Semipolar surface gallium nitride based light emitting diode and preparation method thereof

A light-emitting diode and semi-polar surface technology, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of limited space for improvement and low light extraction efficiency of semi-polar surface LEDs, so as to improve crystal quality and improve current expansion , Improve the effect of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

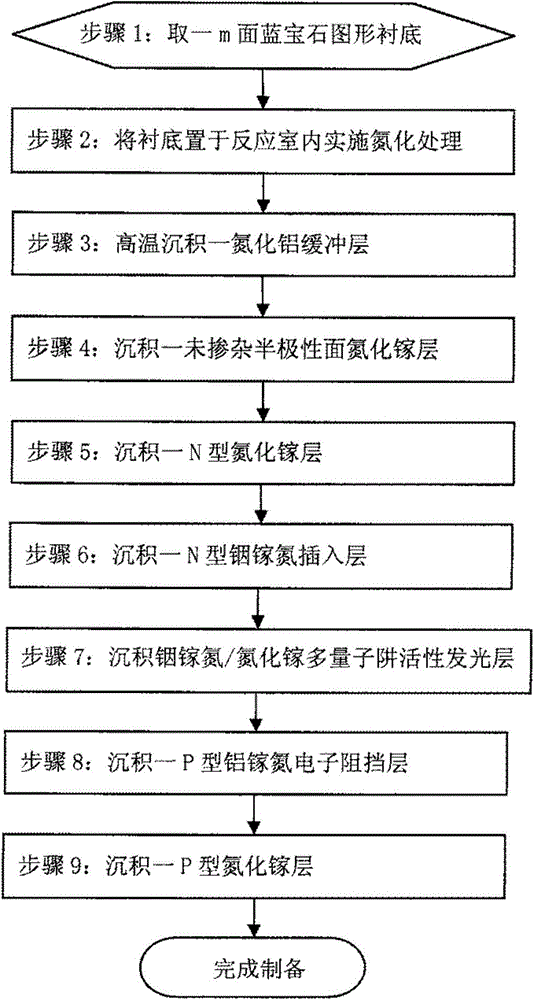

[0038]The invention prepares a semipolar (11-22) surface gallium nitride-based light-emitting diode with a special orientation. On the one hand, it effectively suppresses the internal quantum efficiency attenuation caused by the quantum-confined Stark effect in traditional devices, and on the other hand, it improves the quantum well indium The incorporation rate of the components can extend the emission wavelength of GaN-based light-emitting diodes to the dark green or even orange light region.

