Production method for chassis with sterilization function

A production method and chassis technology, applied in the direction of instruments, electrical digital data processing, digital data processing components, etc., can solve the problems of insufficient utilization of output line functions and breeding of bacteria, so as to avoid the decline of heat dissipation and dust reduction , good bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

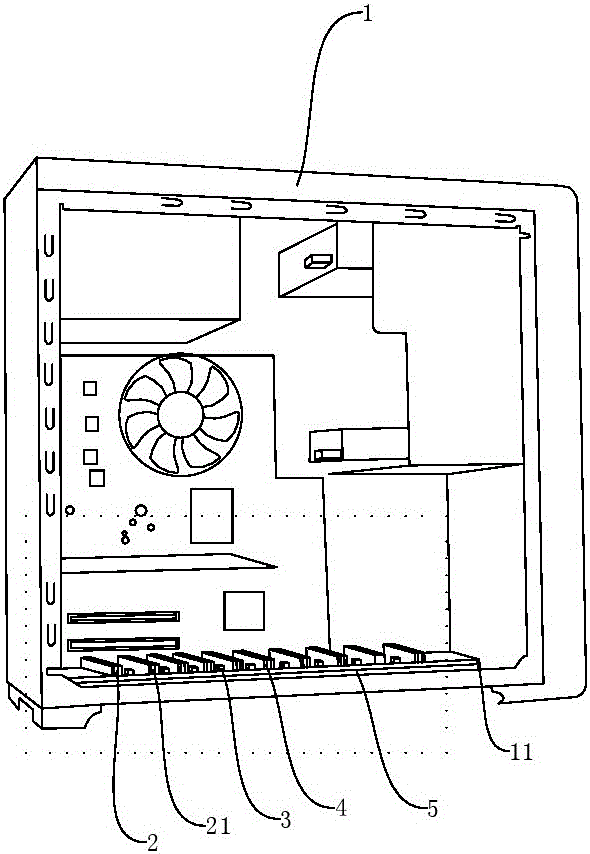

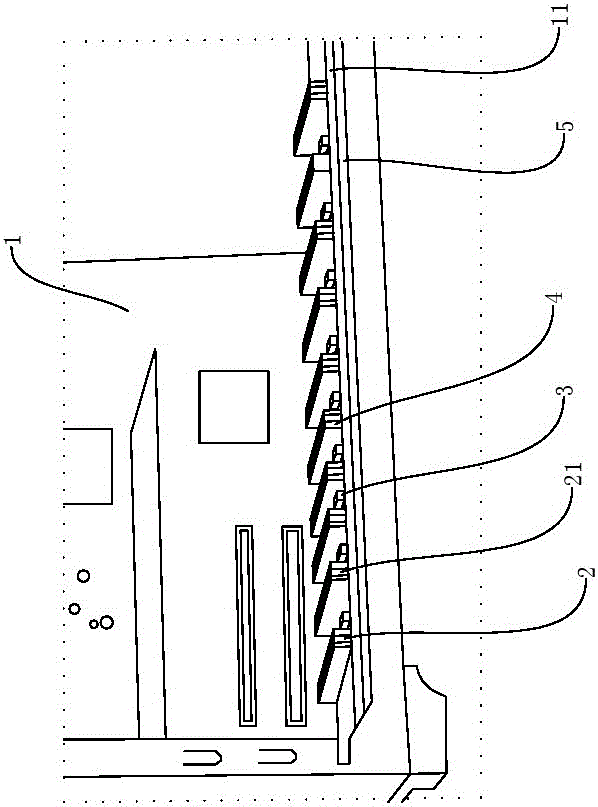

[0026] Basic as attached figure 1 , figure 2 Shown: the manufacture method of the cabinet with sterilizing function in this embodiment,

[0027] (1) Chassis modification steps: Lay a good insulating bottom layer on the bottom plate of the chassis, embed magnets in the bottom layer, and then glue the bottom layer on the bottom plate of the chassis. The main component of the insulating bottom layer is polyvinyl acetate;

[0028] (2) Manufacturing steps of the mounting plate 11: on the mounting plate 11, use a groove cutter to open parallel grooves, the depth of the grooves is 2-5mm, and select a smooth plate-shaped conductor as the positive plate 2 and the negative plate 21, The number of the positive plate 2 and the negative plate 21 is 5 pieces, and the positive plate 2 and the negative plate 21 are embedded in the groove at intervals, and finally the positive plate 2 is connected in parallel with a wire, and connected to the positive pole of the output end of the power supp...

Embodiment 2

[0031] Compared with Example 1, the difference is that the preparation method of the insulating bottom layer is to add natural rose essence and alcohol to polyvinyl acetate, then press it into a round cake, and then stick it on the On the ventilation pipe, the insulation bottom layer 5 is inflated by the air blowing of the ventilation pipe, and then it is punctured after it is of an appropriate size, and the insulation bottom layer 5 is just covered on the mounting plate 11 surface. The insulating bottom layer 5 is very thin, which can save the space inside the cabinet.

Embodiment 3

[0033] Compared with Example 2, the difference lies in that in the manufacturing step of the mounting plate 11 , the sponge layer 4 is wrapped on the surfaces of all the positive plates 2 and the negative plates 21 . The sponge layer 4 is loose and porous, and has a strong dedusting effect on dust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com