A kind of absorption adsorption treatment method containing high concentration benzene gas

An adsorption treatment, high-concentration technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of high investment and operating costs, large equipment, and large heat release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

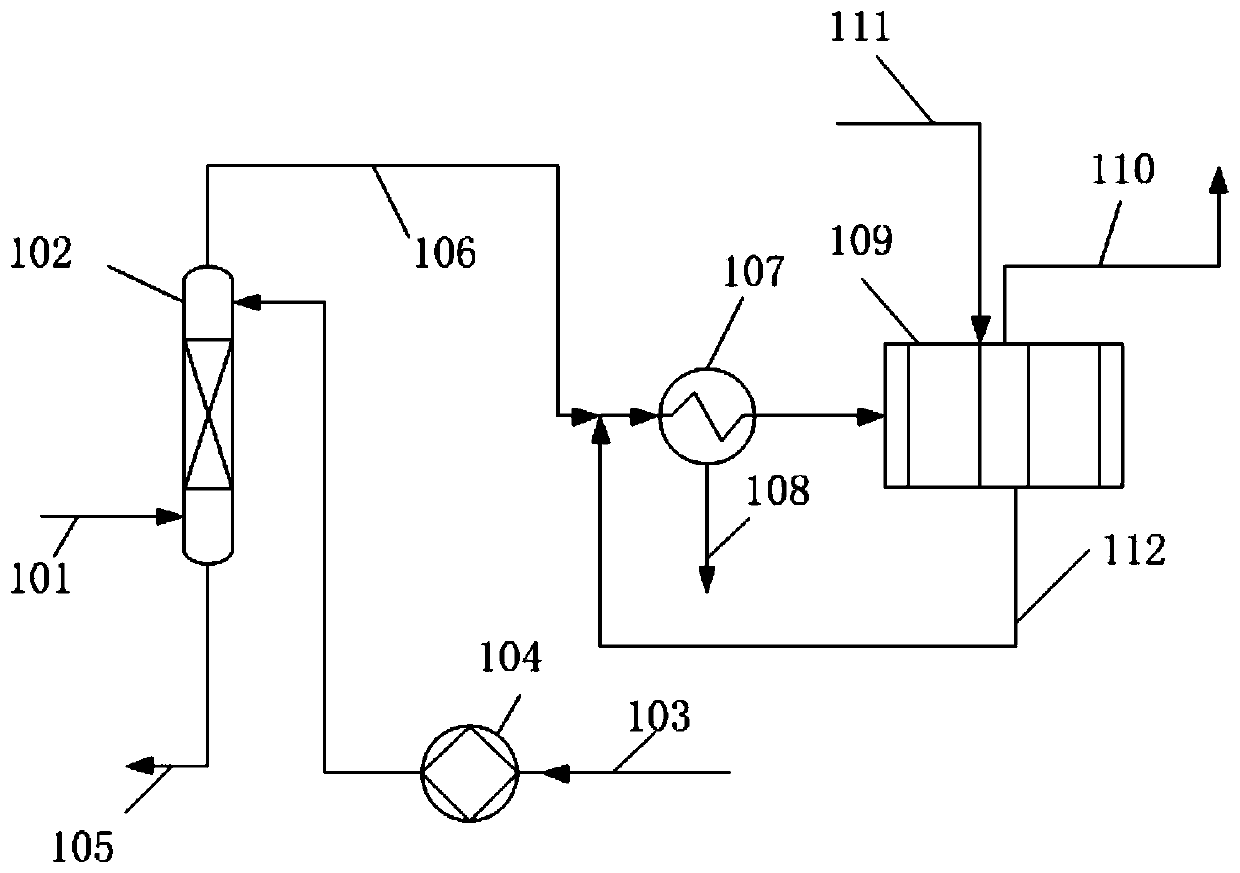

Embodiment 1

[0062] Benzene is loaded to produce benzene-containing gas, and nitrogen is used as protective gas. The main component of the generated benzene-containing gas is nitrogen, and the benzene concentration can reach up to 4 vol%. Capacity 500m 3 / h. Firstly, it is absorbed with a supergravity absorber, the absorbent is ethylbenzene, and the flow rate is 2m 3 / h, the number of theoretical plates for mass transfer in the absorber is 10. The absorbed gas enters the condenser, and the condensation temperature is as low as -10°C. Finally, enter the three boxes of activated carbon fiber adsorbers, and switch between the three boxes. A total of 120 kilograms of activated carbon fiber adsorbents are loaded. The adsorption time was 20 minutes. Water vapor desorption. After the desorbed gas is condensed by the circulating cooling water, the desorbed gas condensate enters the separator for stratification, organic matter such as ethylbenzene and benzene is recycled, and the water enter...

