Sulfur-doped carbon nitride photocatalyst as well as preparation method and application thereof

A carbon nitride light and sulfur doping technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of small specific surface area, reduced absorption, and unsatisfactory photocatalytic performance, etc. Achieve the effect of large specific surface area, strong light absorption, strong photocatalytic degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Put 10g of thiourea in a crucible and cover it, calcined in a muffle furnace, the calcining temperature is 550°C, the holding time is 4 hours, and the heating rate is 2.3°C / min; after natural cooling, it is ground into powder to obtain sulfur-doped graphite Phase carbon nitride (CN-T-1), weighed 1.2g and put it in a crucible without a cover, spread it out, and calcined again. The calcining temperature was 500°C, the holding time was 2 hours, and the heating rate was 5°C / min . After natural cooling, a high specific surface area modified carbon nitride photocatalyst (CN-T-2) was obtained with a yield of about 12%.

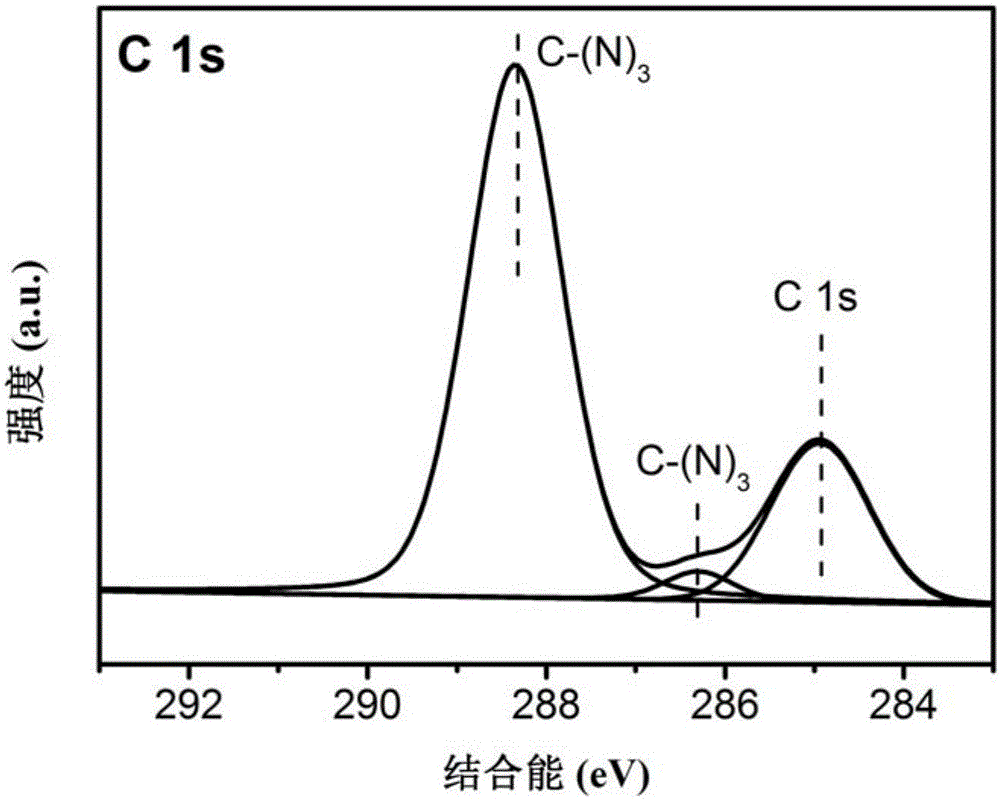

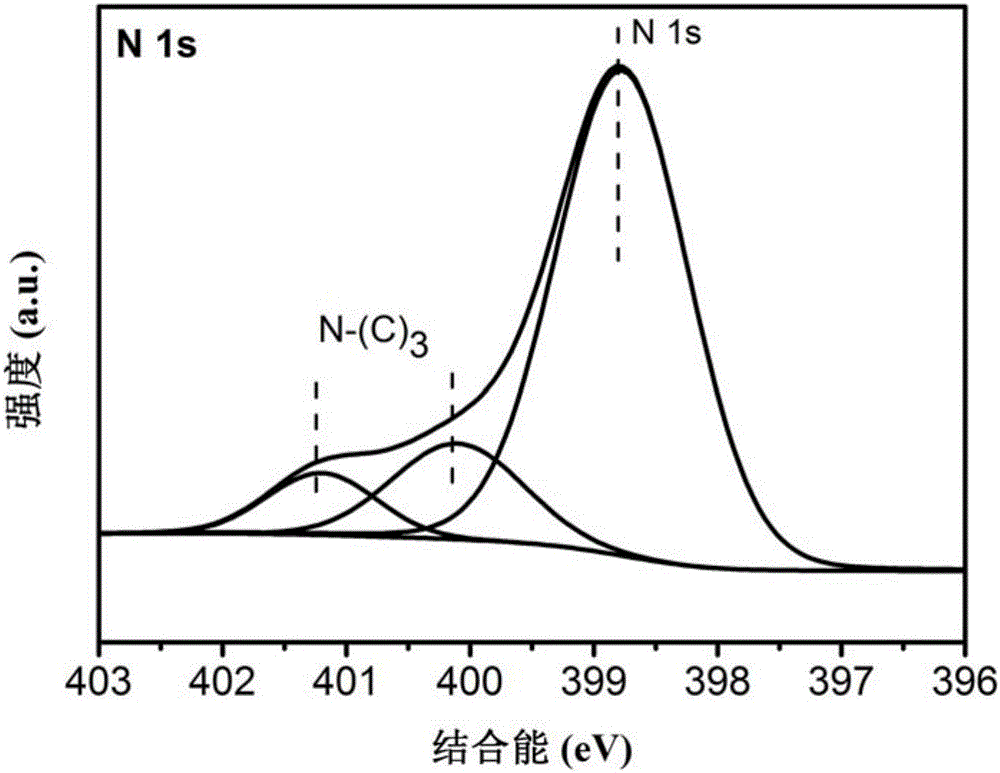

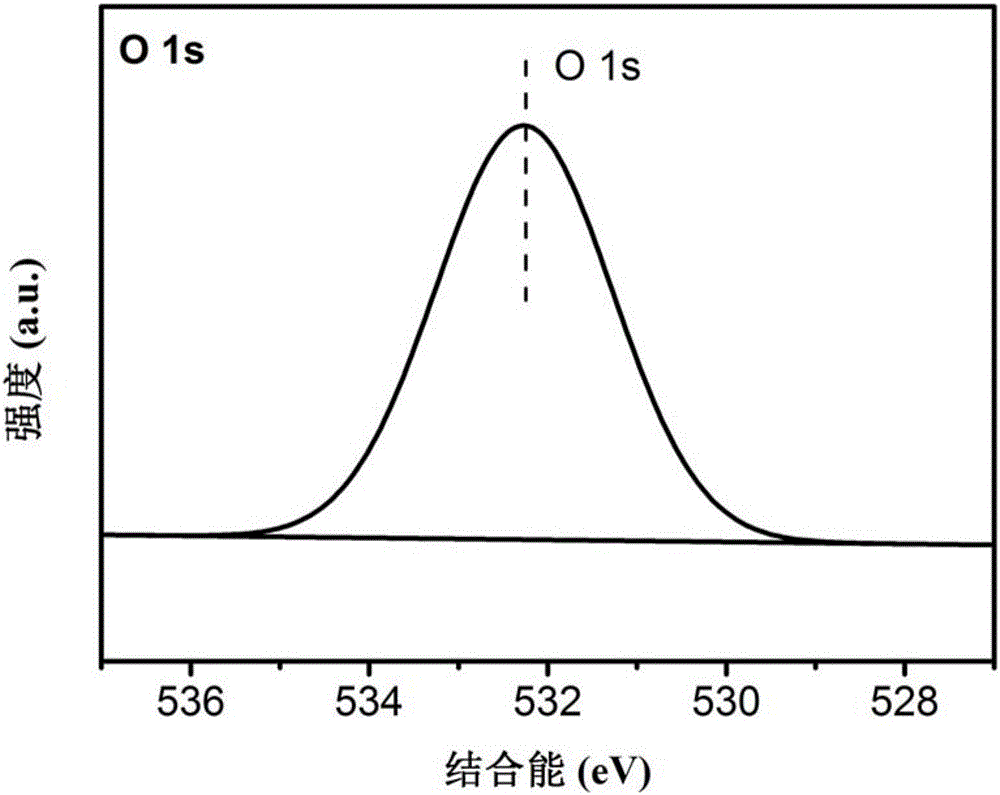

[0036] The photocatalyst prepared in embodiment 1 is carried out XPS, DRS, XRD etc. characterization, the result is as follows Figure 1-7 shown.

