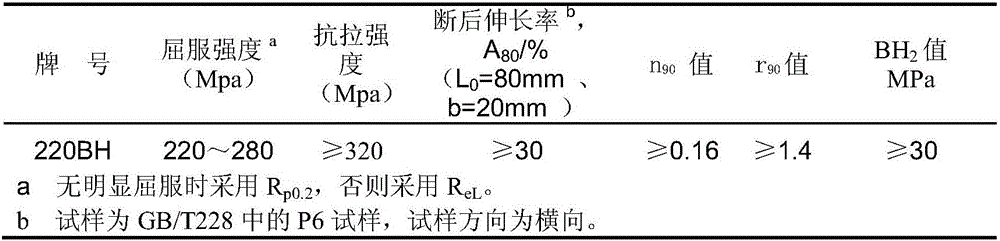

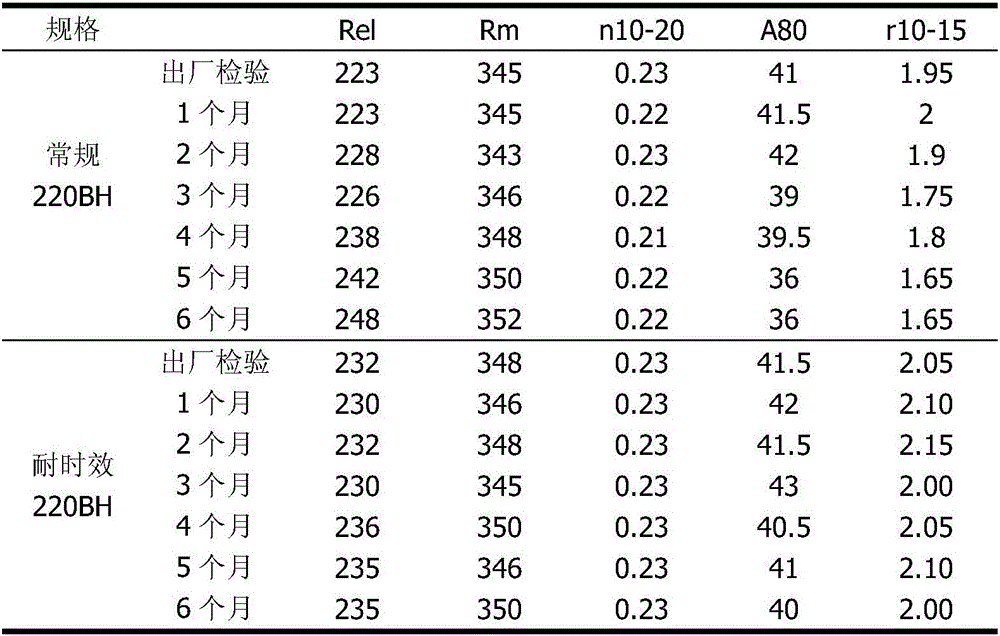

Ageing-resistant cold-rolled bake-hardening steel 220 BH and production method thereof

A bake-hardening and aging-resistant technology, which is applied in the field of aging-resistant cold-rolled bake-hardening steel, can solve problems such as poor aging resistance, meet good application requirements, improve aging resistance, and expand the application ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In this embodiment, the aging-resistant cold-rolled bake-hardening steel 220BH includes the following components in terms of mass percentage:

[0018] C: 0.001%~0.003%, Si: 0.02%, Mn: 0.50%, P: 0.060%, S: 0.008%, Als: 0.025%, Nb: 0.005%~0.030%, N: 0.0022%, Mo: 0.01~ 0.08%, the balance is iron and unavoidable impurities.

[0019] In this embodiment, the production method of aging-resistant cold-rolled bake-hardening steel 220BH is as follows:

[0020] 1) It is smelted according to the method of ultra-low carbon steel and poured into billets;

[0021] 2) Place the billet in a walking heating furnace and heat it at a heating temperature of 1200°C; after the billet comes out of the furnace, it is descaled with high-pressure water and then rolled in a rough rolling mill; Rolling by rolling mill, final rolling temperature 900°C; coiling after laminar cooling, coiling temperature 720°C; total reduction ratio of cold continuous rolling 75%; continuous annealing, heating / holdi...

Embodiment 2

[0023] In this embodiment, the aging-resistant cold-rolled bake-hardening steel 220BH includes the following components in terms of mass percentage:

[0024] C: 0.001% to 0.003%, Si: 0.02%, Mn: 0.55%, P: 0.045%, S: 0.010%, Als: 0.030%, Nb: 0.005% to 0.030%, N: 0.0024, Mo: 0.01 to 0.08 %, the balance is iron and unavoidable impurities.

[0025] In this embodiment, the production method of aging-resistant cold-rolled bake-hardening steel 220BH is as follows:

[0026] 1) It is smelted according to the method of ultra-low carbon steel and poured into billets;

[0027] 2) Place the cast slab in a walking heating furnace and heat it at a heating temperature of 1210°C; after the cast slab is released from the furnace, it is descaled by high-pressure water and then rolled in a rough rolling mill; Rolling by rolling mill, final rolling temperature 900°C; coiling after laminar cooling, coiling temperature 720°C; total reduction ratio of cold continuous rolling 70%; continuous annealin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com