Raw material composition and method for preparing special graphite material

A raw material composition, special graphite technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of poor bulk density, electrical resistivity, mechanical strength, etc., to improve bulk density and strength, and improve coking rate. , to avoid the effect of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

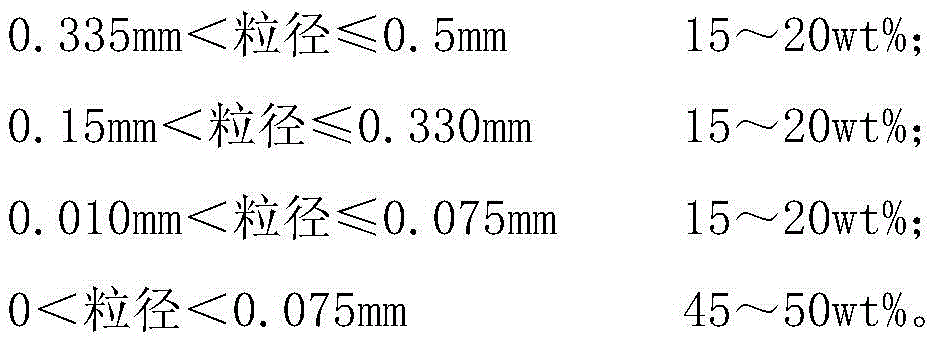

[0050] The equisquence is broken, sieved, and dosed as follows:

[0051]

[0052] The above-mentioned materials were put into a kneading pot for dry mixing. The dry mixing temperature was 150° C., and the dry mixing time was 52 minutes to obtain a dry material after dry mixing.

[0053] After the dry mixing is completed, add medium-temperature coal tar pitch into the kneading pot, and the mass percentage of dry material and medium-temperature coal tar pitch is 71%:29%. Wherein, the medium-temperature coal tar pitch is added to the dry material after dry mixing twice for kneading, the weight of the medium-temperature coal tar pitch added for the first time is 80% of the total medium-temperature coal tar pitch, and the time of kneading for the first time is 22 minutes; The weight of the medium-temperature coal tar pitch added for the second time is 20% of the total medium-temperature pitch, the time for the second kneading is 22 minutes, and the temperature for the second kne...

Embodiment 2

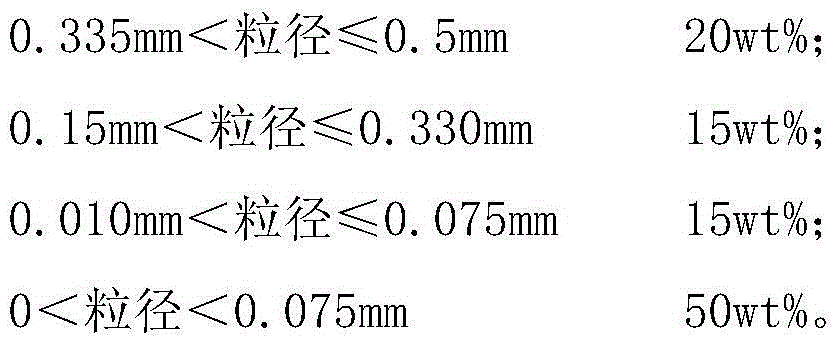

[0060] The equisquence is broken, sieved, and dosed as follows:

[0061]

[0062] The above-mentioned materials were put into a kneading pot for dry mixing. The dry mixing temperature was 140° C. and the dry mixing time was 55 minutes to obtain a dry material after dry mixing.

[0063] After the dry mixing is completed, add medium-temperature coal tar pitch into the kneading pot, and the mass percentage of dry material and medium-temperature coal tar pitch is 70:30%. Wherein, the medium-temperature coal tar pitch is added into the dry material after dry mixing twice for kneading, the weight of the medium-temperature coal tar pitch added for the first time is 75% of the total medium-temperature coal tar pitch, and the time of kneading for the first time is 20 minutes; The weight of the medium-temperature coal tar pitch added for the second time is 25% of the total medium-temperature pitch, the time for the second kneading is 20 minutes, and the temperature for the second kne...

Embodiment 3

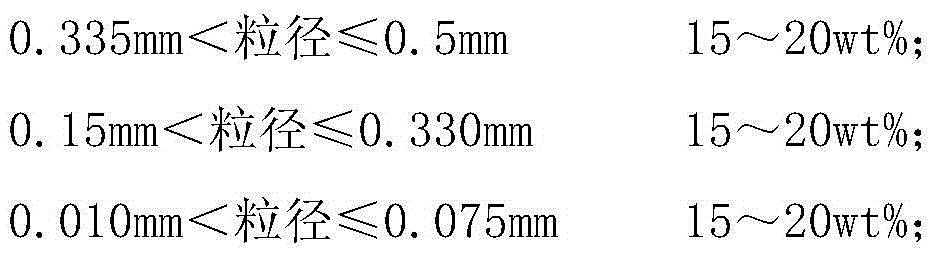

[0070] The equisquence is broken, sieved, and dosed as follows:

[0071]

[0072] The above-mentioned materials were put into a kneading pot for dry mixing. The dry mixing temperature was 160° C. and the dry mixing time was 50 minutes to obtain a dry material after dry mixing.

[0073]After the dry mixing is completed, add medium-temperature coal tar pitch into the kneading pot, and the mass percentage of dry material and medium-temperature coal tar pitch is 72%:28%. Wherein, the medium temperature coal tar pitch is added into the dry material after dry mixing in two times for kneading, the weight of the medium temperature coal tar pitch added for the first time is 85% of the total medium temperature coal tar pitch, and the time of kneading for the first time is 25 minutes; The weight of the medium-temperature coal tar pitch added for the second time is 15% of the total medium-temperature pitch, the time for the second kneading is 25 minutes, and the temperature for the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com