Active brightness enhancement film and preparation method therefor

A brightening film, active technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of strong resistance to oxygen and humidity, high thermal conductivity, and inability to meet wide color gamut at the same time. Economical cost, excellent performance, and the effect of improving the ability to resist oxygen and humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

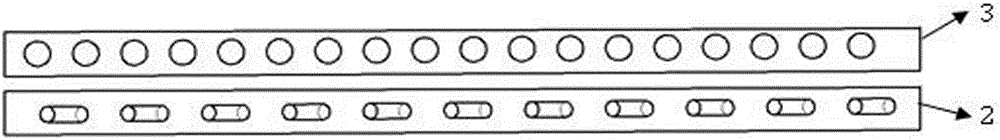

[0041] Make PVA into a solution (concentration is 10wt%), then add CdSe / CdS quantum rod material (length is 10~50nm, radius is 0.5~10nm), and mix evenly by planetary gravity mixer to make a mass fraction of 1%. The quantum rod polymer composite material is then made into a polymer film in which the quantum rods are oriented by the film-making method of electromagnetic field orientation and electrospinning.

[0042] Then prepare polymer PVC solution (concentration is 10wt%), doped with metal Au nanorods (length is 5~500nm, radius is 0.5~100nm) with mass fraction of 30%, mixed uniformly by planetary gravity mixer, and then passed electromagnetic field Orientation and electrospinning film-making methods are used to make polymer films with oriented alignment of metal nanorods.

[0043] The two layers of films are then laminated by a laminating machine to form a quantum rod active brightness enhancement film, and the quantum rods are perpendicular to the alignment direction of the ...

Embodiment 2

[0049] Make PMMA into a solution (concentration is 5wt%), then add CdTe / CdS quantum rod material (length is 10~50nm, radius is 0.5~10nm), and mix evenly by planetary gravity mixer to make a mass fraction of 1.5%. The quantum rod polymer composite material is then made into a polymer film in which the quantum rods are oriented by the film-making method of electromagnetic field orientation and electrospinning.

[0050] Then prepare polymer PVC solution (concentration is 15wt%), doped with metal Al nanorods (length is 5~500nm, radius is 0.5~100nm) with mass fraction of 60%, mixed uniformly by planetary gravity mixer, and then passed electromagnetic field Orientation and electrospinning film-making methods are used to make polymer films with oriented alignment of metal nanorods.

[0051] The two layers of films are then laminated by a laminating machine to form a quantum rod active brightness enhancement film, and the quantum rods are perpendicular to the alignment direction of th...

Embodiment 3

[0053] Add the ZnTe / CdZnS quantum wire material to the 20wt% PVP solution, mix it evenly with a planetary gravity mixer, and make a quantum wire polymer composite material with a mass fraction of 0.5%, and then make it by electromagnetic field orientation and electrospinning. A polymer film in which the quantum wires are oriented.

[0054] Add the metal Ag nanowire material to the 30wt% PMMA solution, mix it evenly through a planetary gravity mixer, and make a metal nanowire polymer composite material with a mass fraction of 30%, and then make it through the film-making method of electromagnetic field orientation and electrospinning Polymer films with aligned metal nanowires.

[0055] Two layers of quantum material polymer films and two layers of metal nanomaterial polymer films are laminated to form an active brightness enhancement film, and the quantum wires are perpendicular to the arrangement direction of the metal nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com