Method for preparing Nisin/chitosan/polylactic acid composite nanofiber mats by coaxial electrospinning

A technology of coaxial electrospinning and composite nanofibers, which is applied in fiber processing, filament/thread forming, textiles and papermaking, etc., can solve the problems of low efficiency and difficulty in greening the purification process, and achieve improved thermal stability, Improve antibacterial stability, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

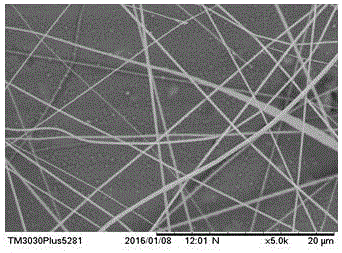

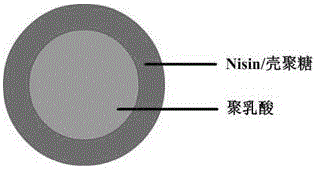

[0020] Dissolve chitosan in 90 v.% acetic acid solution and stir to dissolve to obtain a chitosan solution with a concentration of 1.5 wt.%; add Nisin and stir to obtain Nisin / Chitosan with a Nisin concentration of 1.5 wt.% Sugar solution, used as shell spinning solution for coaxial electrospinning; dissolving polylactic acid in dichloromethane to obtain a polylactic acid solution with a concentration of 10 wt.%, used as core material for coaxial electrospinning liquid; the shell spinning solution and the core spinning solution were electrospun coaxially, at a spinning voltage of 20 KV, a receiving distance of 12 cm, a flow rate of the shell spinning solution of 1.2 ml / h, and a flow rate of the core spinning solution Under the condition of 1.0 ml / h, the Nisin- / chitosan / polylactic acid composite nanofiber mat was prepared with Nisin and chitosan as the shell layer and polylactic acid as the core material. The fiber diameter was about 185 nm. The scanning electron microscope ima...

Embodiment 2

[0023] Dissolve chitosan in 70 v.% acetic acid solution and stir to dissolve to obtain a chitosan solution with a concentration of 1.2 wt.%. Add Nisin and stir to obtain Nisin / chito with a Nisin concentration of 2.4 wt.%. Sugar solution, used as shell spinning solution for coaxial electrospinning; dissolving polylactic acid in dichloromethane to obtain a polylactic acid solution with a concentration of 8 wt.%, used as core material for coaxial electrospinning liquid; the shell spinning solution and the core spinning solution were electrospun coaxially, at a spinning voltage of 8 KV, a receiving distance of 18 cm, a flow rate of the shell spinning solution of 1.5 ml / h, and a flow rate of the core spinning solution Under the condition of 1.2 ml / h, a Nisin / chitosan / polylactic acid composite nanofiber mat with Nisin and chitosan as the shell layer and polylactic acid as the core material was prepared, with a fiber diameter of about 210 nm.

[0024] Antibacterial performance test: ...

Embodiment 3

[0026]Dissolve chitosan in 80 v.% acetic acid solution and stir to dissolve to obtain a chitosan solution with a concentration of 2.0 wt.%; add Nisin and stir to obtain Nisin / chito with a Nisin concentration of 4.0 wt.% Sugar solution is used as the shell spinning solution of coaxial electrospinning; polylactic acid is dissolved in methylene chloride to obtain a concentration of 9% polylactic acid solution, which is used as the core spinning solution of coaxial electrospinning; The shell spinning solution and the core spinning solution were electrospun coaxially, at a spinning voltage of 30 KV, a receiving distance of 15 cm, a flow rate of the shell spinning solution of 0.8 ml / h, and a flow rate of the core spinning solution of 0.6 ml Nisin / chitosan / polylactic acid composite nanofiber mat with Nisin and chitosan as the shell layer and polylactic acid as the core material was prepared under the condition of / h, and the fiber diameter was about 150 nm.

[0027] Antibacterial per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com