Method for determining acrylic acid content in carbomer

A technology of acrylic acid and carbomer, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of unsatisfactory sensitivity and separation, cumbersome operation, and affecting measurement results, so as to prevent potential harm to health and sensitivity With the effect of high precision and overcoming cumbersome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] S1. Preparation of working standard solution:

[0031] Take acrylic acid (analytical pure), put it in a 10mL stoppered colorimetric tube, dilute to the mark with methanol, mix well, put it in a 10mL stoppered centrifuge tube, centrifuge at 5000r / min for 3min, take the supernatant with 0.22 The μm organic filter membrane is filtered, and the filtrate is used as a standard solution, and the concentration of the working standard solution is shown in Table 1:

[0032] Table 1:

[0033] Standard solution series 1# 2# 3# 4# 5# 6# Acrylic acid (μg / mL) 10 2 1 0.4 0.2 0.1

[0034] S2, sample processing:

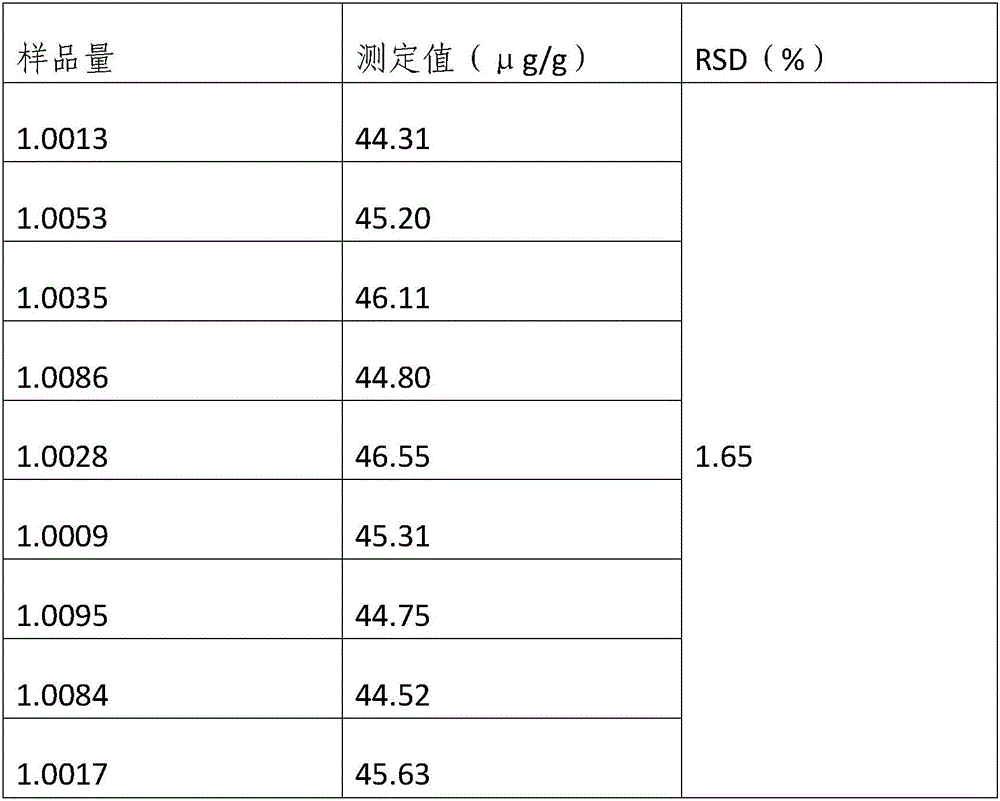

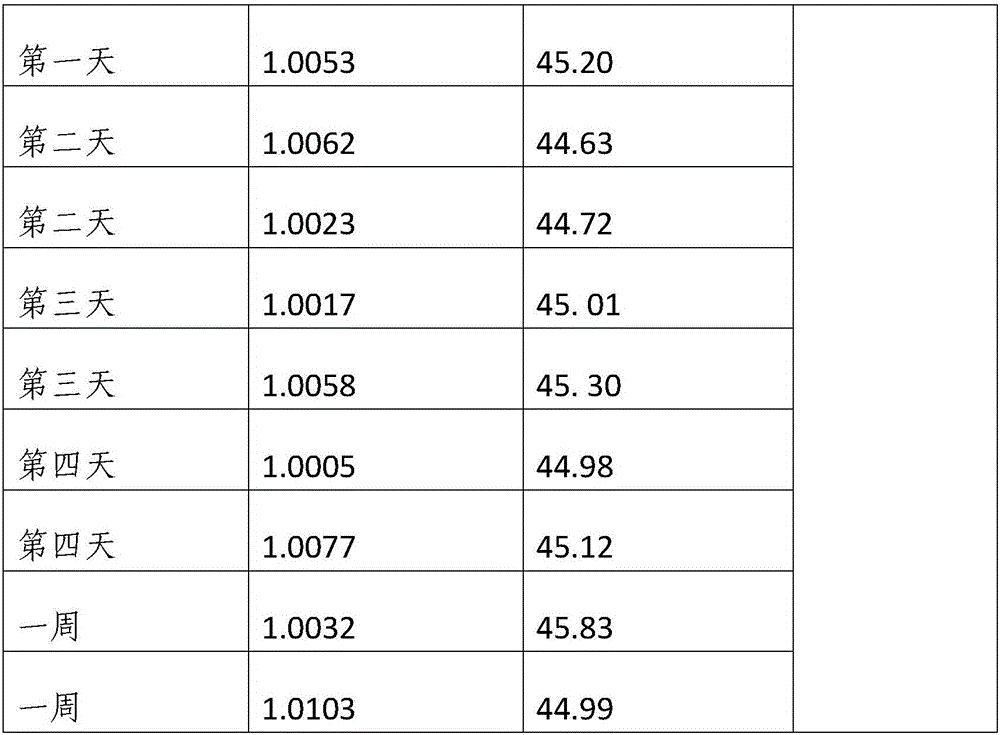

[0035] Weigh 1.0g sample, place it in a microwave extraction tube, add 15mL N,N-dimethylformamide, place the microwave extraction tube in a microwave extraction apparatus, extract at 130°C for 20min, centrifuge, and take the The clear liquid was filtered with a 0.22 μm organic filter membrane, and the filtrate was obtained as the sample solution...

Embodiment 2

[0061] The difference from Example 1 is that on the basis of "sample treatment" and "detection method", the working standard solution series and sample solution of acrylic acid are determined;

[0062] The differences are as follows:

