Sea water desalinization method by waste heat recovery

A waste heat recovery and seawater technology, applied in chemical instruments and methods, seawater treatment, general water supply conservation, etc., can solve the problems of large power consumption, small operating flexibility, high investment, etc., to increase temperature, increase heat transfer speed, and save energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A seawater desalination method with waste heat recovery, comprising the following steps:

[0029] 1) Use the boiler flue gas to exchange heat with the low-pressure exhaust steam of the steam turbine, and the low-pressure exhaust steam after heat exchange is used as power steam;

[0030] 2) The power steam is passed into the heater of the multi-stage flash evaporation device to heat the raw seawater;

[0031] 3) The heated seawater sprays atomized seawater into the first-stage flash chamber through the water injector,

[0032] ① The atomized seawater evaporates rapidly under low pressure, and after the steam passes through the vapor-liquid separation device in the flash chamber, it condenses in contact with the condensing tube bundle to obtain fresh water with low salt content;

[0033] ②Atomized seawater enters the flash chamber under high-speed jetting, and small liquid droplets collide with each other and the wall of the vessel to form droplets and fall into the brin...

Embodiment 2

[0036] A seawater desalination method with waste heat recovery, comprising the following steps:

[0037] 1) Use the boiler flue gas to exchange heat with the low-pressure exhaust steam of the steam turbine, and the low-pressure exhaust steam after heat exchange is used as power steam;

[0038] 2) The power steam is passed into the heater of the multi-stage flash evaporation device to heat the raw seawater;

[0039] 3) The heated seawater sprays atomized seawater into the first-stage flash chamber through the water injector,

[0040] ① The atomized seawater evaporates rapidly under low pressure, and after the steam passes through the vapor-liquid separation device in the flash chamber, it condenses in contact with the condensing tube bundle to obtain fresh water with low salt content;

[0041] ②Atomized seawater enters the flash chamber under high-speed jetting, and small liquid droplets collide with each other and the wall of the vessel to form droplets and fall into the brin...

Embodiment 3

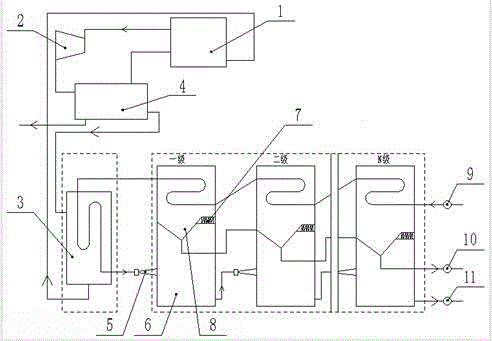

[0045] Such as figure 1 As shown, a waste heat recovery seawater desalination device includes a boiler 1 and a multi-stage flash device, and the multi-stage flash device includes a heater 3 and a multi-stage flash chamber,

[0046] The steam outlet of the boiler 1 is connected to the steam inlet of the steam turbine 2, and the flue gas outlet of the boiler 1 is connected to the flue gas inlet of the flue gas heat exchanger 4; the low-pressure exhaust steam outlet of the steam turbine 2 exchanges heat with the flue gas The steam inlet of the device 4 is connected, the steam outlet of the flue gas heat exchanger 4 is connected to the medium inlet of the heater 3, and the medium outlet of the heater 3 is connected to the water inlet of the boiler 1; the outlet pipe of the heater is connected to the first stage The flash chamber of the flash chamber is connected by a water injector 5, and the brine tank 6 of the previous flash chamber in two adjacent flash chambers is also connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com