Low-carbon olefin preparation catalyst and preparation method thereof

A technology for low-carbon olefins and catalysts, which is applied in the field of high-activity and stable supported iron-based syngas-based low-carbon olefin catalysts and its preparation, and can solve the problems of low-carbon olefin catalyst activity and stability, low CO conversion, and low-carbon olefin catalysts. Catalyst cost is high, to achieve the effect of outstanding comprehensive performance, improved conversion rate, and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] Weigh commercially available alumina (pore volume is 0.96ml / g, specific surface area is 286.81m 2 / g, saturated water absorption is 145ml / g, provided by Fushun branch of Sinopec Catalyst Co., Ltd., the following examples and comparative examples all use the alumina), adopt the unsaturated spray impregnation method to impregnate nickel and gallium molar concentrations are respectively 0.5mol / L, 1mol / L nickel nitrate and gallium nitrate mixed aqueous solution, impregnation temperature is 50°C, impregnation time is 3h, impregnation amount is 20% of the amount of saturated absorption solution of alumina carrier, dried at 120°C for 5h, and calcined at 850°C Under roasting for 6h. The unsaturated carrier after roasting is sprayed and dipped in triethylamine aqueous solution, and the triethylamine aqueous solution spray volume is 35% of the total saturated water absorption of the carrier used, and the mass content of triethylamine in the triethylamine aqueous solution is 8% of...

example 2

[0026]Weigh commercially available alumina, impregnate nickel nitrate and gallium nitrate mixed aqueous solutions with nickel and gallium molar concentrations of 1.5 mol / L and 3 mol / L respectively by unsaturated spray impregnation method, immersion temperature at 60°C, immersion time for 2 hours, The amount is 40% of the saturated absorption solution of the alumina carrier, dried at 90°C for 10h, and calcined at 900°C for 4h. The unsaturated carrier after roasting is sprayed and dipped in morphine aqueous solution, the spray volume of morphine aqueous solution is 10% of the total saturated water absorption of the carrier used, the mass content of morphine in the morphine aqueous solution is 2% of the carrier mass, oxygen is generated for 5 hours after spraying and dipping, Dry at 90°C for 8h. The rest are the same as in Example 1, and the prepared catalyst is denoted as C-2, and the 300h evaluation results are shown in Table 1.

example 3

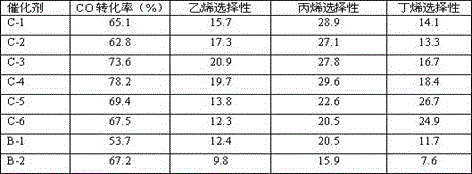

[0028] Except that 5% ammonium thiocyanate was added to the impregnated ferric nitrate aqueous solution, the rest were the same as in Example 1, and the prepared catalyst was recorded as C-3, and the evaluation results after 300 hours were shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com