Wine distilling equipment

A kind of wine steaming equipment and wine steaming technology, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of affecting the quality of wine and mixing in, and achieve the effects of improving the quality of wine, reducing the temperature of wine out, and increasing the contact area of gas and liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

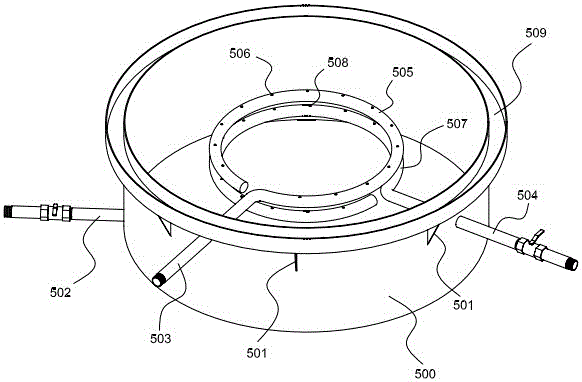

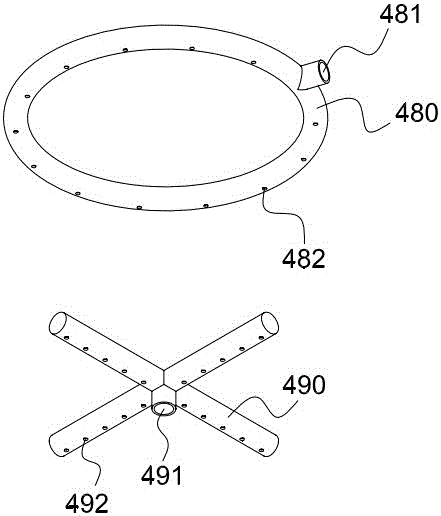

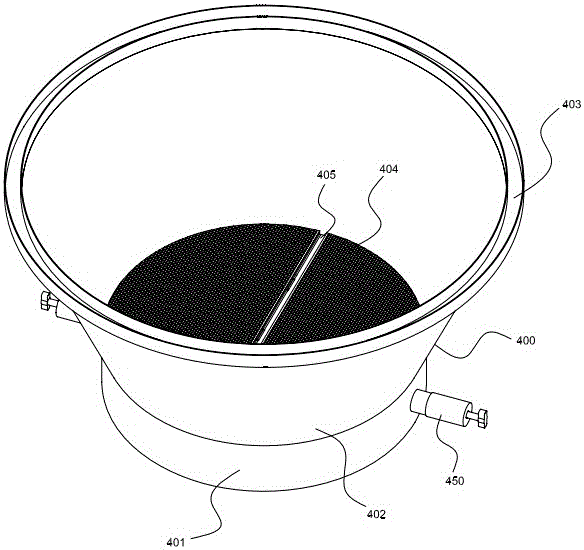

[0029] Such as figure 1 , image 3 , Figure 4 , Figure 7 As shown, the present embodiment includes a bottom pot 500, a retort barrel 400, a distillation cover 300 that covers the retort barrel 400, a wine steam pipe 200 that is connected with the distillation cover 300 and guides the wine vapor into the condenser 100 from the retort barrel 400, and The wine vapor pipe 200 is connected to the condenser 100 that condenses the wine vapor introduced by the wine vapor pipe 200 , and a blower and an air guide pipe for blowing air into the bottom pot 500 .

[0030] Such as figure 1 As shown, the bottom pot 500 is in the shape of a cylindrical barrel, and the upper end of the bottom pot 500 is provided with a water tank 509 for water-tight connection with the retort barrel 400 . When steaming wine, the lower end of the retort barrel 400 is inserted into the water tank 509, and clear water is poured into the water tank 509, thereby realizing the sealing between the retort barrel ...

Embodiment 2

[0039] refer to figure 1 , image 3 , Figure 4 , Figure 8 As shown, the present embodiment includes a bottom pot 500, a retort barrel 400, a distillation cover 300 that covers the retort barrel 400, a wine steam pipe 200 that is connected with the distillation cover 300 and guides the wine vapor into the condenser 100 from the retort barrel 400, and The wine vapor pipe 200 is connected to the condenser 100 that condenses the wine vapor introduced by the wine vapor pipe 200 , and a blower, an air guide pipe and an air guide circuit pipe for blowing air into the bottom pot 500 .

[0040] Refer to the structure of the bottom pot 500, steamer 400, blower and air duct figure 1 , image 3 , Figure 4 Shown and written description of Example 1.

[0041] Such as Figure 8 As shown, a water jacket 303 is provided above the distillation cover 300 of this embodiment, a water inlet 302 is provided below the water jacket 303 , a water outlet 304 is provided above, and the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com