Method for preparing nano powder with strong ultraviolet absorption function

A functional nano-ultraviolet technology, which is applied in the direction of nanotechnology, nanotechnology, and nanotechnology for materials and surface science, can solve the problems of unfavorable industrial application, high cost, and large surface polarity, so as to achieve good shielding of ultraviolet rays, High production efficiency, no skin irritation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

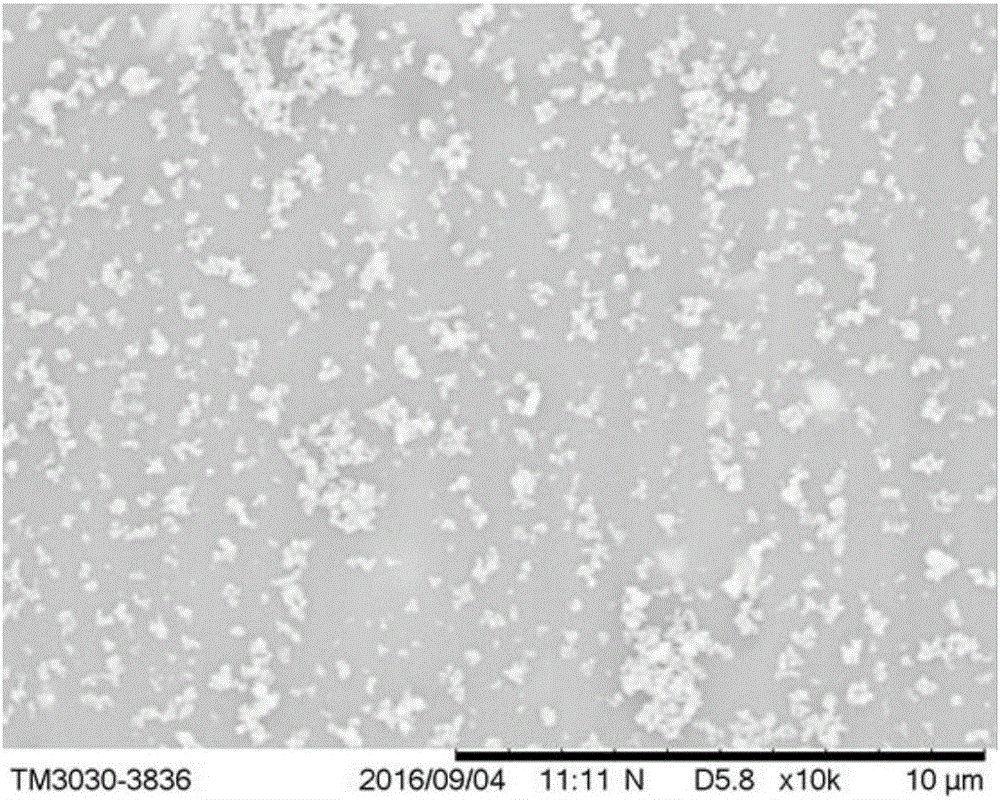

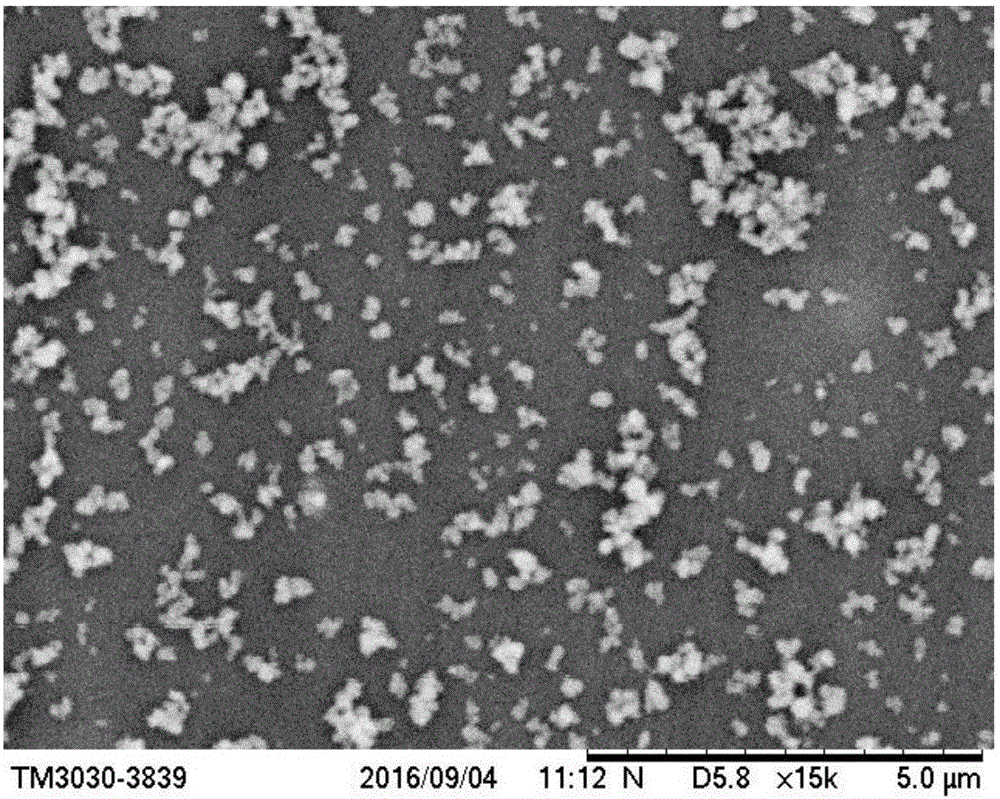

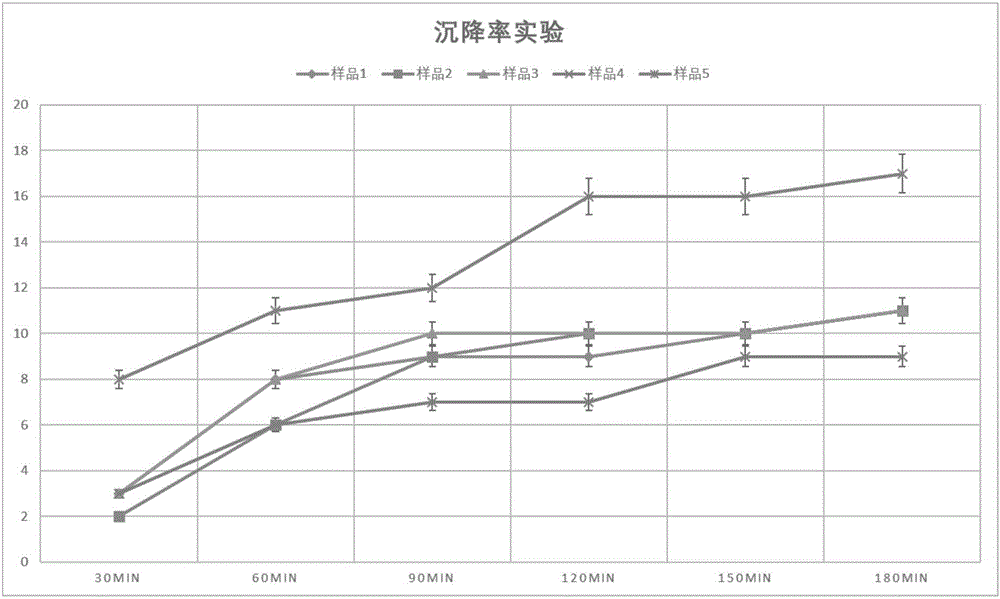

[0038] Weigh 3 tons of zinc oxide coarse powder, add it to a mechanical pulverizer with a speed of 350rpm, and pulverize it for 45 minutes, and at the same time use ultrasonic high-speed atomization to assist pulverization. The ultrasonic power is 250W, and the high-speed atomization speed is 24000rpm. Easy to weigh; weigh 0.15t of surface modifier mercaptoacetic acid according to the ratio of 5wt.%, adjust the airflow pulverizer, and the gas flow rate is 3m 3 / min, the gas pressure is 0.6MPa, the air temperature is 100°C, the concentration of the modifier solution is 5wt.%, the flow rate of the modifier solution is 1ml / min, the atomization is 1-20μm, spray the modifier after the crushing, and crush After completion, zinc oxide nanopowders with an average diameter of 100 nanometers, which have been surface-modified and uniformly dispersed are obtained.

[0039] This is sample 1.

Embodiment 2

