Bulk material storage yard automatic warehouse discharge system

A bulk material and storage yard technology, which is applied in the field of bulk material storage yard automatic storage system, can solve problems such as time-consuming and labor-intensive, low efficiency, and lack of real-time measurement of storage volume, and achieve the effect of reducing labor requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention provides a new type of automatic warehouse-out system for bulk material yards, which can solve the above two problems through material level monitoring and automatic measurement.

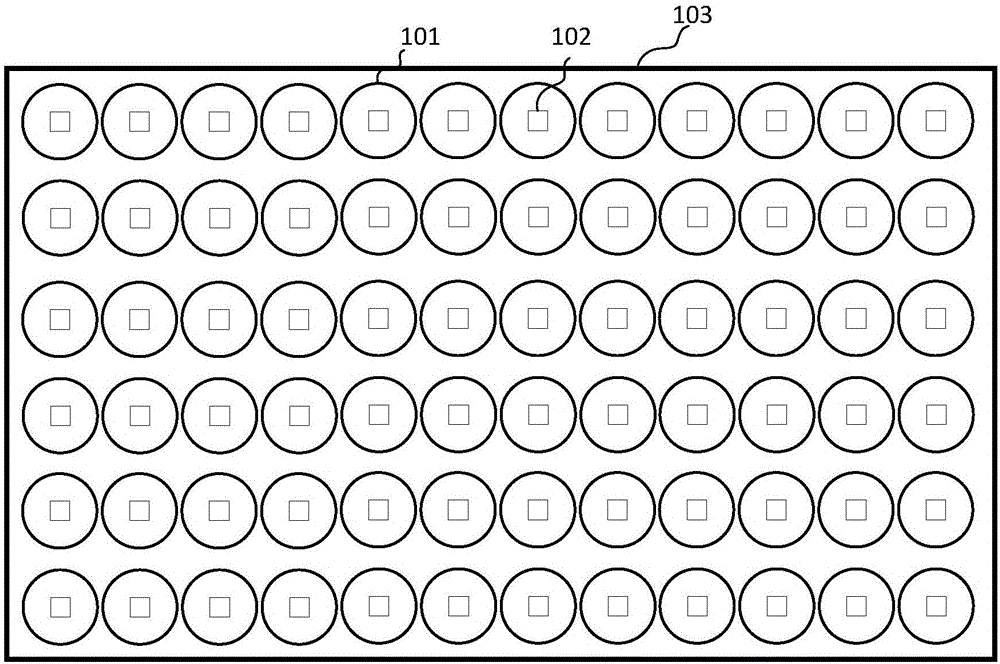

[0022] The present invention does not change the stacking mode of the above-ground materials in the bulk material storage yard, and the bulk materials are stacked as figure 1 shown. The material pile 101 falls into the ground through the electric arc gate 102, and is fed and transported out of the field by a vibrating feeder.

[0023] For bulk material yards, monitoring the height of each stockpile can calculate the inventory situation of each storage location, that is, the measured height of the stockpile reaches the design height and the storage location is full, and the measured height of the stockpile is zero ( That is, the ground) is an empty storage location, and each height can display the inventory status of the storage location in the form of a percentage.

[0024] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com