Preparation method of shrimp-flavor green barley cookies

A biscuit and shrimp-flavored technology is applied in the field of preparation of shrimp-flavored green wheat biscuit, which can solve the problems of difficulty in guaranteeing quality and sanitation, difficult preservation and export, extensive production method, etc., and achieves the effects of delicious taste, unique texture and strong taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A preparation method of shrimp-flavored green wheat biscuits, comprising the following steps:

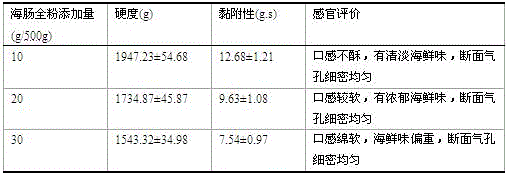

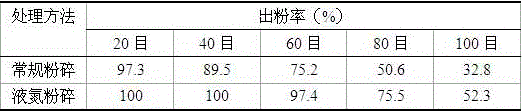

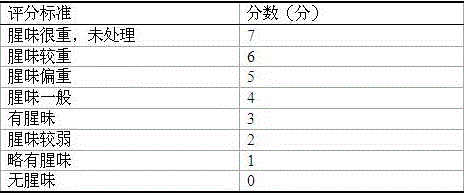

[0022] Step 1. Take fresh midge shrimp raw materials, clean the midge shrimp with fresh water, then put the washed midge shrimp in boiling water for 1 minute, put them into a meat grinder after blanching, add ice and grind for 1 minute, add The amount of ice is 1 / 5-1 / 3 of the weight of the midge shrimp, and then the twisted midge shrimp is transferred to a vacuum freeze dryer for drying; after drying, put it into a pulverizer, and add liquid nitrogen at room temperature , crushing at intervals, each crushing 1min, stop 20s, crushing 5 times for a total of 5min, the amount of nitrogen flow during crushing is 160-260mL / 100 g, crushing to obtain midge shrimp powder, set aside; use 40 mesh sieve for midge shrimp powder Sieve, collect midge and shrimp powder less than 40 mesh, and place in supercritical CO 2 In the extraction device, under the conditions of a pressure of 35MPa an...

Embodiment 1

[0027] A preparation method of shrimp-flavored green wheat biscuits, comprising the following steps:

[0028] Step 1. Take fresh midge shrimp raw materials, clean the midge shrimp with fresh water, then put the washed midge shrimp in boiling water for 1 minute, put them into a meat grinder after blanching, add ice and grind for 1 minute, add The amount of ice is 1 / 5 of the weight of the midges, and then the twisted midges are transferred to a vacuum freeze dryer for drying; after drying, they are put into a pulverizer, and liquid nitrogen is added at room temperature, and the pulverization is carried out at intervals , crushed for 1 minute each time, stopped for 20 seconds, and crushed 5 times for a total of 5 minutes. The amount of nitrogen passing through the crush was 160 mL / 100 g, and the crushed midge and shrimp powder was obtained for subsequent use; the midge and shrimp powder was sieved with a 40-mesh sieve and collected less than 40 mesh midge and shrimp powder, place...

Embodiment 2

[0033] A preparation method of shrimp-flavored green wheat biscuits, comprising the following steps:

[0034] Step 1. Take fresh midge shrimp raw materials, clean the midge shrimp with fresh water, then put the washed midge shrimp in boiling water for 1 minute, put them into a meat grinder after blanching, add ice and grind for 1 minute, add The amount of ice is 1 / 3 of the weight of the midge shrimp, and then the twisted midge shrimp is transferred to a vacuum freeze dryer for drying; after drying, it is put into a pulverizer, and liquid nitrogen is added at room temperature, and the pulverization is carried out at intervals , crushed for 1 minute each time, stopped for 20 seconds, and crushed 5 times for a total of 5 minutes. The amount of nitrogen passing through the crush was 260 mL / 100 g, and the crushed midge and shrimp powder was obtained for subsequent use; the midge and shrimp powder was sieved with a 40-mesh sieve, and collected less than 40 mesh midge and shrimp powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com