Metal oxyhydroxide catalyst, electrode, preparation methods of catalyst and electrode and electrochemical electrolysis unit

An oxyhydroxide and electrolysis device technology, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, electrode, etc., can solve the problem of unsatisfactory energy conversion efficiency, limiting equipment industrialization, Slow kinetics and other issues, to achieve excellent catalytic performance, abundant reserves, and reduce catalytic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation method of metal oxyhydroxide catalyst provided by the invention comprises the following steps:

[0056] Dissolving two or more metal salt precursors of 3d transition metal elements and at least one compound precursor of regulator elements in a first polar organic solvent to generate a first solution;

[0057] mixing traces of water in said first polar organic solvent to produce a second solution;

[0058] mixing the cooled first solution and the cooled second solution to form a gel within a preset time;

[0059] soaking the gel in a second polar organic solvent to remove unreacted metal salt precursors and compound precursors from the gel;

[0060] The gel is dried without annealing to produce an uncrystallized powder aerogel, which is the metal oxyhydroxide catalyst.

[0061] Wherein, the first polar organic solvent can be any organic solvent capable of dissolving the metal salt precursor and the compound precursor of the regulator element, including ...

Embodiment 1

[0072] Embodiment 1 FeCoW oxyhydroxide catalyst and preparation method thereof

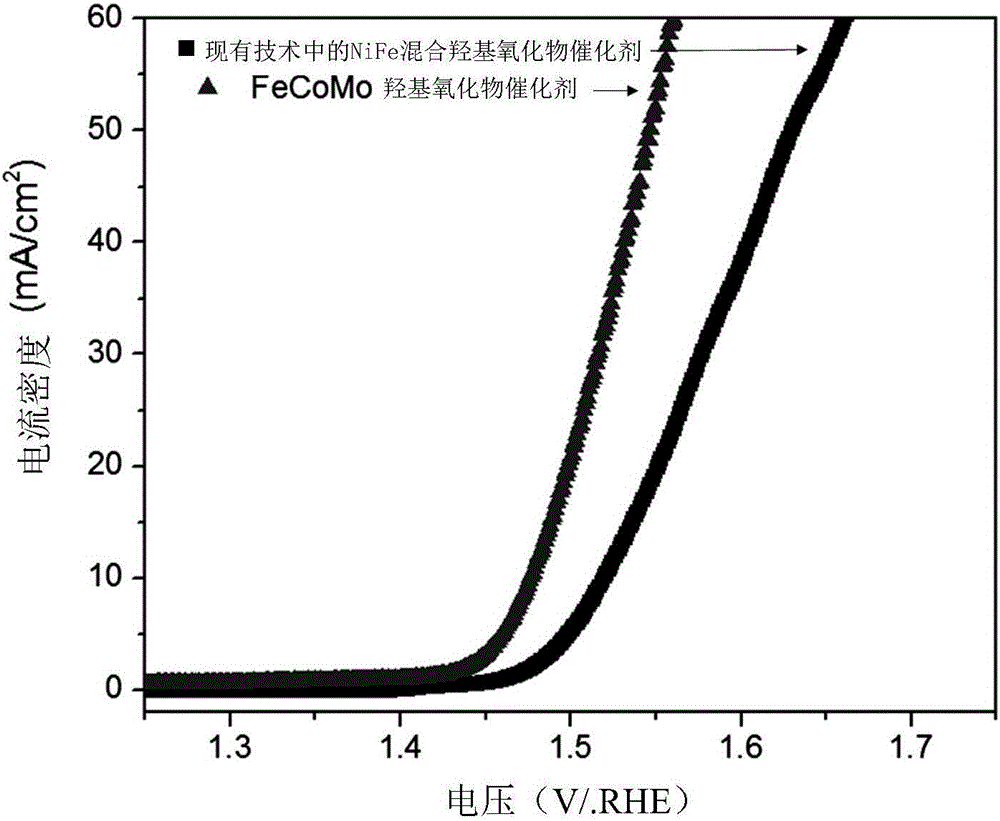

[0073] This embodiment discloses a FeCoMo oxyhydroxide catalyst, that is, the FeCoMo oxyhydroxide in the FeCoMo oxyhydroxide catalyst contains two 3d transition metal elements, Fe and Co, and Mo is used as a regulator element. The FeCoMo hydroxyhydroxide In the oxide structure, the atomic covalent radii of Fe and Co differ from Mo by more than 6%, and Fe, Co and Mo are bridged by oxygen atoms (O) or hydroxyl groups (OH), achieving a homogeneous distribution at the atomic level. And through the interaction between adjacent Fe, Co and Mo, the adsorption energy of the oxygen evolution reaction intermediate can be adjusted.

