Household refuse direct heating oxygen-deficient gasification kiln

A domestic waste, direct technology, applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve the problems of easy generation of harmful gases, fluctuations in combustion temperature, low combustion efficiency, etc. High thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

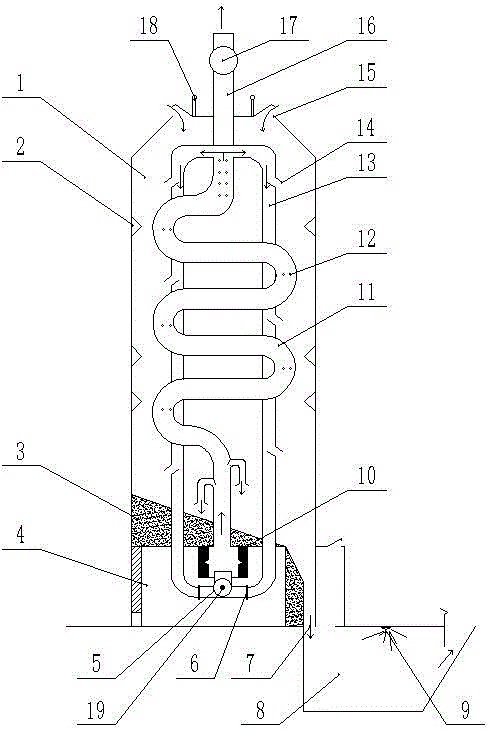

[0028] An oxygen-poor oxidation kiln for direct heating of domestic waste, comprising a kiln body 1, a feed port 15, a serpentine heat supply pipe 11, an exhaust pipe 16, a heater 10, a blower 5, a thermometer 2, a discharge port 7 and Charcoal pool8. The upper end of the kiln body 1 is provided with a feed port 15, the heater 10 is arranged at the lower end of the kiln body 1, the serpentine heat supply pipe 11 is arranged in the furnace body, the lower end of the serpentine heat supply pipe 11 is connected with the heater 10, and the serpentine shape The top end of the heat supply pipe 11 is connected to an exhaust pipe 16 . An air hole A12 is provided on the serpentine heat supply pipe 11 , and a blower 5 is provided below the heater 10 . The heater 10 is an electromagnetic induction heater. The blower 5 is provided with an air flow sensor 19. According to the set value of the oxygen supply ratio in the kiln, the air flow sensor cooperates with the valve on the blower to ...

Embodiment 2

[0031] An oxygen-poor oxidation kiln for direct heating of domestic waste, comprising a kiln body 1, a feed port 15, a serpentine heat supply pipe 11, an exhaust pipe 16, a heater 10, a blower 5, a thermometer 2, a discharge port 7 and Charcoal pool8. The upper end of the kiln body 1 is provided with a feed inlet 15 , and the bottom of the kiln body 1 is provided with an isolated working room 4 . The heater 10 is arranged at the lower end of the kiln body 1, the serpentine heat supply pipe 11 is arranged in the furnace body, the lower end of the serpentine heat supply pipe 11 is connected with the heater 10, and the top end of the serpentine heat supply pipe 11 is connected with the exhaust pipe 16 . An air hole A12 is provided on the serpentine heat supply pipe 11 , and a blower 5 is provided below the heater 10 . The heater 10 and the blower 5 are arranged in the isolation work room 4; the shutters are also arranged in the isolation work room 4; the shutters are installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com