Aerogenesis fermentation dairy product and production method thereof

A fermented milk product and fermented milk technology, applied in dairy products, milk preparations, applications, etc., can solve the problem of low gas production of lactic acid bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

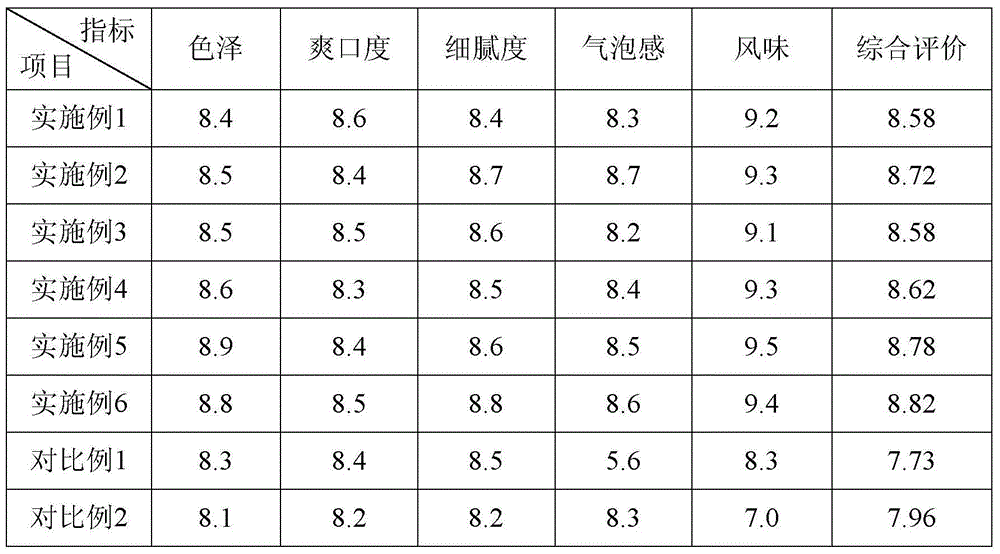

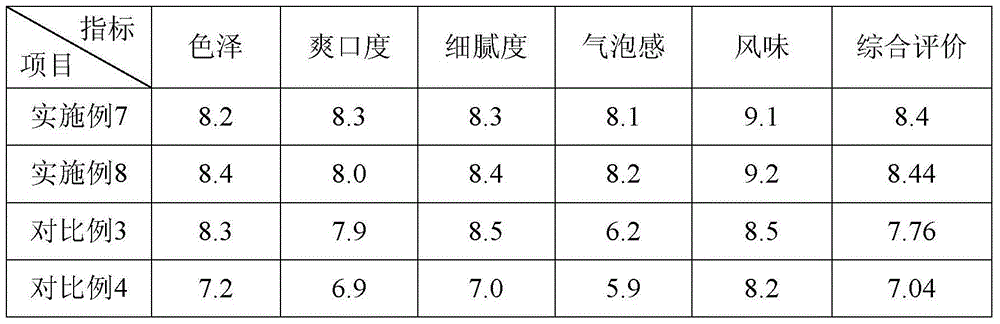

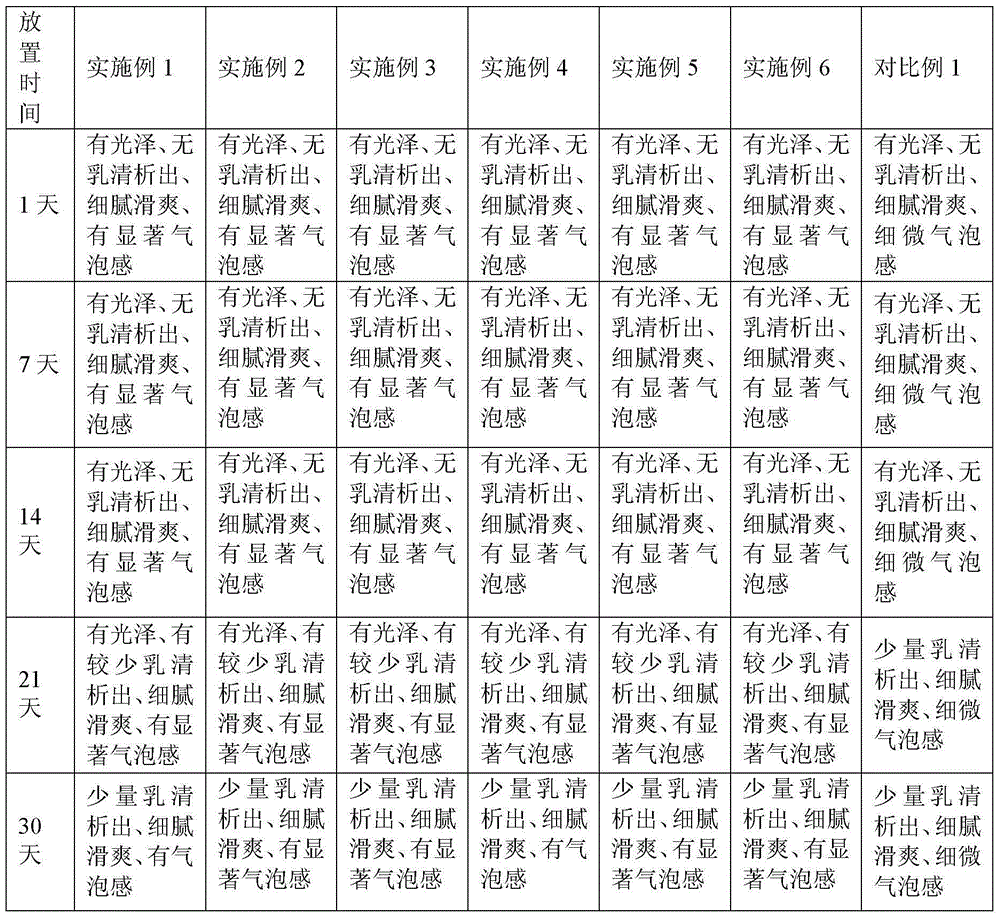

Examples

Embodiment 1

[0039] 1. Raw material formula (based on 1000g fermentation substrate):

[0040] Fermentation substrate: 90g of white sugar; 0.7g of sodium citrate; the rest of raw milk;

[0041] Mixed fermentation strains (Lactococcus lactis subsp. cremoris, Leuconostoc, Lactococcus lactis subsp. diacetyl and Lactococcus lactis subsp. lactis, mixing ratio=0.5:1:1:0.5): 0.008g.

[0042] 2. Production method:

[0043] 1. Stir and disperse the raw milk (fresh milk) and white sugar in the ingredients at a high speed of 65°C for 30 minutes to mix evenly, then add sodium citrate to obtain a milk mixture;

[0044] 2. The mixed material is degassed and homogenized at 65°C and 18MP pressure;

[0045] 3. The homogenized mixed material is sterilized at 95°C for 300s;

[0046] 4. Cool the sterilized material to 30°C, add fermentation strains, stir and mix evenly;

[0047] 5. Ferment at 30°C for 18 hours, the acidity reaches 74°T, stir to break the emulsion, cool down to stop the fermentation;

[00...

Embodiment 2

[0051] 1. Raw material formula (based on 1000g fermentation substrate):

[0052] Fermentation substrate: 60g of white sugar; 4g of starch; 0.2g of pectin; 0.8g of sodium citrate; the rest of raw milk;

