High-boron low-alloy high-speed steel base WC40 steel-bonded hard alloy guide and guard roller and manufacturing method thereof

A steel-bonded hard alloy and low-alloy technology is applied in the field of steel rolling guide rolls to achieve the effects of low cost, reduced manufacturing cost, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

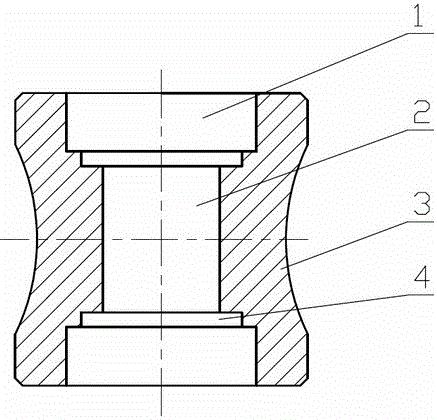

Image

Examples

Embodiment 1

[0031] The manufacturing process of the high-boron low-alloy high-speed steel-based WC40 steel-bonded hard alloy guide roller of the present invention generally includes the following steps:

[0032] (1) Guide roller material:

[0033]The mass percentage of the chemical composition of the material is C0.3%, Cr5.03%, W2.5%, Mo1.8%, V1.5%, Nb0.5%, Si0.3%, Mn0.3%, B1.4% , Cu0.30%, Ni0.80%, S≤0.02, P≤0.02, CeO20.3%, WC40%, the balance is Fe;

[0034] (2) Manufacture and processing of guide rollers:

[0035] 1) Forging the high-boron low-alloy high-speed steel-based WC40 steel-bonded hard alloy manufactured by powder metallurgy;

[0036] 2) Spheroidizing and annealing the forged high-boron low-alloy high-speed steel-based WC40 steel-bonded hard alloy to make the hardness of the steel-bonded hard alloy <HRA74;

[0037] 3) The steel-bonded cemented carbide after spheroidizing annealing is processed according to the size required by the guide roller product, and a certain amount of...

Embodiment 2

[0044] The manufacturing process of the high-boron low-alloy high-speed steel-based WC40 steel-bonded hard alloy guide roller of the present invention generally includes the following steps:

[0045] (1) Guide roller material:

[0046] The mass percentage of the chemical composition of the material is C0.6%, Cr7.0%, W3.0%, Mo3.0%, V2.5%, Nb1.0%, Si1.0%, Mn1.0%, B2.5% , Cu1.0%, Ni2.0%, S≤0.02, P≤0.02, CeO2 0.8%, WC50%, the balance is Fe;

[0047] (2) Manufacture and processing of guide rollers:

[0048] 1) Forging the high-boron low-alloy high-speed steel-based WC40 steel-bonded hard alloy manufactured by powder metallurgy;

[0049] 2) Spheroidizing and annealing the forged high-boron low-alloy high-speed steel-based WC40 steel-bonded hard alloy to make the hardness of the steel-bonded hard alloy <HRA74;

[0050] 3) The steel-bonded cemented carbide after spheroidizing annealing is processed according to the size required by the guide roller product, and a certain amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com