Method for preparing pantograph carbon slide strip material from graphene oxide

A technology of pantograph carbon and graphene, which is applied in the field of preparation of pantograph carbon slider materials using graphene oxide, which can solve the problem that ordinary carbon materials cannot fully meet the physical and chemical indicators of carbon sliders and the production cycle of carbon sliders Long, increased manufacturing costs and other issues, to achieve good electrical conductivity, short production cycle, improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

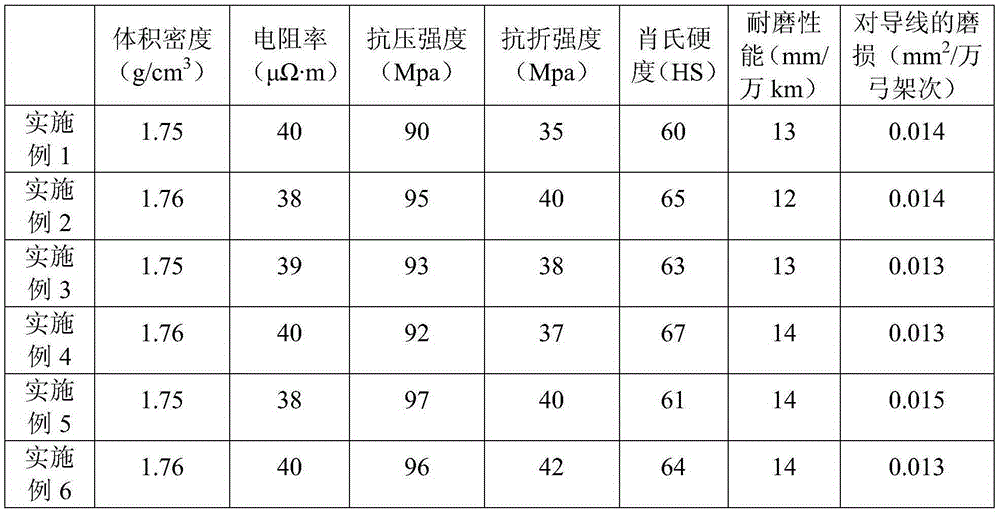

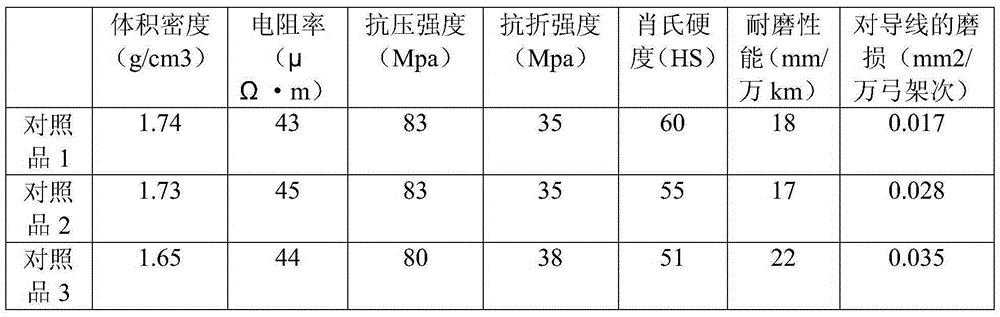

Examples

Embodiment 1

[0044] (1) Prepare the aggregates for preparing the pantograph carbon slider according to weight percentage: 3% graphene oxide, 10% semi-reinforcing carbon black, 6% graphite powder, and 71% pitch coke.

[0045] The weight ratio of aggregate to medium-temperature coal tar pitch is 74:26, the softening point of medium-temperature coal tar pitch is 85°C, and the coking value is 58%. The tensile modulus of graphene oxide is 1.01TPa, and the ultimate strength is 116Gpa. Semi-reinforced carbon The black particle size is 0.07mm, the resistivity is 0.6μΩ·m, and the true density of pitch coke is 2.10g / cm 3 , the ash content is 0.45%, the volatile matter is 0.75%, and the particle size of graphite powder is 0.5mm. Among them, the pitch coke is crushed, pulverized, and sieved. The percentage is 55%, the particle size ≤ 0.15mm accounts for 45% of the weight percentage of the total pitch coke, and the prepared aggregate particle size is 0.15mm-2mm.

[0046] (2) Put the aggregate prepared...

Embodiment 2

[0052] (1) Prepare the aggregates for preparing the pantograph carbon slider according to weight percentage: 3% graphene oxide, 10% semi-reinforcing carbon black, 7% graphite powder, and 80% pitch coke.

[0053] The weight ratio of aggregate to medium-temperature coal tar pitch is 73:27, the softening point of medium-temperature coal tar pitch is 87°C, and the coking value is 58%. The tensile modulus of graphene oxide is 1.01TPa, and the ultimate strength is 116Gpa. Semi-reinforced carbon The black particle size is 0.08mm, the resistivity is 0.4μΩ·m, and the true density of pitch coke is 2.50g / cm 3 , the ash content is 0.45%, the volatile matter is 0.75%, and the particle size of graphite powder is 0.5mm. Among them, the pitch coke is crushed, pulverized, and sieved. The percentage is 57%, the particle size ≤ 0.15mm accounts for 43% by weight of the total pitch coke, and the prepared aggregate particle size is 0.15mm-2mm.

[0054] (2) Put the aggregate prepared above into the...

Embodiment 3

[0060] (1) Prepare the aggregates for preparing the pantograph carbon slider according to weight percentage: 4% graphene oxide, 12% semi-reinforcing carbon black, 7% graphite powder, and 77% pitch coke.

[0061] The weight ratio of aggregate to medium-temperature coal tar pitch is 72:28, the softening point of medium-temperature coal tar pitch is 88°C, and the coking value is 60%. Among them, the tensile modulus of graphene oxide is 1.01TPa, and the ultimate strength is 116Gpa. Semi-reinforced carbon The black particle size is 0.09mm, the resistivity is 0.4μΩ·m, and the true density of pitch coke is 2.50g / cm 3 , the ash content is 0.45%, the volatile matter is 0.75%, and the particle size of graphite powder is 0.9mm. Among them, the pitch coke is crushed, pulverized, and sieved. The percentage is 58%, the particle size ≤ 0.15mm accounts for 42% by weight of the total pitch coke, and the prepared aggregate particle size is 0.15mm-2mm.

[0062] (2) Put the aggregate prepared ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com