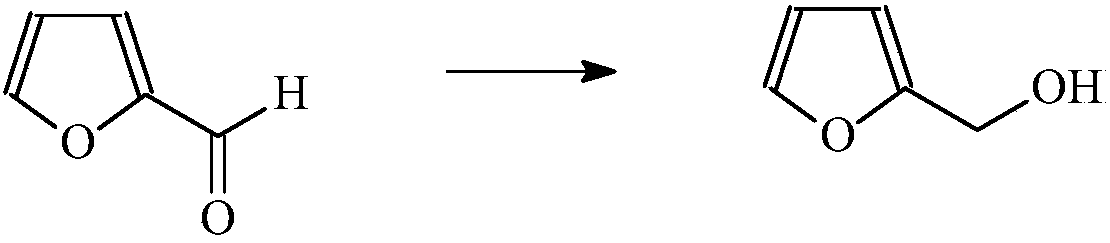

Copper-containing catalyst and preparation method thereof

A catalyst and hydrogen preparation technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of catalyst occupation and high cost, and achieve improved catalytic activity, reduced production costs, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

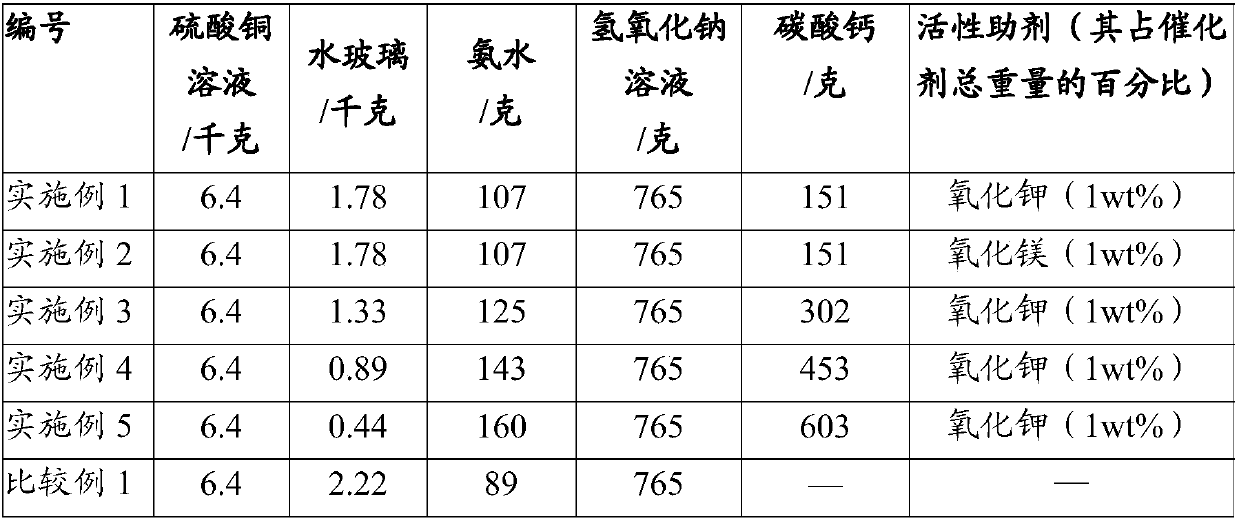

[0041] The present invention also provides a kind of preparation method of catalyst, it comprises the steps:

[0042] (1) Under continuous stirring, silicon source and ammonia flow are added to the copper sulfate solution to form a mixed solution; wherein, calcium carbonate is dispersed in the copper sulfate solution, and the silicon source is water glass or silicon Sol;

[0043] (2) Under continuous stirring, the sodium hydroxide solution is gradually added to the mixed solution, and after the addition is completed, the compressed gas is introduced to release the ammonia gas, thereby forming a slurry, and the Cu in the slurry is 2+ Not more than 30ppm;

[0044] (3) Obtain a filter cake after filtering the slurry obtained in step (2), and use compressed gas to dry the filter cake;

[0045] (4) washing the filter cake dried in step (3) with water until the pH value of the filtrate is 7 to 8, and then drying the washed filter cake with compressed air;

[0046] (5) heating the...

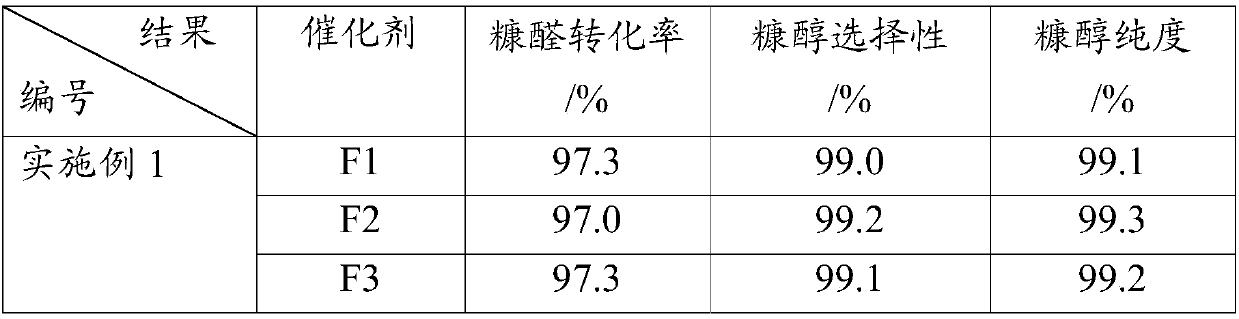

Embodiment 1

[0068] (1) 151g calcium carbonate is dispersed in the copper sulfate solution that contains 1.4kg copper sulfate pentahydrate to form mixed solution, then this mixed solution is placed in container. Add 1.78kg of water glass and 107g of ammonia water into the separatory funnel respectively, and then add the water glass and ammonia water into the container containing the mixed solution in a double parallel flow according to the flow rate of water glass 10ml / min and ammonia water 0.44ml / min In the feeding process, the stirring speed was 120rpm. After the feeding was completed, the stirring was continued for 30 min.

[0069] (2) According to the flow rate of 5ml / min, 765g of sodium hydroxide solution was gradually fed into the above reaction system, and the stirring speed during the feeding process was 120rpm. After feeding, continue to stir, and at the same time, pass compressed air into the bottom of the container for about 2 hours, so as to ensure that all the ammonia gas esc...

Embodiment 2

[0076] Except that potassium oxide powder was replaced by magnesium oxide, other steps and conditions were the same as in Example 1 to obtain catalyst G.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com