Method for producing levulinic acid by efficiently catalyzing saccharides

A technology of levulinic acid and sugars, which is applied in the field of biomass catalytic utilization, can solve the problems of high reaction temperature, difficulty in separating levulinic acid from the catalyst, low catalytic activity, etc., and achieve the effect of high-efficiency catalytic conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) 1g glucose, 0.5g Amberlite36 resin and 5g acetic acid mass concentration are mixed with 90% acetic acid aqueous solution;

[0026] (2) Heating to 80°C in a reactor equipped with a reflux device, and reacting for 20 hours;

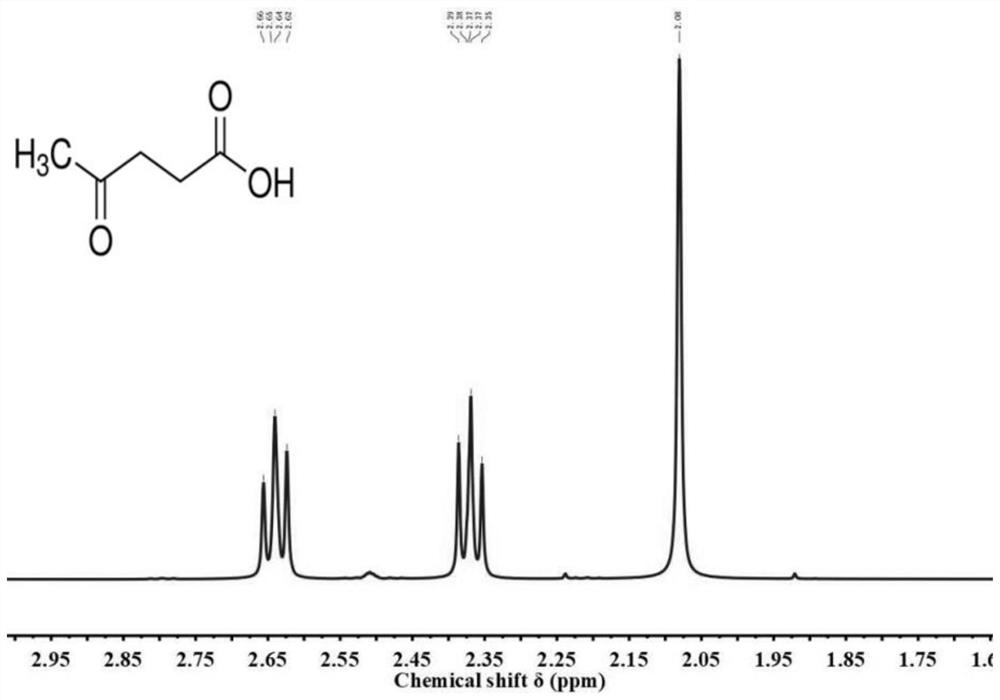

[0027] (3) Cooling and filtering after the reaction finishes, the filtered solid is a catalyst, which is recovered after drying; the filtrate is distilled under reduced pressure, and the solvent distilled out is recycled; the viscous paste substance 0.8g obtained by distillation has a high content of levulinic acid 88wt%, the structure of levulinic acid is as figure 1 shown.

Embodiment 2

[0029] (1) 1g glucose, 0.4g Amberlite35 resin are mixed with 20g acetic acid;

[0030] (2) Heating to 100°C in a reactor equipped with a reflux device, and reacting for 15 hours;

[0031] (3) cooling and filtering after the reaction finishes, the filtered solid is a catalyst, which is reclaimed after drying; the filtrate is distilled under reduced pressure, and the solvent distilled out is recycled; the viscous paste substance 0.6g that distillation obtains, the levulinic acid content 90wt%.

Embodiment 3

[0033] (1) 1g glucose, 0.5g Amberlite36 resin and 2g acetic acid mass concentration are mixed with 85% acetic acid aqueous solution;

[0034] (2) Heating to 120°C in a sealed reactor and reacting for 10 hours;

[0035] (3) Cooling and filtering after the reaction finishes, the filtered solid is a catalyst, which is reclaimed after drying; the filtrate is distilled at atmospheric pressure, and the distilled solvent is recycled; the viscous paste substance 0.7g that distillation obtains, the levulinic acid content It is 89wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com