[0041] Weigh 3t of titanium dioxide coarse powder, add it to a mechanical pulverizer with a speed of 300rpm, and pulverize it for 60 minutes, and at the same time use ultrasonic high-speed atomization to assist pulverization. The ultrasonic power is 200W, and the high-speed atomization speed is 22000rpm. Weighing; weigh 0.24t of amino acid surface modifier according to 8wt.%, adjust the airflow pulverizer, and the gas flow rate is 3m 3 / min, the gas pressure is 0.6MPa, the air temperature is 110°C, the concentration of the modifier solution is 6wt.%, the flow rate of the modifier solution is 1ml / min, the atomization is 1-20μm, spray the modifier after the crushing, and crush After completion, titanium dioxide powder with an average diameter of 100 nanometers, which has been surface-modified and uniformly dispersed is obtained.

[0042] This is sample 2.

Embodiment 3

[0044] Weigh 3 tons of cadmium oxide coarse powder, add it to a mechanical pulverizer with a speed of 250rpm, and pulverize it for 45 minutes, and at the same time use ultrasonic high-speed atomization to assist pulverization. The ultrasonic power is 250W, and the high-speed atomization speed is 20000rpm. Easy to weigh; weigh 0.18t of glycerol according to the ratio of 6wt.%, adjust the airflow pulverizer, and the gas flow rate is 3m 3 / min, the gas pressure is 0.6MPa, the air temperature is 100°C, the concentration of the modifier solution is 4wt.%, the flow rate of the modifier solution is 1ml / min, the atomization is 1-20μm, spray the modifier after the crushing, and crush After completion, titanium dioxide powder with an average diameter of 120 nanometers, which has been surface-modified and uniformly dispersed is obtained.

[0045] This is sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com