Clip connecting edge and connecting reinforcement

A technology for connecting edges and reinforcements, applied in the direction of connecting members, thin plate connections, and slender elements, etc., can solve the problems of inconvenient recycling, difficult product disassembly, and many processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The technical solutions and other beneficial effects of the present invention will be more apparent through the detailed description of specific embodiments of the present invention in conjunction with the accompanying drawings. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

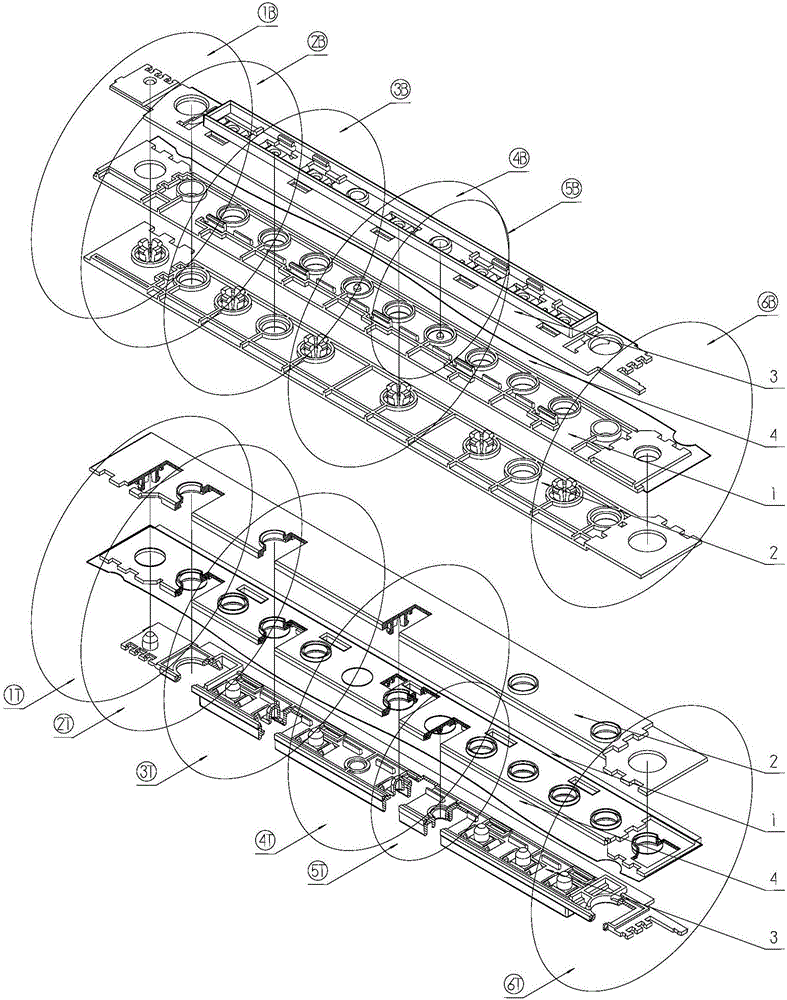

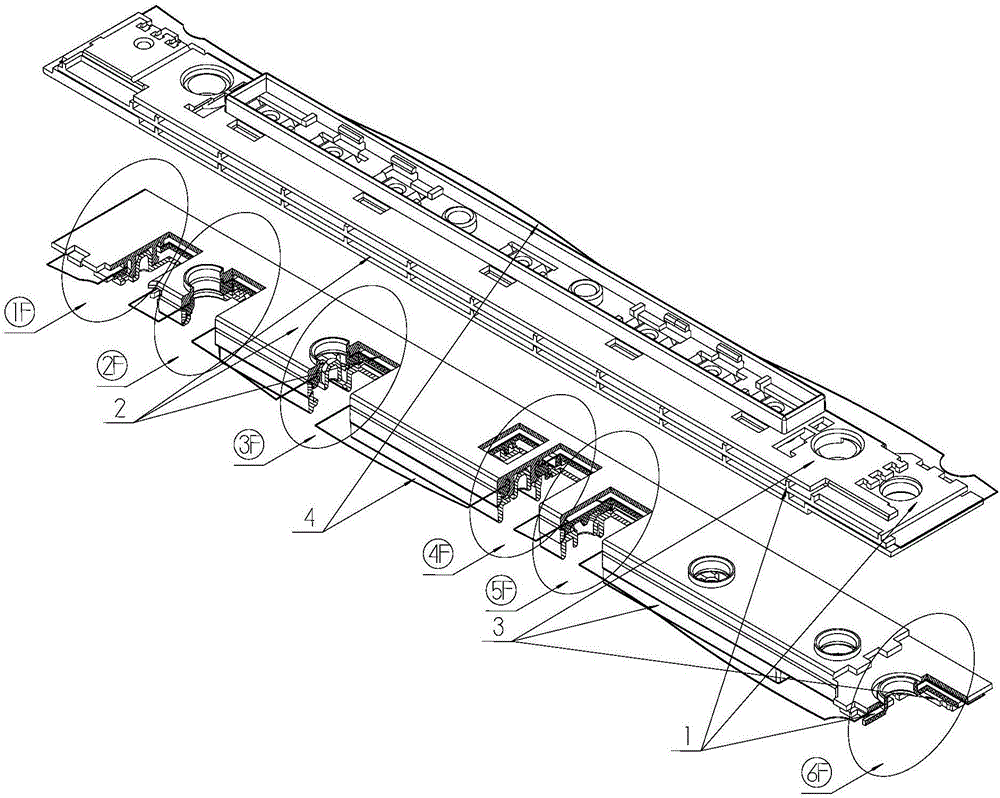

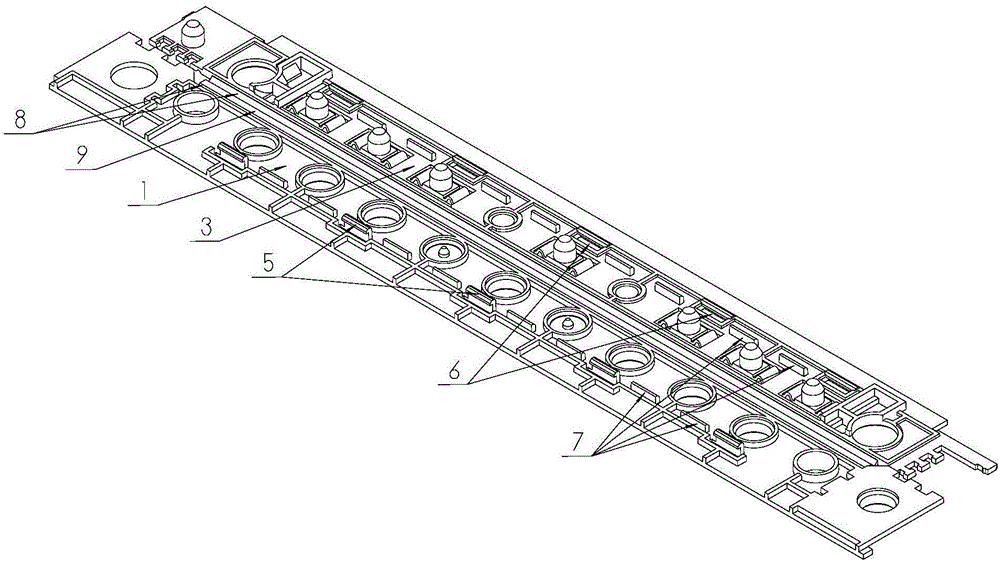

[0088] The invention provides a plastic connecting edge for clamping a perforated sheet, including 0°, 90°, 180°, T-shaped and cross connecting edges, which respectively include one, two at 90°, two at 180°, three A T-shaped and four cross-shaped clip connection units; such as Figure 1-2 As shown, the clip connection unit is used as the basic structure and functional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com