[0063] Sample treatment: Weigh 1.0g sample, place it in a microwave extraction tube, add 15mL tetrahydrofuran, place the microwave extraction tube in a microwave extraction apparatus, extract at 120°C for 20min, centrifuge, take the supernatant and wash it with 0.22μm Filter with an organic membrane to obtain the filtrate as the sample solution;

[0064] Detection method: chromatographic column: SFC capillary column; stationary phase: silica gel; column temperature: 36°C; injection volume: 20μL; mobile phase: N2O; detection wavelength: 290nm; constant pressure: 71.7×10 6Pa; Split ratio: 10:1; Detection point: FID, 250°C; Gas supply: nitrogen;

[0065] The test results are as follows:

[0066] Linear regression equation: y=83.57x+1.43, the cor...

Embodiment 3

[0077] On the basis of the difference from Example 1 in "sample treatment" and "detection method", the working standard solution series and sample solution of acrylic acid are measured;

[0078] The differences are as follows:

[0079] Sample treatment: Weigh 1.0g sample, place it in a microwave extraction tube, add 15mL cyclohexane, place the microwave extraction tube in a microwave extraction apparatus, extract at 140°C for 15min, centrifuge, and take the supernatant for use Filter through a 0.22 μm organic filter membrane to obtain the filtrate as the sample solution;

[0080] Detection method: chromatographic column: SFC capillary column; stationary phase: silica gel; column temperature: 38°C; injection volume: 30μL; mobile phase: N2O; detection wavelength: 320nm; constant pressure: 71.7×10 6 Pa; Split ratio: 10:1; Detection point: FID, 250°C; Gas supply: nitrogen;

[0081] The test results are as follows:

[0082] Linear regression equation: y=85.12x-0.98, the correlat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com