Method of utilizing waste liquid and waste residue of corn pulping to prepare fertilizer

A technology of pulping waste liquid and waste residue, which is applied in the direction of pulp beating/refinement method, application, fertilization device, etc., can solve the problems of long composting time, unfavorable nutrient preservation and utilization, etc., so as to improve fertility and solve waste liquid Pollution problems, the effect of increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

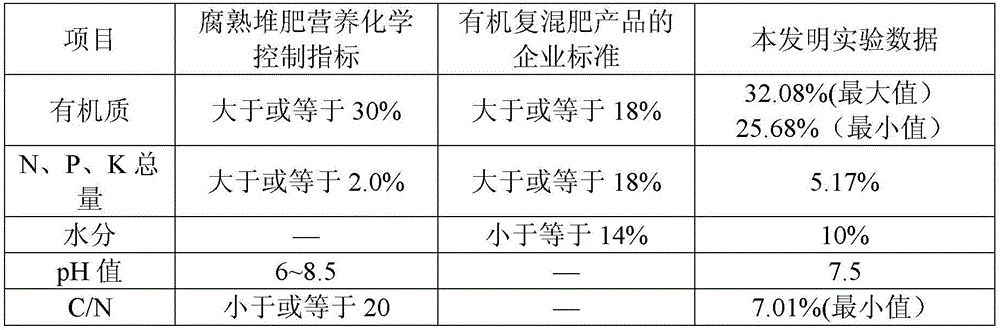

Examples

specific Embodiment approach 1

[0029] Specific embodiment one: the present embodiment utilizes the method for making fertilizer from corn pulping waste liquor and residue, comprising the following steps:

[0030] 1. Send the corn stalks into the pulverizer and crush them until the particle size is 1-2cm. First, use the centrifugal fan to send the crushed straws to the high-speed vibrating screen to make the materials in a suspended or semi-suspended state, and then use the cyclone separator to make the skin and Separation of pith to obtain corn stalk husk and waste residue;

[0031] 2. Under normal pressure, the corn stalks are soaked in the dipping solution, and after dipping, the low-concentration waste liquid is extruded through an extruder to collect the low-concentration waste liquid;

[0032] 3. Grind the impregnated corn stalk husk raw material with a double-roller mill, and the slurry separated by the double-roller mill will be sent to a high-consistency refiner for refining. After refining, it will...

specific Embodiment approach 2

[0035] Embodiment 2: This embodiment differs from Embodiment 1 in that: the corn stalk husk raw material obtained in Step 1 is pretreated first, and then subjected to the next step of dipping treatment. The specific method of the pretreatment is as follows: washing the corn stalk husk raw material with water at 50-60° C., steaming it under normal pressure for 20-30 minutes, and finally feeding it into a screw extrusion deflaking machine for extruding and deflaking. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the impregnating liquid described in step two is KOH, (NH 4 ) 2 SO 3 One or a mixture of two, where the immersion liquid is a mixed liquid when KOH and (NH 4 ) 2 SO 3 The volume ratio is 1:1. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com