Method for preparing potassium dihydrogen phosphite

A technology of potassium dihydrogen phosphite and phosphorous acid, which is applied in the chemical industry, can solve the problems of long reaction time and the need for crystallization process of potassium dihydrogen phosphite, achieve short reaction time, improve storability and transportability, and simplify production Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

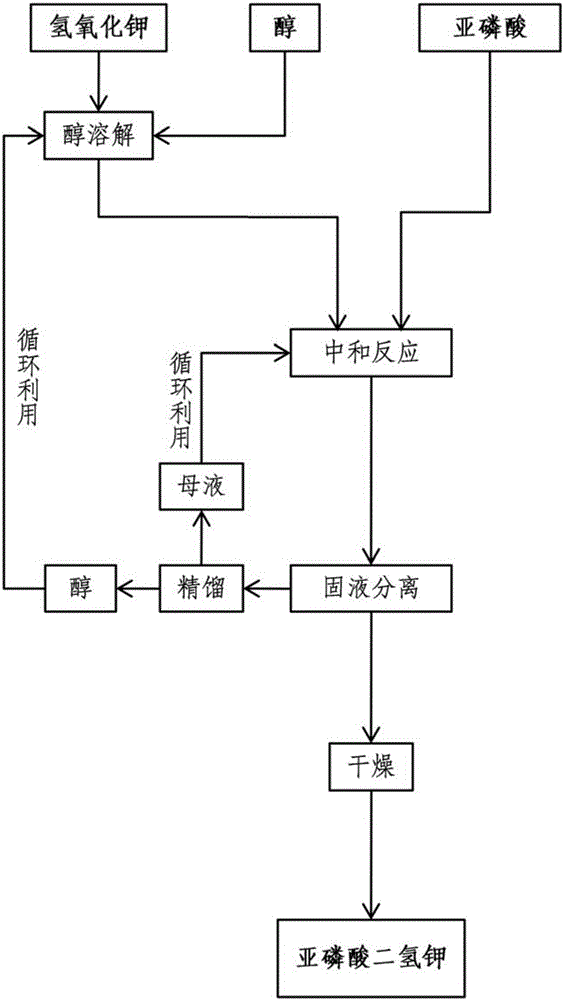

[0035] use as figure 1 Shown the method of the present invention, with 10870t 85% solid potassium hydroxide, take ethanol as solvent (recycling) to obtain potassium hydroxide alcoholic solution through alcohol dissolving, then neutralize reaction with 13736t98.5% solid phosphorous acid, The solution concentration of potassium hydroxide alcohol is 20g / 100g. The molar ratio of potassium hydroxide alcoholic solution and phosphorous acid used for neutralization reaction between potassium hydroxide and phosphorous acid is 1:1.04; 2 hours; neutralization reaction terminal pH value is 4.5. The material after the neutralization reaction is subjected to solid-liquid separation and drying to obtain potassium dihydrogen phosphite. After testing, the purity of the potassium dihydrogen phosphite obtained after drying reaches more than 99 wt%. The liquid obtained after solid-liquid separation is rectified to recover alcohol, and the obtained alcohol is used as potassium hydroxide alcohol...

Embodiment 2

[0038] use as figure 1Shown the inventive method, with 5435t 85% solid potassium hydroxide, take ethanol as solvent (recycling) to obtain potassium hydroxide alcoholic solution through alcohol dissolution, then neutralize reaction with 6868t98.5% solid phosphorous acid, The solution concentration of potassium hydroxide alcohol is 20g / 100g. The molar ratio of potassium hydroxide alcoholic solution and phosphorous acid used for neutralization reaction between potassium hydroxide and phosphorous acid is 1:1.04; 3 hours; neutralization reaction terminal pH value is 4.4. The material after the neutralization reaction is subjected to solid-liquid separation and drying to obtain potassium dihydrogen phosphite. After testing, the purity of the potassium dihydrogen phosphite obtained after drying reaches more than 99 wt%. The liquid obtained after solid-liquid separation is rectified to recover alcohol, and the obtained alcohol is used as an alcohol solvent for potassium hydroxide f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com