14.5mm-thickness dedicated automobile spoke steel uniform in property and manufacturing method and application of spoke steel

A manufacturing method and technology of automobile wheels, which are applied in metal processing equipment and other directions, can solve the problems of large difference in anisotropic performance and short fatigue life of automobile spokes, and achieve excellent mechanical properties, uniform structure characteristics and morphology, and ensure fatigue life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

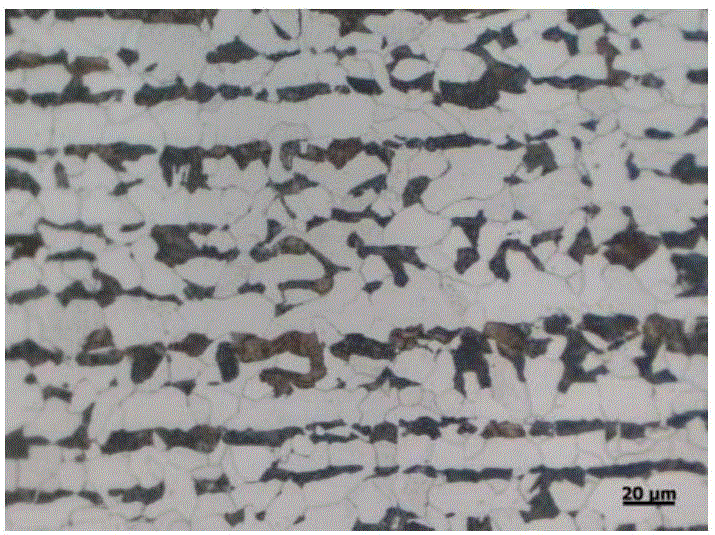

Image

Examples

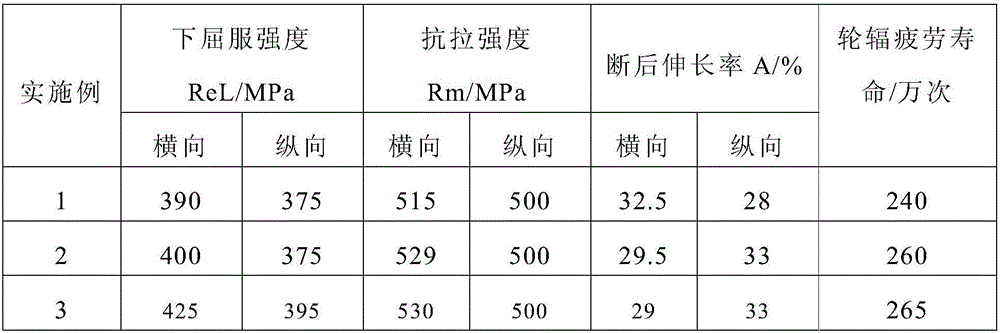

Embodiment 1

[0023] A 14.5mm-thick special-purpose automobile spoke steel with uniform isotropic properties, the chemical composition of which is: C: 0.16%, Si: 0.30%, Mn: 1.50%, P: 0.014%, S: 0.011%, al t : 0.05%, Ti: 0.02%, O: 0.0022%, and N: 0.003%, and the balance is Fe and unavoidable impurities.

[0024] The method for manufacturing the above-mentioned 14.5mm thick special-purpose automobile spoke steel with uniform anisotropic properties includes molten iron desulfurization pretreatment, converter smelting, LF furnace refining, slab continuous casting, hot rolling, cooling and heat treatment processes, the hot rolling process, Two-stage rolling of rough rolling and finish rolling is adopted, and the ratio of the cross rolling pass to the longitudinal rolling pass in the rough rolling stage is 1:3, among which, there are 8 rough rolling passes, the starting temperature of rough rolling is 1200°C, and the final rolling temperature is 1200°C. 1075°C, 6 passes of finishing rolling, the...

Embodiment 2

[0027] A 14.5mm thick special-purpose automobile spoke steel with uniform isotropic properties, its chemical composition is: C: 0.14%, Si: 0.25%, Mn: 1.35%, P: 0.012%, S: 0.019%, Al t : 0.04%, Ti: 0.01%, O: 0.0021%, and N: 0.0028%, and the balance is Fe and unavoidable impurities.

[0028] The method for manufacturing the above-mentioned 14.5mm thick special-purpose automobile spoke steel with uniform anisotropic properties includes molten iron desulfurization pretreatment, converter smelting, LF furnace refining, slab continuous casting, hot rolling, cooling and heat treatment processes, the hot rolling process, Two-stage rolling of rough rolling and finish rolling is adopted, and the ratio of the cross rolling pass to the longitudinal rolling pass in the rough rolling stage is 1:4.5, among which, there are 11 rough rolling passes, the rough rolling start temperature is 1150°C, and the finish rolling temperature is 1150°C. 1050°C, 6 passes of finishing rolling, the starting ...

Embodiment 3

[0031] A 14.5mm-thick special-purpose automobile spoke steel with uniform isotropic properties, the chemical composition of which is: C: 0.15%, Si: 0.27%, Mn: 1.40%, P: 0.010%, S: 0.012%, Al t : 0.035%, Ti: 0.015%, O: 0.0019%, and N: 0.0025%, and the balance is Fe and unavoidable impurities.

[0032] The method for manufacturing the above-mentioned 14.5mm thick special-purpose automobile spoke steel with uniform anisotropic properties includes molten iron desulfurization pretreatment, converter smelting, LF furnace refining, slab continuous casting, hot rolling, cooling and heat treatment processes, the hot rolling process, Two-stage rolling of rough rolling and finish rolling is adopted, and the ratio of cross-rolling passes to longitudinal rolling passes in the rough-rolling stage is 1:6, of which there are 7 rough-rolling passes, the rough-rolling start temperature is 1250°C, and the finish-rolling temperature is 1:6. 1100°C, 6 passes of finishing rolling, the starting tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com