Temperature and humidity control device and standard curing box

A temperature and humidity control and temperature control device technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of cumbersome humidity control methods in standard breeding boxes, and achieve the effects of reducing labor intensity, realizing recycling, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

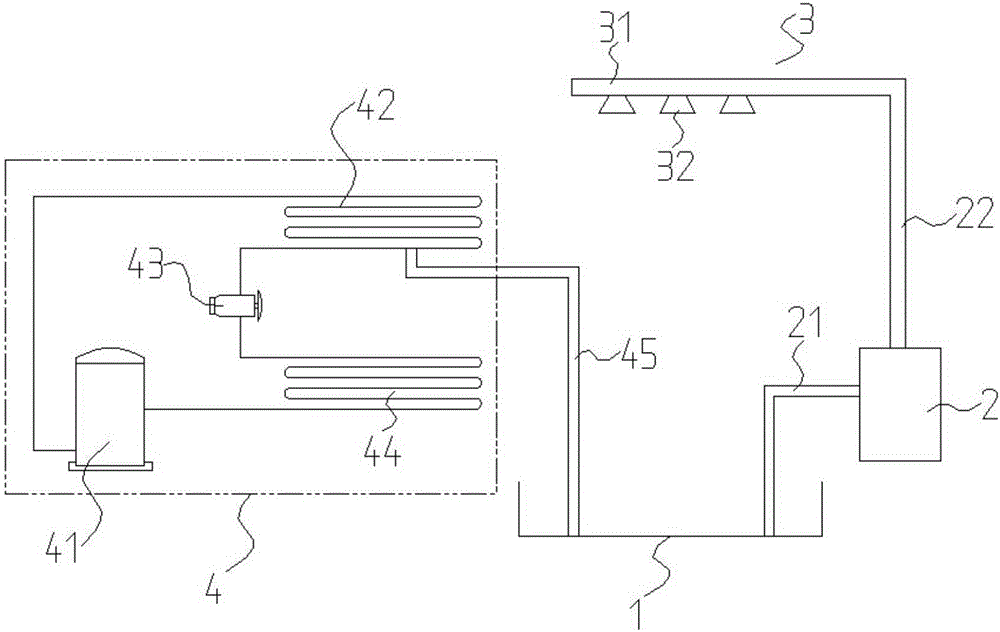

[0041] Such as figure 1 As shown, the present embodiment provides a temperature and humidity control device, including a high-pressure water pump 2, a water storage tank 1 communicated with the water pump inlet pipe 21 of the high-pressure water pump 2, and a spray nozzle connected with the water pump outlet pipe 22 of the high-pressure water pump 2. The shower device 3, the temperature control device 4 for adjusting the ambient temperature, and the power supply device 7 for providing electric energy for the high pressure water pump 2 and the temperature control device 4. Wherein, the spraying device 3 is arranged in the curing area, and the remaining curing water sprayed by the spraying device 3 flows into the reservoir 1 .

[0042] Specifically, please continue to refer to figure 1 , in this embodiment, wherein, the temperature control device 4 is provided with a drainage pipe 45 for discharging the temperature-controlled residual water, and the drainage pipe 45 is connecte...