[0074] This embodiment also discloses a preparation method of a FeCoMo oxyhydroxide catalyst, which is realized by a sol-gel method at room temperature, and specifically includes the following steps:

[0075] First, the anhydrous FeCl 3 (eg 0.9mmol), CoCl 2 (eg 0.9mmol) and Mo...

Embodiment 2

[0096] Embodiment 2 FeCoMoW oxyhydroxide catalyst and its preparation

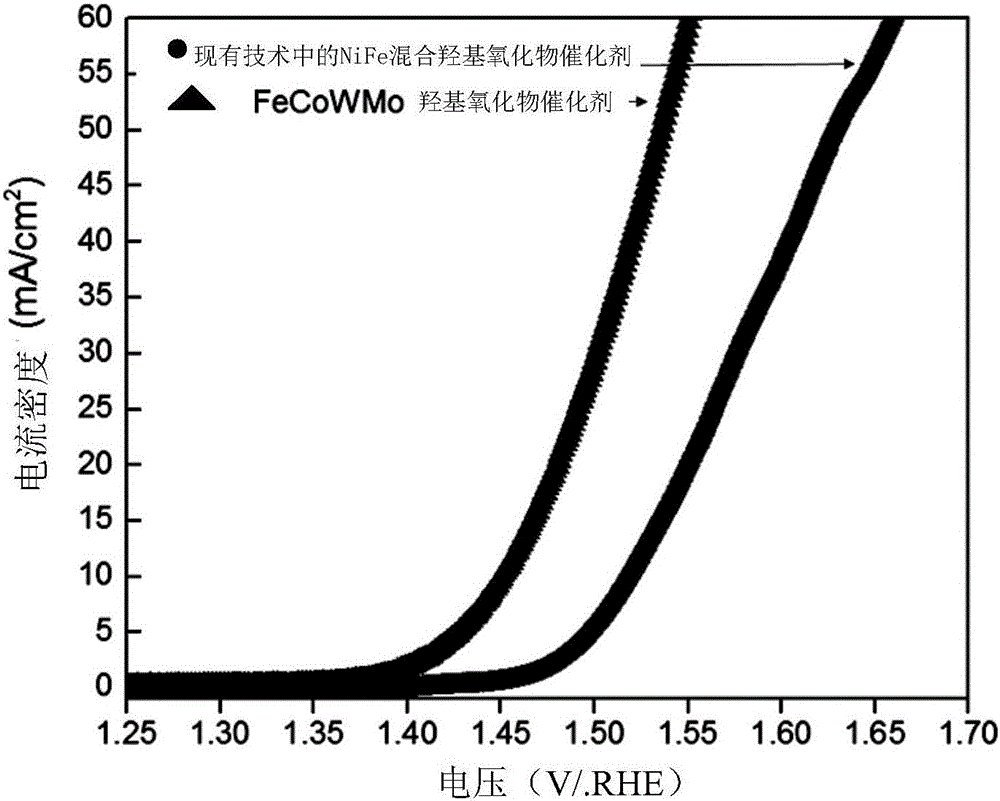

[0097] The main component of the FeCoMoW oxyhydroxide catalyst in this embodiment is FeCoMoW oxyhydroxide, which contains two 3d transition metal elements, Fe and Co, and Mo and W as regulator elements. In the structure of the FeCoMoW oxyhydroxide, Fe The atomic covalent radii of Co and Mo and W differ by more than 6%, and Fe, Co and Mo and W are bridged by oxygen atoms (O) or hydroxyl groups (OH), achieving a homogeneous distribution at the atomic level, and by phase The interaction between adjacent Fe, Co and Mo, W can adjust the adsorption energy of oxygen evolution reaction intermediates.

[0098] The preparation method of the FeCoMoW oxyhydroxide catalyst in this example is basically the same as in Example 1, where only the type and amount of the precursor and the amount of trace water added need to be changed. Specifically, anhydrous FeCl 3 (eg 0.7mmol), CoCl 2 (eg 0.7mmol), WCl 6 (eg 0.7mmol) and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com