Method for purification treatment of sucralose water crystallization mother liquor

A technology of sucralose and crystallization mother liquor, which is applied in the direction of chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of low yield, low purity of crude sucralose, and difficulty in industrial application, and achieve improvement Purity, reducing the amount of discharged waste water, and reducing the pressure of waste water treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

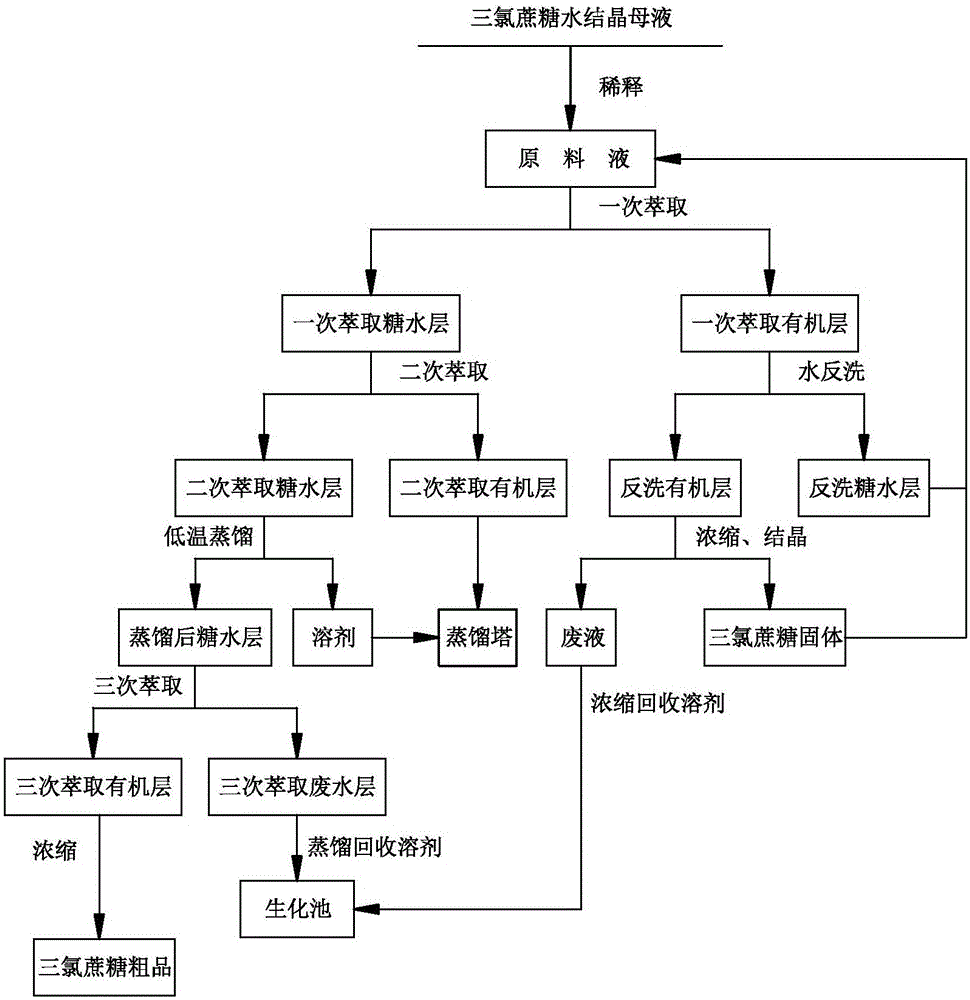

[0029] A kind of purification treatment method of the sucralose water crystallization mother liquor of the present embodiment, such as figure 1 As shown, the steps are as follows:

[0030] (1) Raw material liquid extraction and impurity removal

[0031] (1-1) The purity of sucralose in the water crystallization mother liquor is 92.4%. After the mother liquor is diluted with water, a raw material solution with a concentration of 22% is obtained; 660L of ethyl acetate is added to the 1500L raw material solution for one-time extraction and impurity removal, and the mixture is stirred for 30 minutes. Stand still for 60min to obtain primary extraction sugar water layer 1450L and primary extraction organic layer 710L; wherein, primary extraction organic layer is processed in the following step (3);

[0032] (1-2) Add 1800L cyclohexane to the above-mentioned 1450L primary extraction sugar water layer for secondary extraction, stir for 30 minutes, and let it stand for 30 minutes to r...

Embodiment 2

[0040] A kind of purification treatment method of the sucralose water crystallization mother liquor of the present embodiment, such asfigure 1 As shown, the steps are as follows:

[0041] (1) Raw material liquid extraction and impurity removal

[0042] (1-1) The purity of sucralose in the water crystallization mother liquor is 93.2%. After the mother liquor is diluted with water, a raw material solution with a concentration of 17% is obtained; 510L of butyl acetate is added to the 1500L raw material solution for one extraction and removal of impurities, and the mixture is stirred for 30 minutes. Stand still for 60min to obtain primary extraction sugar water layer 1450L and primary extraction organic layer 560L; wherein, primary extraction organic layer is processed in the following step (3);

[0043] (1-2) Add 1500L toluene to the above-mentioned 1450L primary extraction sugar water layer for secondary extraction, stir for 30min, and let stand for 30min to remove the organic s...

Embodiment 3

[0051] A kind of purification treatment method of the sucralose water crystallization mother liquor of the present embodiment, such as figure 1 As shown, the steps are as follows:

[0052] (1) Raw material liquid extraction and impurity removal

[0053] (1-1) The purity of sucralose in the water crystallization mother liquor is 92.0%. After the mother liquor is diluted with water, a raw material solution with a concentration of 25% is obtained; 563L of n-butanol is added to the 1500L raw material solution for one extraction and removal of impurities, and stirred for 30min. Stand still for 60min to obtain the first extraction sugar water layer 1450L and the first extraction organic layer 613L; wherein, the first extraction organic layer is processed in the following step (3);

[0054] (1-2) Add 1800L carbon tetrachloride to the above-mentioned 1450L primary extraction sugar water layer for secondary extraction, stir for 30min, and let it stand for 30min to remove the organic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com