Phase change capsule suspension/floating heat management and cold starting system

A phase change capsule and thermal management technology, which is applied in the fields of fuel cell heat exchange, fuel cell additives, fuel cells, etc. The effect of prolonging the cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Heat and melt 1000g of paraffin wax to obtain a paraffin wax solid-liquid phase change material, which is ready for use;

[0037] 2. Take 500ml of ethanol as the gas-liquid phase change material and set it aside;

[0038] 3. Using polyethylene as the material, use a film making machine to prepare a number of polyethylene film materials, the thickness of which is 120 μm, and set aside;

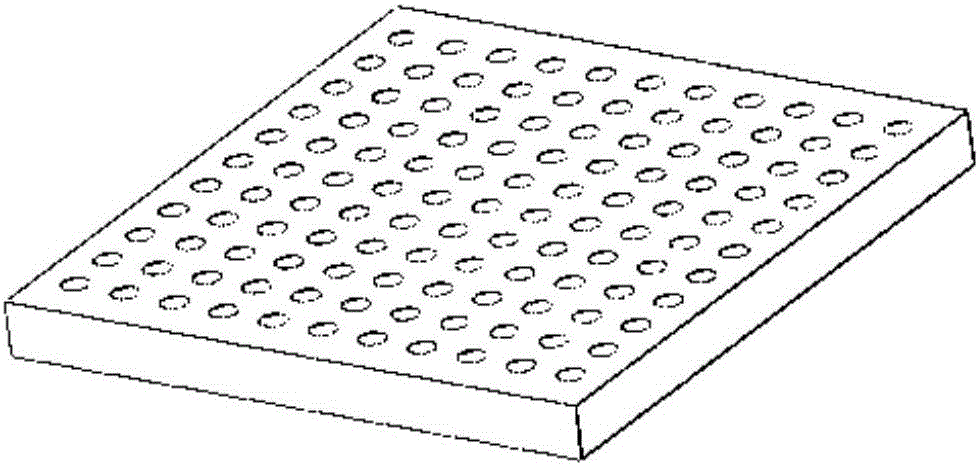

[0039] 4. Put the polyethylene film made in step 3 on the surface of the concave mold, the diameter of the hemispherical concave surface is 2.1mm, such as figure 1 shown;

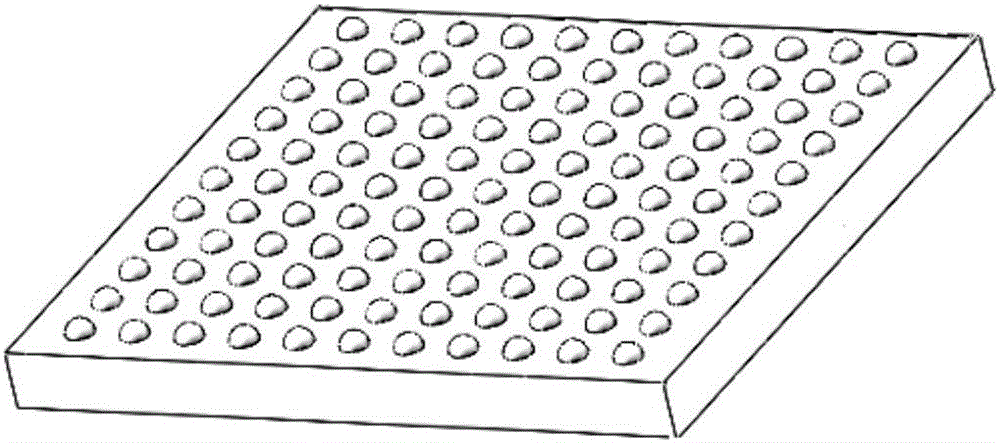

[0040] 5. Put the convex mold upside down on the surface of the concave mold with polyethylene film, the diameter of the hemispherical convex surface is 2mm, such as figure 2 As shown, the polyethylene film is pressed out of the hemispherical concave groove;

[0041] 6. Use a dispensing machine to inject the phase change materials in step 1 and step 2 into the hemispherical concave grooves obtained in step 5. A...

Embodiment 2

[0050] 1. Heat and melt 2Kg of paraffin wax to obtain a paraffin wax solid-liquid phase change material, ready to use;

[0051] 2. Take 1L of methanol as the gas-liquid phase change material and set it aside;

[0052] 3. Using polypropylene as the material, use a film making machine to prepare several polypropylene film materials, the thickness of which is 100 μm, and set aside;

[0053] 4. Place the polypropylene film made in step 3 on the surface of the concave mold, the diameter of the hemispherical concave surface is 4.1mm, such as figure 1 shown;

[0054] 5. Invert the convex mold on the surface of the concave mold with polypropylene film, the diameter of the hemispherical convex surface is 4mm, such as figure 2 As shown, the polypropylene film is pressed out of the hemispherical concave groove;

[0055] 6. Use a dispensing machine to inject the phase change materials in step 1 and step 2 one by one into the hemispherical concave groove obtained in step 5. The mass of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com