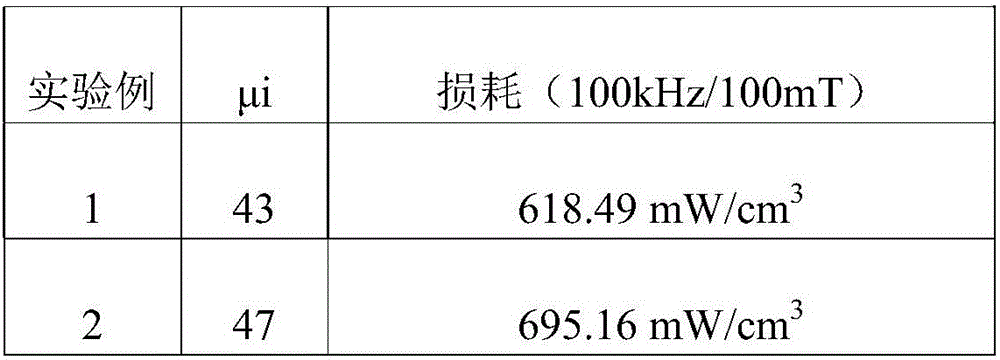

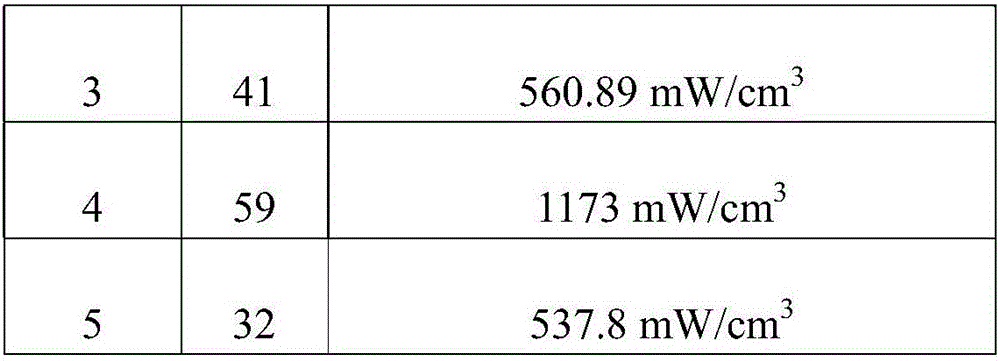

experiment example 1

[0034] Select coarse FeSiCr powder with a particle size of 30μm or more and fine FeSiCr powder with a particle size of 15μm; first, mix the two FeSiCr powders at the ratio of coarse particle = 15wt% and coarse particle = 85wt%. The FeSiCr powder was baked in an oven at 120°C for 60 minutes, while heating the stirring tank to 120°C, put the baked powder into the stirring tank to start stirring, and add aluminum dihydrogen tripolyphosphate with a concentration of 1% In the solution, after stirring for 10 minutes, the stirring tank is heated to 160° C. and then stirred for 3 hours to complete the reaction. After the reaction is completed, the powder is dried. The dried powder is mixed with pure water, 0.2wt% PVA, 0.05wt% silica aqueous solution, dispersant, and defoamer to make slurry, and then pumped to the spray tower by a peristaltic pump and sprayed at 150℃ by a centrifugal spray pan The secondary granular powder is formed during drying. The powder is pressed into a magnetic ...

experiment example 2

[0037] The preparation process of the soft magnetic alloy material is the same as that of Experimental Example 1. The difference is: when the particles are mixed, the ratio of the coarse particle powder and the fine particle powder is adjusted. The adjusted ratio is: coarse particles=18wt%, fine particles=82wt %.

[0038] Similarly, the soft magnetic alloy material prepared in this experimental example was tested, and the test results are shown in the following table.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com