Cement-based self-leveling mortar

A self-leveling mortar and cement-based technology, applied in the field of self-leveling mortar, can solve the problems of increased segregation and settlement, accelerated surface, and easy cracking of the surface, and achieves the effect of significantly reducing the cost and reducing the cost of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

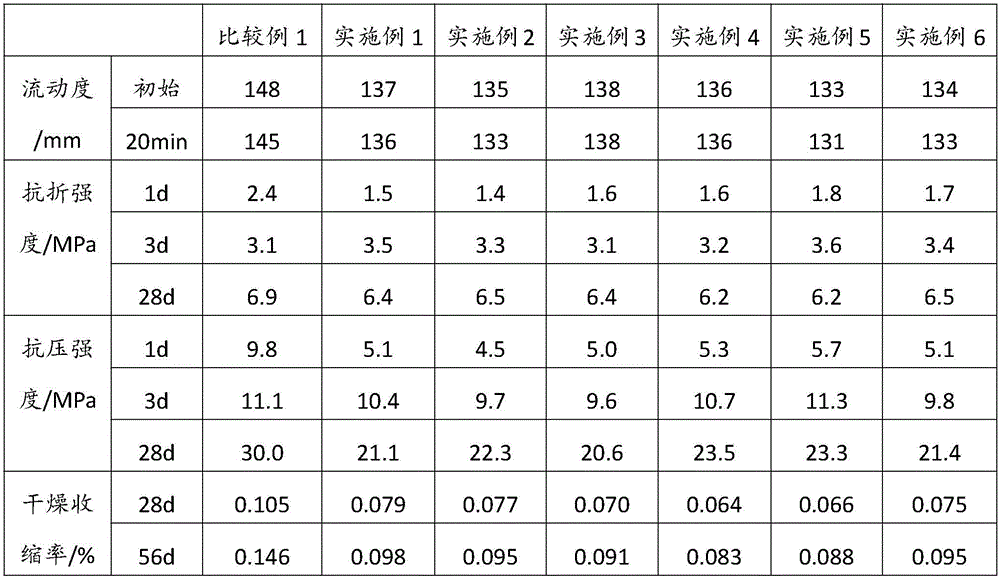

Examples

Embodiment 1

[0040] In terms of mass fraction, the component ratio is as follows: 160 parts of PⅡ52.5 Portland cement, 55 parts of CA50 aluminate cement, 35 parts of anhydrous gypsum, 15 parts of bentonite, 125 parts of heavy calcium powder, 20-40 mesh water washing river 200 parts of sand, 200 parts of washed river sand of 40-70 mesh, 200 parts of washed river sand of 70-140 mesh, 5 parts of redispersible latex powder, 0.5 part of water reducer, 0.6 part of retarder, 0.8 part of cellulose ether, 0.8 parts of defoaming agent, 0.3 parts of lithium carbonate, 0.3 parts of polypropylene fiber, and a water-material mass ratio of 0.22 to prepare cement-based self-leveling mortar.

Embodiment 2

[0042] In terms of mass fraction, the ratio of raw materials is as follows: 170 parts of PO42.5 Portland cement, 45 parts of CA50 aluminate cement, 35 parts of anhydrous gypsum, 20 parts of bentonite, 70 parts of heavy calcium powder, 20-40 mesh washing 150 parts of river sand, 250 parts of washed river sand of 40-70 mesh, 250 parts of washed river sand of 70-140 mesh, 5 parts of redispersible latex powder, 0.6 part of water reducer, 0.5 part of retarder, 1 part of cellulose ether , 1.2 parts of defoaming agent, 0.5 part of lithium carbonate, 0.4 part of polypropylene fiber, and the mass ratio of water to material is 0.21 to prepare cement-based self-leveling mortar.

Embodiment 3

[0044] In terms of mass fraction, the raw material components are as follows: 165 parts of PO42.5 Portland cement, 45 parts of 52.5 sulfoaluminate cement, 40 parts of anhydrite, 15 parts of bentonite, 120 parts of heavy calcium powder, 20-40 mesh 150 parts of washed river sand, 250 parts of washed river sand of 40-70 mesh, 200 parts of washed river sand of 70-140 mesh, 10 parts of redispersible latex powder, 0.4 part of water reducing agent, 0.5 part of retarder, 0.7 part of cellulose ether 1 part, 1 part of defoamer, 0.5 part of lithium carbonate, 0.3 part of polypropylene fiber, and the mass ratio of water to material is 0.21 to prepare cement-based self-leveling mortar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com