Three-way pipe for casting and use method thereof

A technology of three-way pipe and hose, applied in the field of foundry three-way pipe and sand casting production, can solve the problems of inconvenient management, pollution, difficult to see whether the sand and gravel are effectively removed, etc., achieve effective cleaning, reduce labor intensity, guarantee The effect of working airflow intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

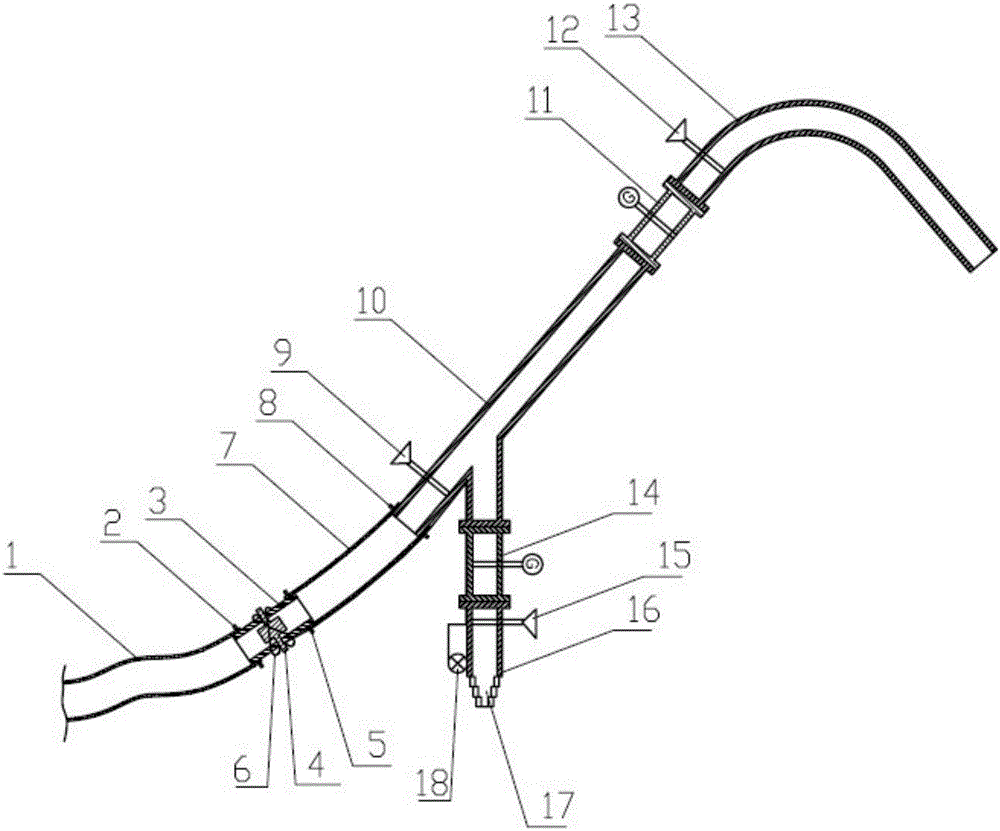

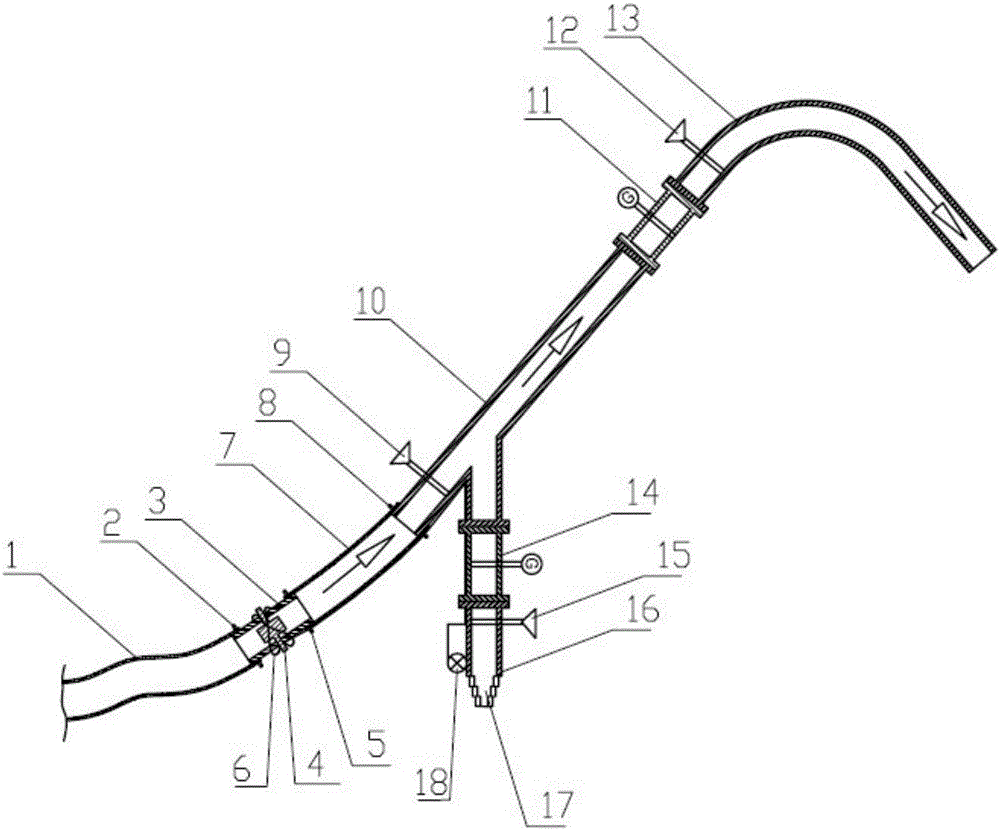

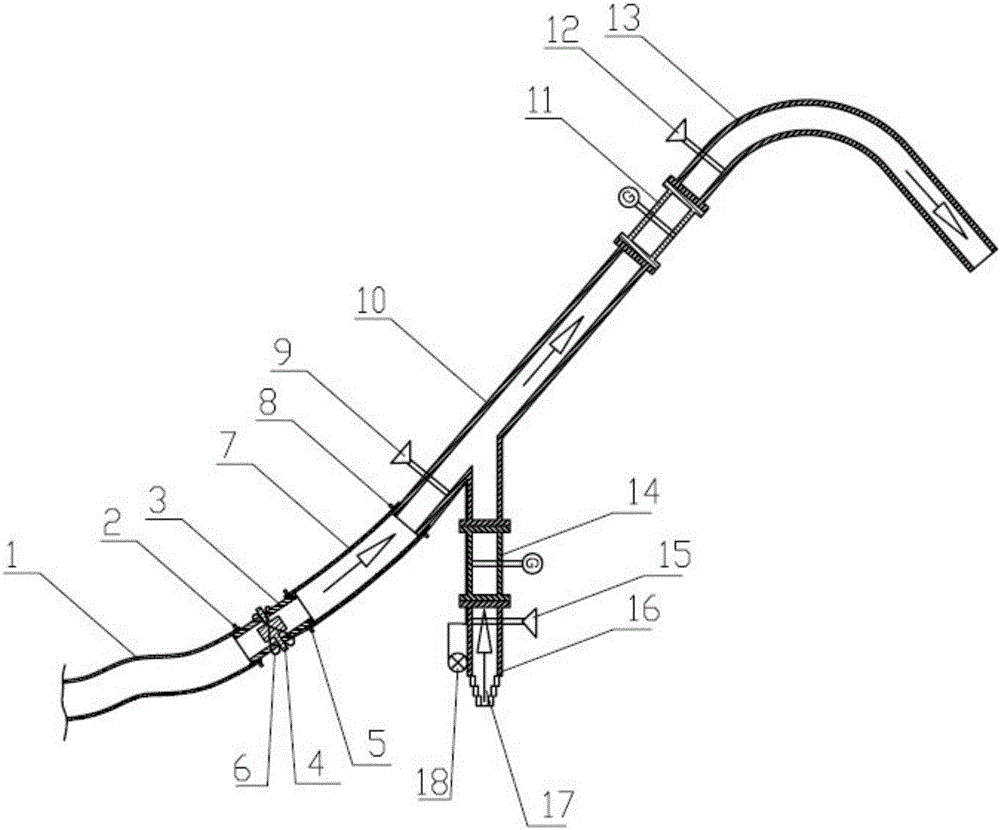

[0032] Such as Figure 1-5 Said, a kind of casting tee pipe of the present invention, comprises the inlet pipe 10 that connects and outlet pipe 13, and described inlet pipe 10 is provided with the suction pipe 16 that communicates with inlet pipe 10; One end of described inlet pipe 10 Connect the pneumatic hose 7, and the other end is connected to the air outlet pipe 13; the pneumatic hose 7 is connected to the compressed air leather pipe 1 through the glass steel pipe 3; The connection of the pipe 7, and is located at the position of 1 / 3-1 / 2 of the pipe length of the air intake pipe 10; the connection angle between the air intake pipe 10 and the suction pipe 16 is 35°-45°; the air intake pipe 10 and the pneumatic The connection of the flexible pipe 7 is provided with an air inlet pipe valve 9, and the connection of the air inlet pipe 10 and the outlet pipe 13 is provided with an outlet pipe gas flowmeter 11, and the outlet pipe 13 is provided with an outlet pipe air valve 12;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com