Method for rapidly forming anammox granule sludge

An anammox and granular sludge technology, applied in anaerobic digestion treatment and other directions, can solve the problems of small particle size of anammox sludge, unfavorable engineering application, and long cultivation time, etc. Easy operation and shortened time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

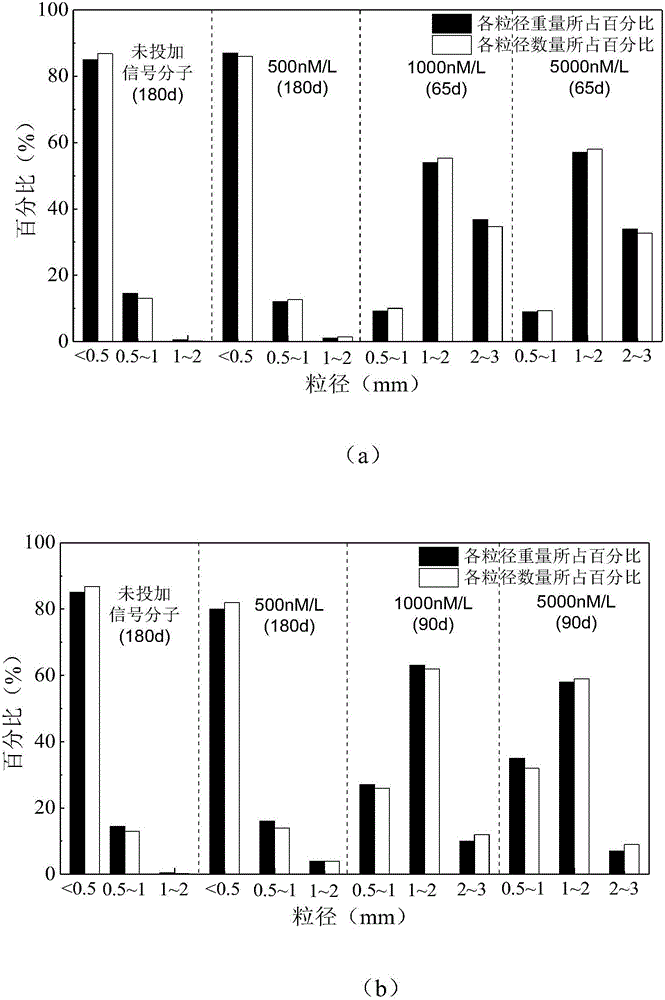

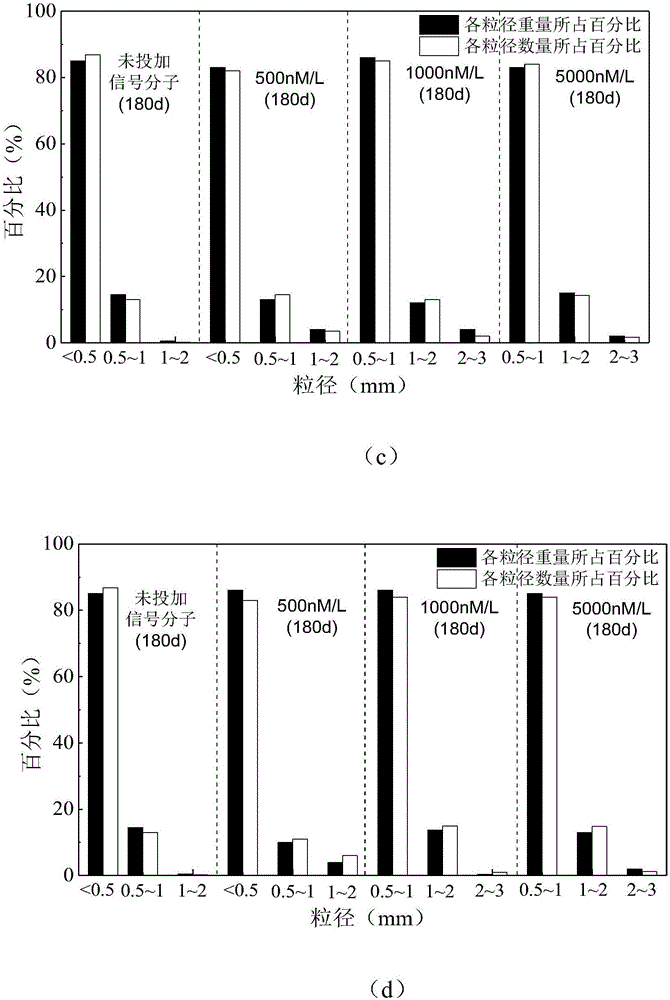

[0033] Effect of signal molecules on the formation of anammox granular sludge when anaerobic granular sludge was used as inoculum sludge

[0034] Five groups of SBR reactors were set up, namely no signal molecule group, C7-HSL group, C8-HSL group, 3OC8-HSL group, and C10-HSL group. Among them, three SBR reactors are set up in each group of adding signal molecules, and the dosing concentration of signal molecules in each reactor is set to 500nM / L, 1000nM / L and 5000nM / L respectively (three kinds of signal molecules adopt dimethyl methylene The sulfone was dissolved first, and the concentrations of the prepared four signal molecule solutions were all 20 mg / mL). Add the same amount of anaerobic granular sludge to the five groups of reactors. During the acclimation stage of anaerobic granular sludge cultivation, the concentrations of ammonia nitrogen and nitrite nitrogen in the influent nutrient solution are controlled at about 50 mg / L, and different signals are added to the reacto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com