[0037] in conclusion: Figure 1~4 Shown are the XPS diagrams of C, O, N, and S of CN-T-2 respectively. It can be seen from the figure that the composition and valence state of C, O, and N are consistent with tho...

Embodiment 2

[0042] Put 10g of thiourea in a crucible and cover it, calcined in a muffle furnace, the calcining temperature is 550°C, the holding time is 4 hours, the heating rate is 2.3°C / min; after natural cooling, grind it into powder, weigh 1.2g Put it in a crucible without a cover, spread it out, and calcinate again, the calcining temperature is 500°C, the holding time is 1.0 hour, and the heating rate is 5°C / min. After natural cooling, a high specific surface area modified carbon nitride photocatalyst (CN-T-21 hours) was obtained, and the yield was about 18%.

Embodiment 3

[0044] Put 10g of thiourea in a crucible and cover it, calcined in a muffle furnace, the calcining temperature is 550°C, the holding time is 4 hours, the heating rate is 2.3°C / min; after natural cooling, grind it into powder, weigh 1.2g Put it in a crucible without a cover, spread it out, and calcinate again, the calcining temperature is 500°C, the holding time is 3 hours, and the heating rate is 5°C / min. After natural cooling, a high specific surface area modified carbon nitride photocatalyst (CN-T-23 hours) was obtained with a yield of about 8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com