Method for improving permeability and clarity of double-faced penetrated print of real silk fabric

A silk fabric, double-sided technology, applied in the field of fine chemicals, can solve problems such as difficult to achieve front and back penetration printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

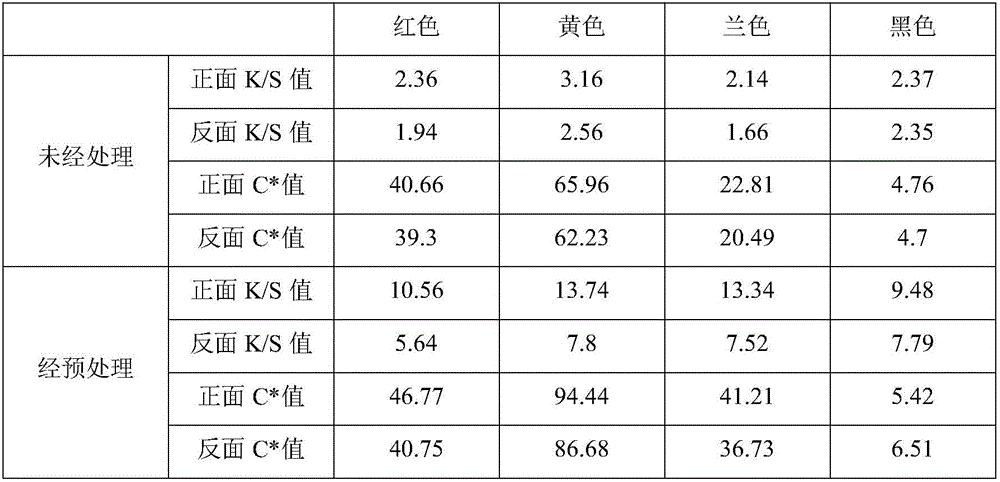

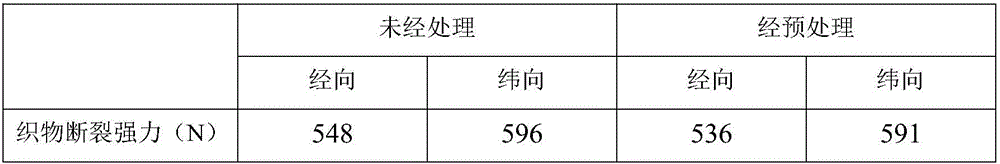

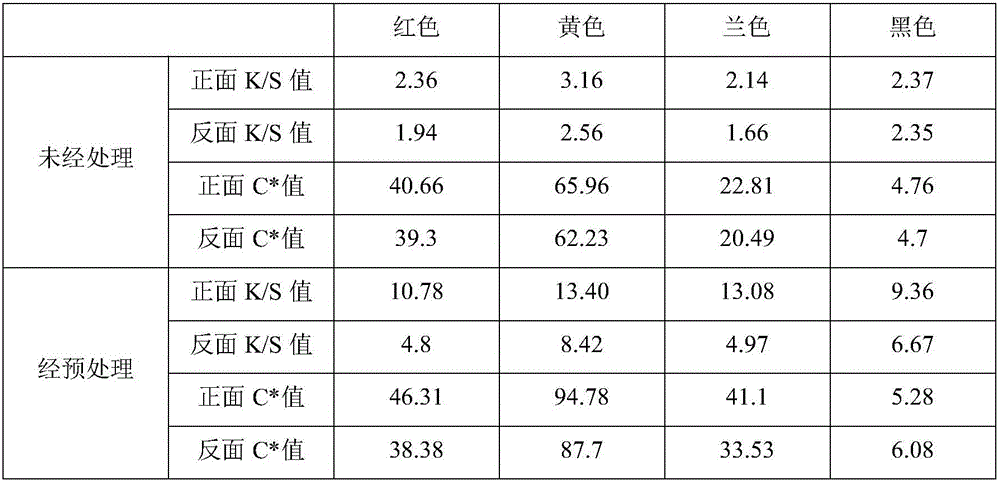

Examples

Embodiment 1

[0024] (1) Preparation of anionic nanoporous alumina dispersion: Dissolve 10% sodium polyacrylate and 1% polydimethylsiloxane into deionized water, add 30% nanoporous alumina and mix evenly, carry out with a sand mill Grinding and dispersing to prepare nanoporous alumina with an average particle size of <200nm.

[0025] (2) Preparation of pretreatment liquid: 2% anionic nanoporous alumina dispersion, 1% sodium alginate, 12% glycerol, 1% sodium carbonate, 1% ethanolamide, 0.5% 5-chloro-2-methyl -1-isothiazolin-3-one, the rest is water.

[0026] (3) Padding and drying treatment: immerse the fabric in the pretreatment solution for 5 minutes to ensure that the fabric is fully soaked, then perform one dipping and one rolling treatment, the excess rate is kept at 70%, and then dry at 60°C after padding Dry processing.

[0027] (4) Inkjet printing: use reactive dye ink to print the pretreated silk.

[0028] (5) Steaming for color fixation: place the printed fabric in a preheated s...

Embodiment 2

[0038] (1) Preparation of anionic nanoporous silica dispersion: Dissolve 20% sodium sulfonate and 0.5% amyl alcohol into deionized water, add 30% nanoporous silica and mix evenly, grind and disperse with a sand mill to prepare Nanoporous silica with an average particle size <200nm.

[0039] (2) Preparation of pretreatment liquid: 4% anionic nanoporous silica dispersion, 1% CMC, 6% urea, 10% diethylene glycol, 1% sodium bicarbonate, 1% polyethylene oxide, 0.5% 2-methyl -1-isothiazolin-3-one, the rest is water.

[0040] (3) Padding and drying treatment: immerse the fabric in the pretreatment solution for 5 minutes to ensure that the fabric is fully soaked, then perform one dipping and one rolling treatment, and the excess rate is kept at about 80%. Drying process.

[0041] (4) Inkjet printing: use reactive dye ink to print the pretreated silk.

[0042] (5) Color fixation by steaming: place the printed fabric in a preheated steamer (steaming environment: 102° C., 78% RH), and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com