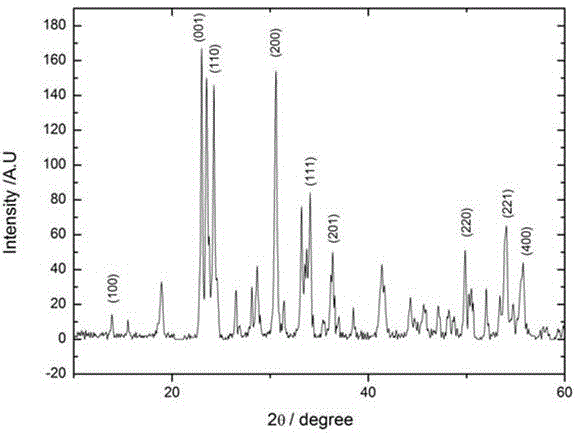

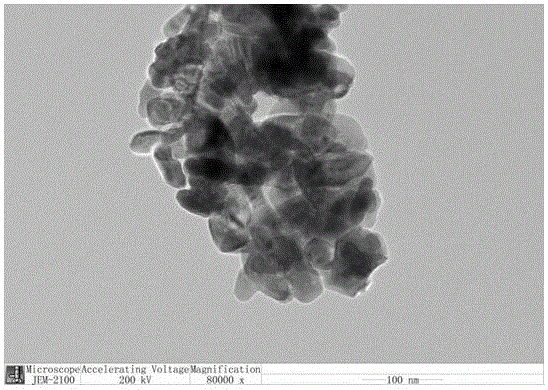

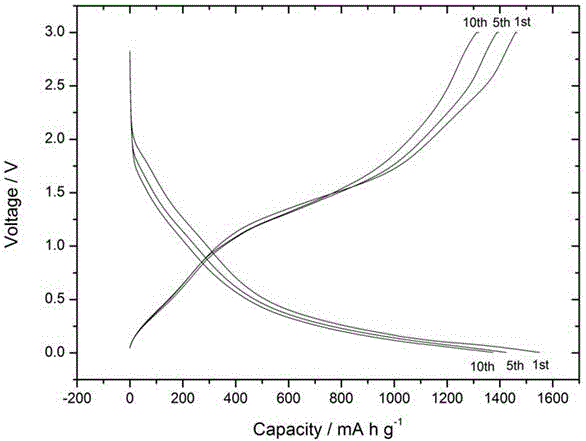

Preparation method of cobalt-doped nano tungsten oxide negative electrode material

A technology of nano-tungsten oxide and negative electrode materials, applied in the direction of tungsten oxide/tungsten hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of poor rate performance and cycle stability, small environmental toxicity, and volume change Large and other problems, to achieve the effect of improved electrochemical performance, short holding time and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of the cobalt-doped nano-tungsten oxide negative electrode material described in this embodiment specifically includes the following steps:

[0021] (1) Mix ammonium metatungstate, cobalt nitrate, and dimethylimidazole in a molar ratio of 5:1:1, then add 200mL deionized water to prepare a mixed solution, disperse and dissolve for 1h with ultrasonic vibration, and use 1mol / L The pH value was adjusted to 2 with hydrochloric acid, and the solution was transferred to a stainless steel reactor with a polytetrafluoroethylene liner, heated to 170°C and kept for 5 days, and then naturally cooled to room temperature.

[0022] (2) Pour out the mixture in the reaction kettle, filter, wash the precipitate several times with deionized water and alcohol, and dry it in a drying oven at 80°C.

[0023] (3) Place the dried powder in step (2) in an atmosphere furnace, heat it up to 500°C rapidly at a heating rate of 9°C / min in an air atmosphere, keep it warm for 90 ...

Embodiment 2

[0029] The preparation method of the cobalt-doped nano-tungsten oxide negative electrode material described in this embodiment specifically includes the following steps:

[0030] (1) Mix ammonium metatungstate, cobalt nitrate and dimethylimidazole at a molar ratio of 6:1:1, then add 200mL deionized water to prepare a mixed solution, disperse and dissolve with ultrasonic vibration for 2h, and use 1.5mol / Adjust the pH value to 1 with 1 L of hydrochloric acid, transfer the solution to a stainless steel reaction kettle with a polytetrafluoroethylene liner, put it into a drying oven for heating, keep it at 160°C for 4 days, and then cool it down to room temperature naturally.

[0031] (2) Pour out the turbid liquid in the reaction kettle, filter, wash the precipitate several times with deionized water and alcohol, and dry it in a drying oven at 80°C.

[0032] (3) Place the dried precipitate in step (2) in an atmosphere furnace, rapidly heat it up to 550°C at a heating rate of 8°C / ...

Embodiment 3

[0036] The preparation method of the cobalt-doped nano-tungsten oxide negative electrode material described in this embodiment specifically includes the following steps:

[0037] (1) Mix ammonium metatungstate, cobalt nitrate and dimethylimidazole at a molar ratio of 6:1:1, then add 200mL deionized water to prepare a mixed solution, disperse and dissolve with ultrasonic vibration for 1h, and use 2mol / L Adjust the pH value to 1 with hydrochloric acid, transfer the solution to a stainless steel reaction kettle with a polytetrafluoroethylene liner, put it in a drying oven for heating, keep it at 180°C for 6 days, cool it naturally to room temperature, and then cool it down to room temperature with the furnace.

[0038] (2) Pour out the turbid liquid in the reaction kettle, filter, wash the precipitate several times with deionized water and alcohol, and dry it in a drying oven at 80°C.

[0039] (3) Place the dried precipitate in step (2) in a microwave oven, rapidly heat it up to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum discharge specific capacity | aaaaa | aaaaa |

| Maximum discharge specific capacity | aaaaa | aaaaa |

| Maximum discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com