Silicon carbide deoxidation steel production process

A technology of silicon carbide and process, which is applied in the field of steelmaking process and silicon carbide deoxidation steelmaking process, can solve the problem of high aluminum consumption, achieve the effect of reducing aluminum consumption per ton of steel, the effect is obvious, and the smelting process is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

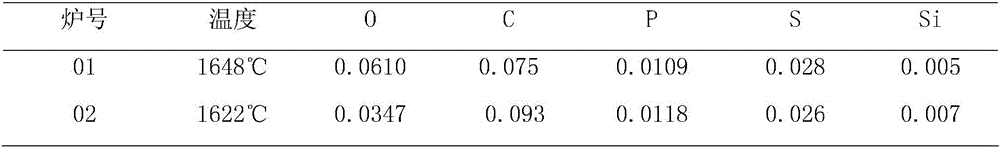

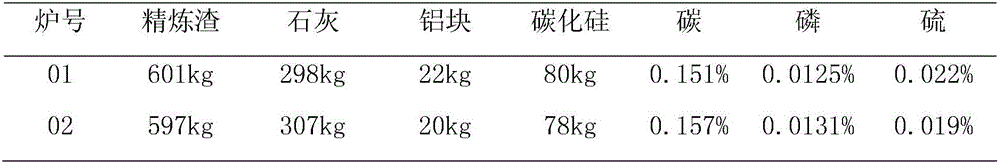

[0018] A control process for the production of deep deoxidized steel by silicon carbide deoxidation in the smelting process. The process optimizes the deoxidation system and slagging system of the converter tapping, and adds an appropriate amount of silicon carbide according to the oxygen value at the end of the converter tapping, and the silicon carbide is rapidly formed in the early stage of the LF furnace. Deoxidation slagging, aluminum wire fine-tuning of aluminum in molten steel to produce deep deoxidized steel process, aluminum content in molten steel is kept in the range of 0.010-0.030% to control the amount of aluminum wire feeding, soft stirring for more than 10 minutes after desulfurization and alloying.

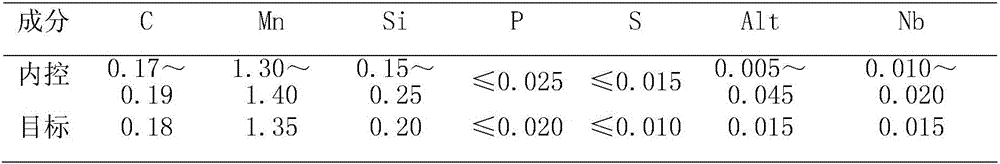

[0019] In this embodiment, Q345 steel grade is selected, and it is smelted in a 150-ton converter and a 150-ton ladle furnace. The chemical composition of its Q345 is shown in Table 1, and the entire smelting process is controlled as follows:

[0020] Table 1 Main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com