Embodiment 2

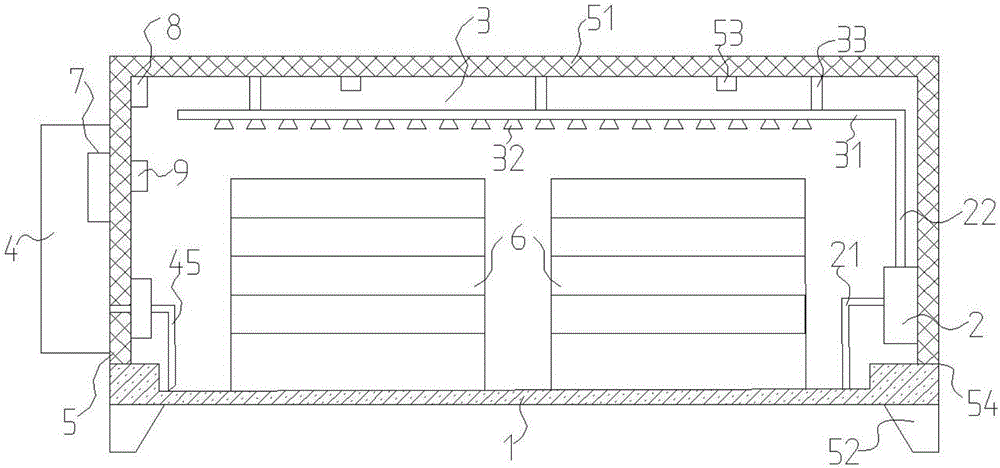

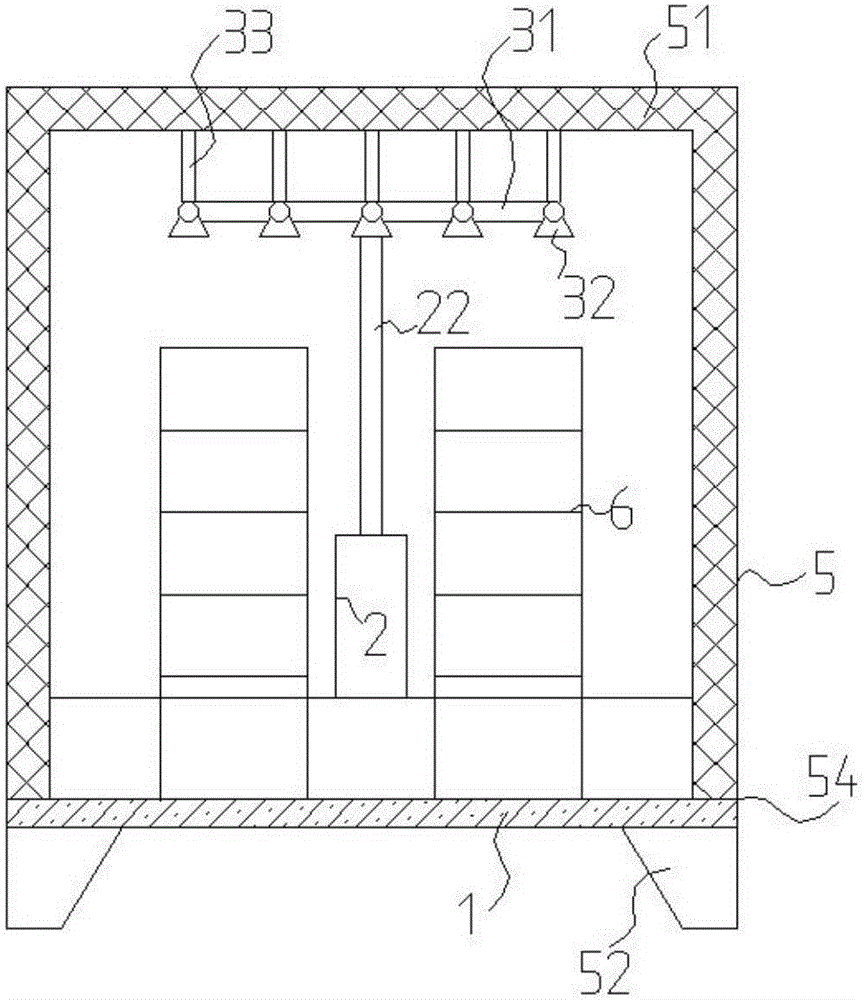

[0048] Such as Figure 2-Figure 4 As shown, the present embodiment provides a standard raising box, which includes a box body 5 and the above-mentioned temperature and humidity control device, wherein the box body 5 is a structure with an opening at the bottom, and the water reservoir 1 is arranged in the box of the standard raising box The bottom of the body 5 communicates with the inner cavity of the box body 5. The temperature control device 4 includes a compressor 41, a first heat exchanger 42 and a second heat exchanger 44 respectively communicated with the compressor 41 through medium pipelines, and Throttle device 43 between.

[0049] Specifically, in this embodiment, the high-pressure water pump 2, the spray device 3 and the first heat exchanger 42 are arranged inside the box body 5, and the compressor 41, the throttling device 43 and the second heat exchanger 44 are arranged inside the box body 5. outside, and a drain pipe 45 is provided on the first heat exchanger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com