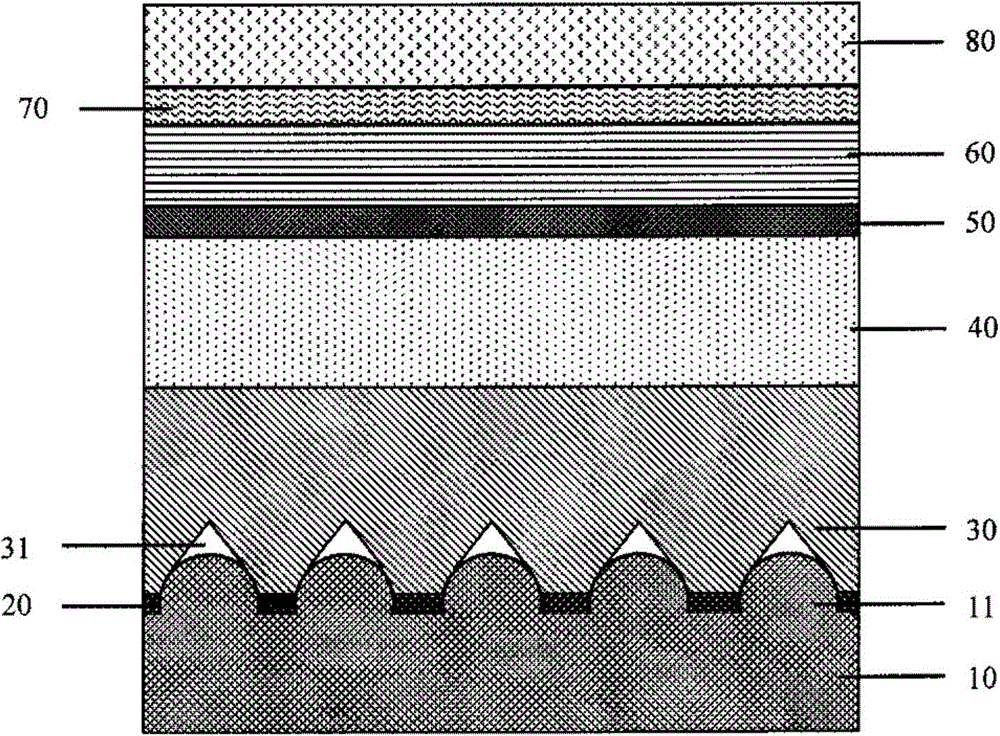

[0039] see figure 1 As shown, the present invention provides a semi-polar gallium nitride-based light-emitting diode, including:

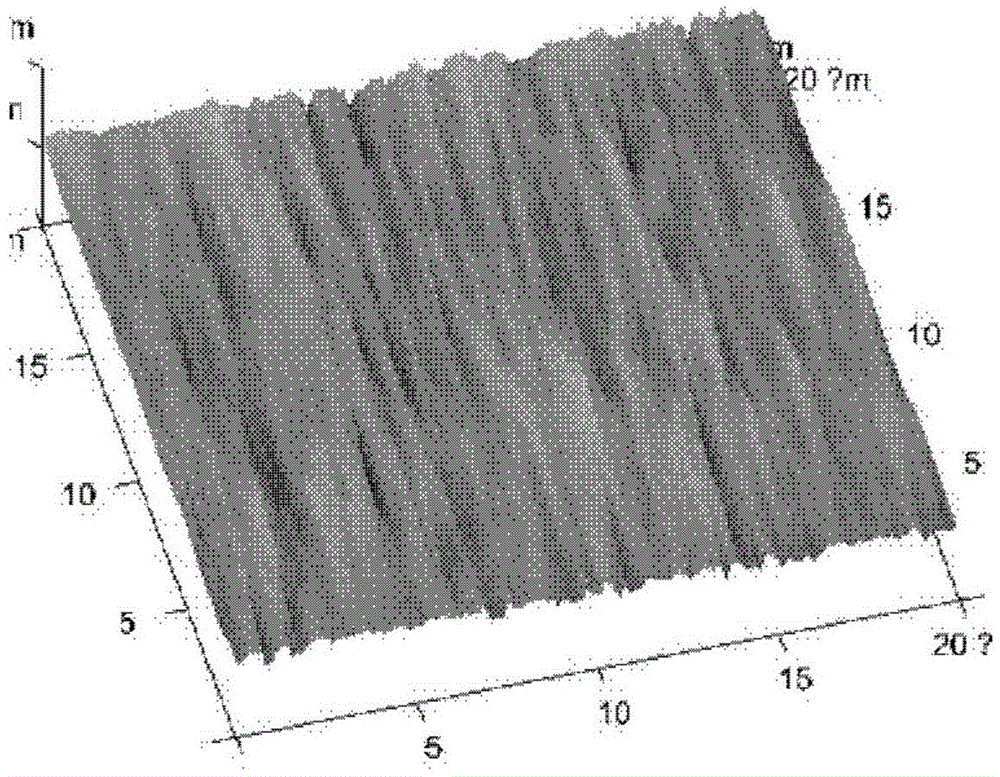

[0040] A substrate 10, the surface of which has raised patterns 11 arranged periodically. The substrate 10 is a sapphire substrate with an orientation (10-10) m plane, and the period of the raised patterns 11 on its surface is 3-7 μm, and the diameter of the bottom is It is 2-4 μm, the height is 1-2 μm, and the interval between each raised pattern 11 is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com