Embodiment 2

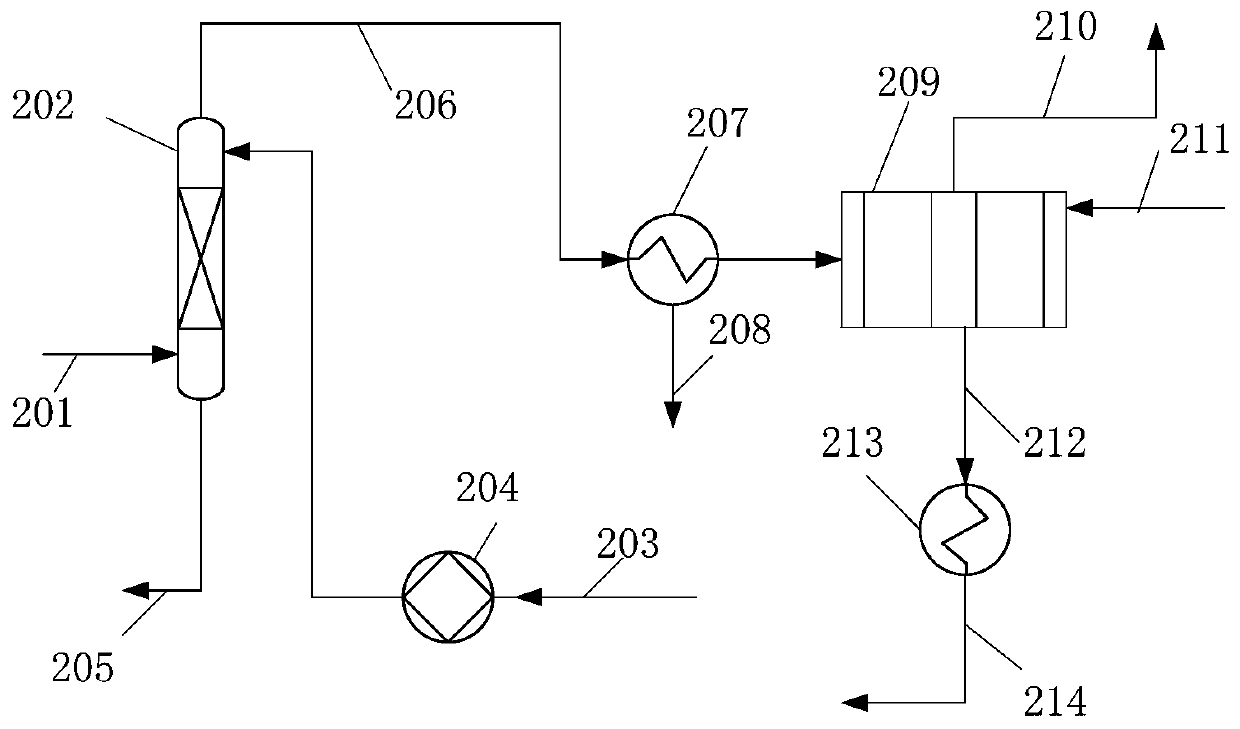

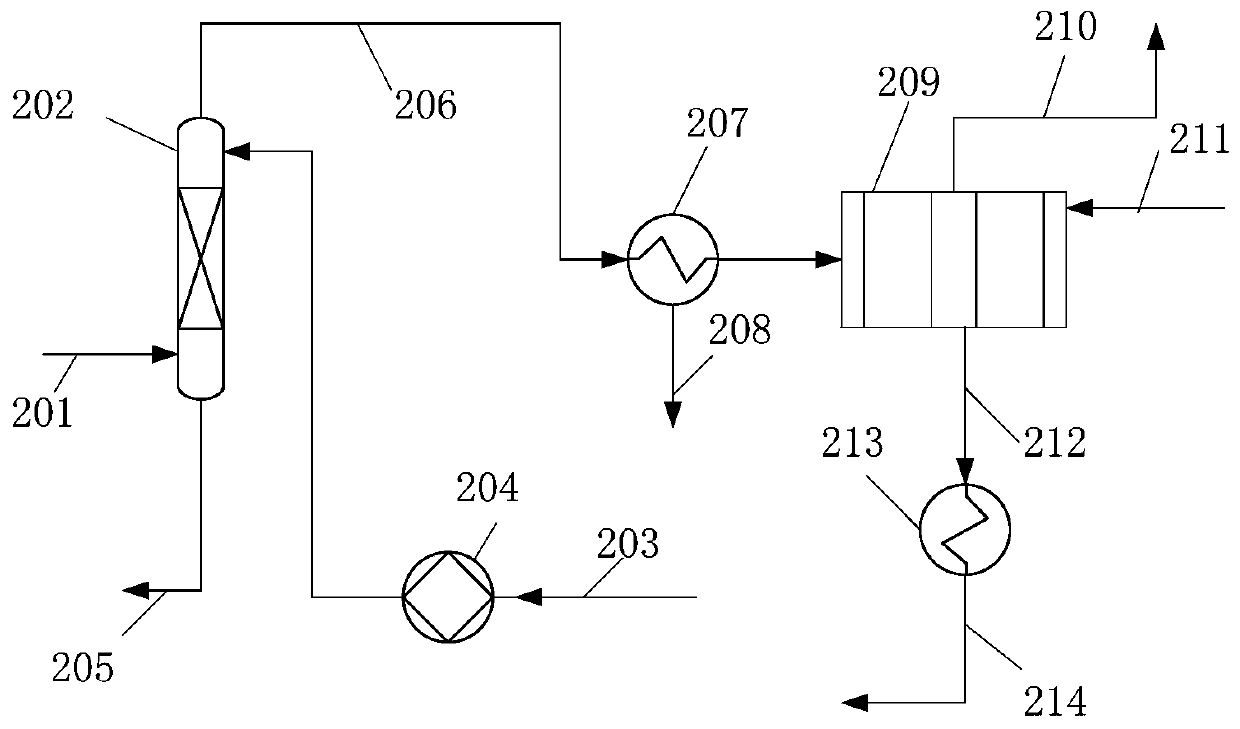

[0064] The benzene storage tank produces benzene-containing gas, and nitrogen is used as the protective gas. The main component of the generated benzene-containing gas is nitrogen, and the benzene concentration can reach up to 4 vol%. Capacity 200m 3 / h. Firstly, it is absorbed with a supergravity absorber, the absorbent is a mixture of xylene and ethylbenzene, and the flow rate is 1m 3 / h, the number of theoretical plates for mass transfer in the absorber is 10. The absorbed gas enters the condenser, and the condensation temperature is as low as -5°C. Enter three boxes of activated carbon fiber adsorbers at last, and the three boxes are switched to use, and 240 kilograms of activated carbon fiber adsorbents are filled in total. The adsorption time was 15 minutes. Hot nitrogen desorption, temperature 150°C. The desorbed gas enters the condenser inlet for processing. In the exhaust gas after absorption, condensation and adsorption treatment, the concentration of ethylben...

Embodiment 3

[0066] When benzene is unloaded, benzene-containing gas is generated, and nitrogen is used as protective gas. The main component of the generated benzene-containing gas is nitrogen, and the benzene concentration can reach up to 4.5vol%. Capacity 600m 3 / h. First, use a packed absorption tower to absorb, the absorbent is a mixture of toluene, xylene and ethylbenzene, and the flow rate is 4m 3 / h, the number of theoretical plates for mass transfer in the absorber is 10. The absorbed gas enters the condenser, and the condensation temperature is as low as -15°C. Finally, enter the three boxes of activated carbon fiber adsorbers, and switch between the three boxes. A total of 480 kg of activated carbon fiber adsorbents were loaded. The adsorption time was 10 minutes. Water vapor desorption. After the desorbed gas is condensed by the circulating cooling water, the desorbed gas condensate enters the separator for stratification, organic matter such as ethylbenzene and benzene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com