[0053] Mixed fermentation strains (Lactococcus lactis subsp. cremoris, Leuconostoc, Lactococcus lactis subsp. diacetyl and Lactococcus lactis subsp. lactis, mixing ratio = 1:3:2:1): 0.009g; Lactobacillus bulgaricus : 0.002g; Streptococcus thermophilus 0.002g.

[0054] 2. Production method:

[0055] 1. Mix all the ingredients except for the strains at 70°C for 25 minutes at high speed to mix evenly;

[0056] 2. The mixed material is degassed and homogenized at 68°C and 20MP pressure;

[0057] 3. The homogenized mixture is sterilized at 110°C for 10 minutes;

[0058] 4. Cool the sterilized material to 35°C, add fermentation strains, stir and mix evenly;

[0059] 5. Ferment at 35°C for 14 hours, the acidity reaches 76°T, the emulsion is broken and the temperature is lowered t...

Embodiment 3

[0063] 1. Raw material formula (based on 1000g fermentation substrate):

[0064] Fermentation substrate: white sugar 40g; modified starch 2g; agar 0.2g; pectin 0.4g; sodium citrate 0.9g;

[0065] Mixed fermentation strains (Lactococcus lactis subsp. cremoris, Leuconostoc sp., Lactococcus lactis subsp. diacetyl and Lactococcus lactis subsp. lactis, mixing ratio = 1.5:4:2.5:1): 0.01g; Bacillus 0.005g.

[0066] 2. Production method:

[0067] 1. All the ingredients except for the bacteria were stirred and dispersed at 68°C for 25 minutes to mix them evenly;

[0068] 2. The mixed material is degassed and homogenized at 65°C and 20MP pressure;

[0069] 3. The homogenized mixed material is sterilized at 121°C for 4s;

[0070] 4. Cool the sterilized material to 37°C, add fermentation strains, stir and mix evenly;

[0071] 5. Ferment at 37°C for about 12 hours, and when the acidity reaches 78°T, break the emulsion and cool down to stop the fermentation;

[0072] 6. Pour the ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com