Separation and recovery of aluminum electrolytic cell lining solid waste and electric resistance furnace for desulfurization of petroleum coke

A technology for aluminum electrolytic cells and solid waste, which is applied in the fields of metallurgy and the environment. It can solve the problems of high and low temperature of the conductive current resistance heating element, the cross section should not be too large, and uneven distribution of heating current, so as to achieve uniform axial current distribution, The effect of improving production efficiency and separation effect and expanding the loading capacity of a single furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

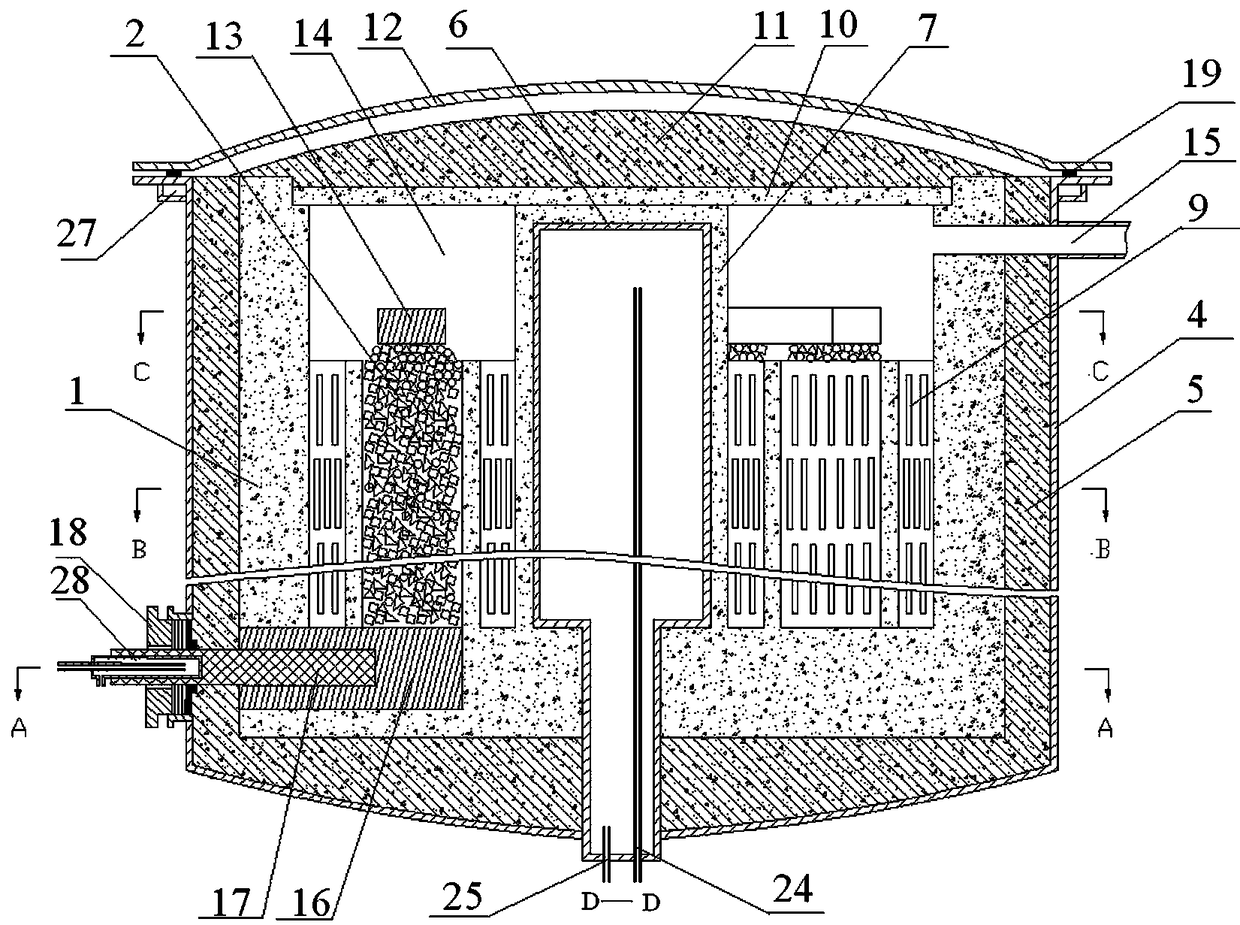

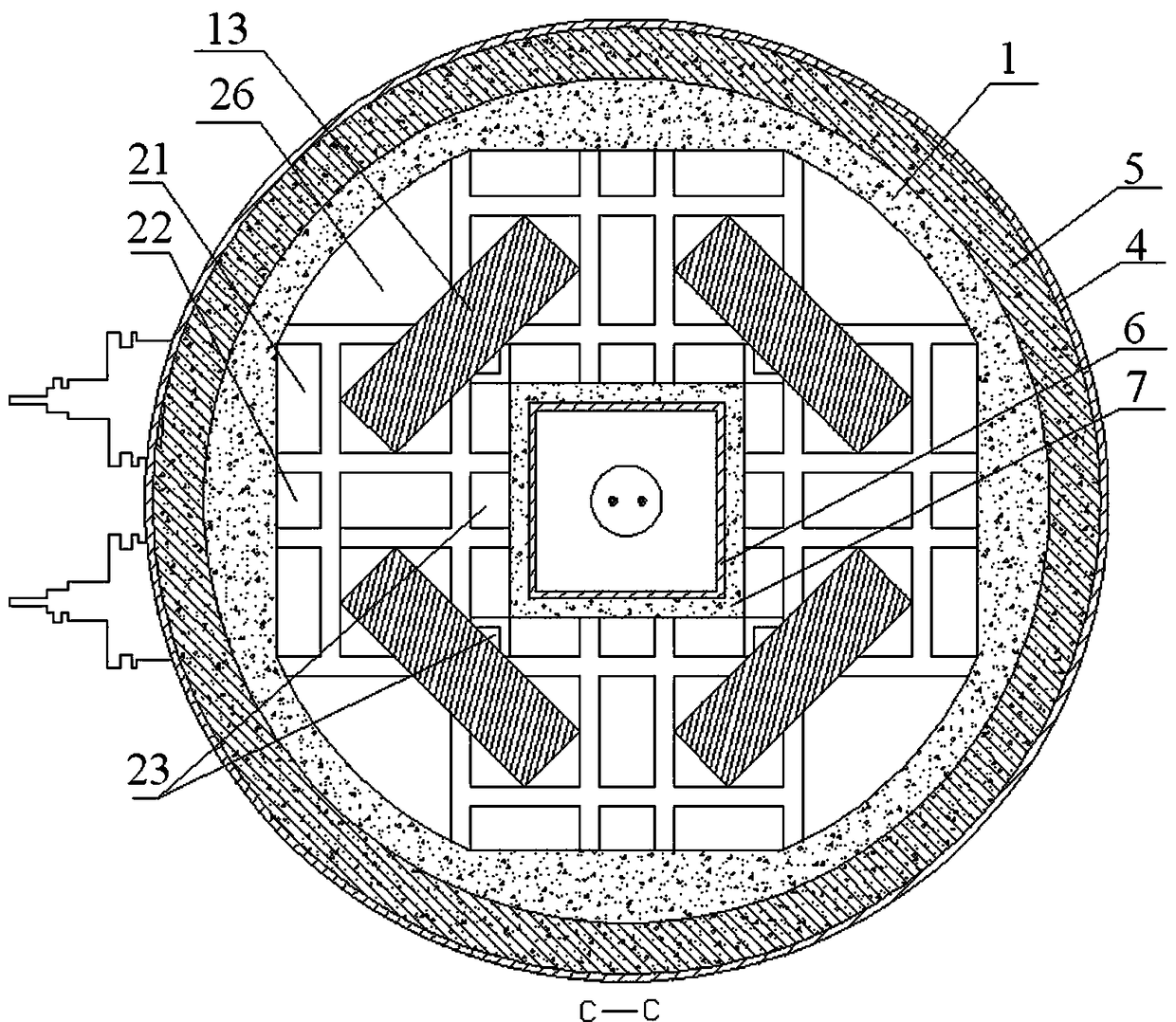

[0074] The structure of electric resistance furnace for separation and recovery of aluminum electrolytic cell lining solid waste and petroleum coke desulfurization is as follows: figure 1 As shown, the A-A surface structure is shown as figure 2 As shown, the B-B surface structure is as image 3 As shown, the C-C surface structure is as Figure 4As shown; including furnace shell (4), spherical crown furnace cover (12), furnace lining (5), barrel refractory concrete masonry (1), refractory concrete roof (10), insulation cover (11) and two a graphite electrode (16); the furnace shell (4) and the spherical crown furnace cover (12) are made of steel plates, the top of the furnace shell (4) is provided with a cooling water jacket (27), and the top of the furnace shell (4) is connected to the ball Vacuum gaskets (19) are set between the crowned furnace covers (12) for sealed connection; the inner wall of the furnace shell (4) is connected to the furnace lining (5), and the furnace...

Embodiment 2

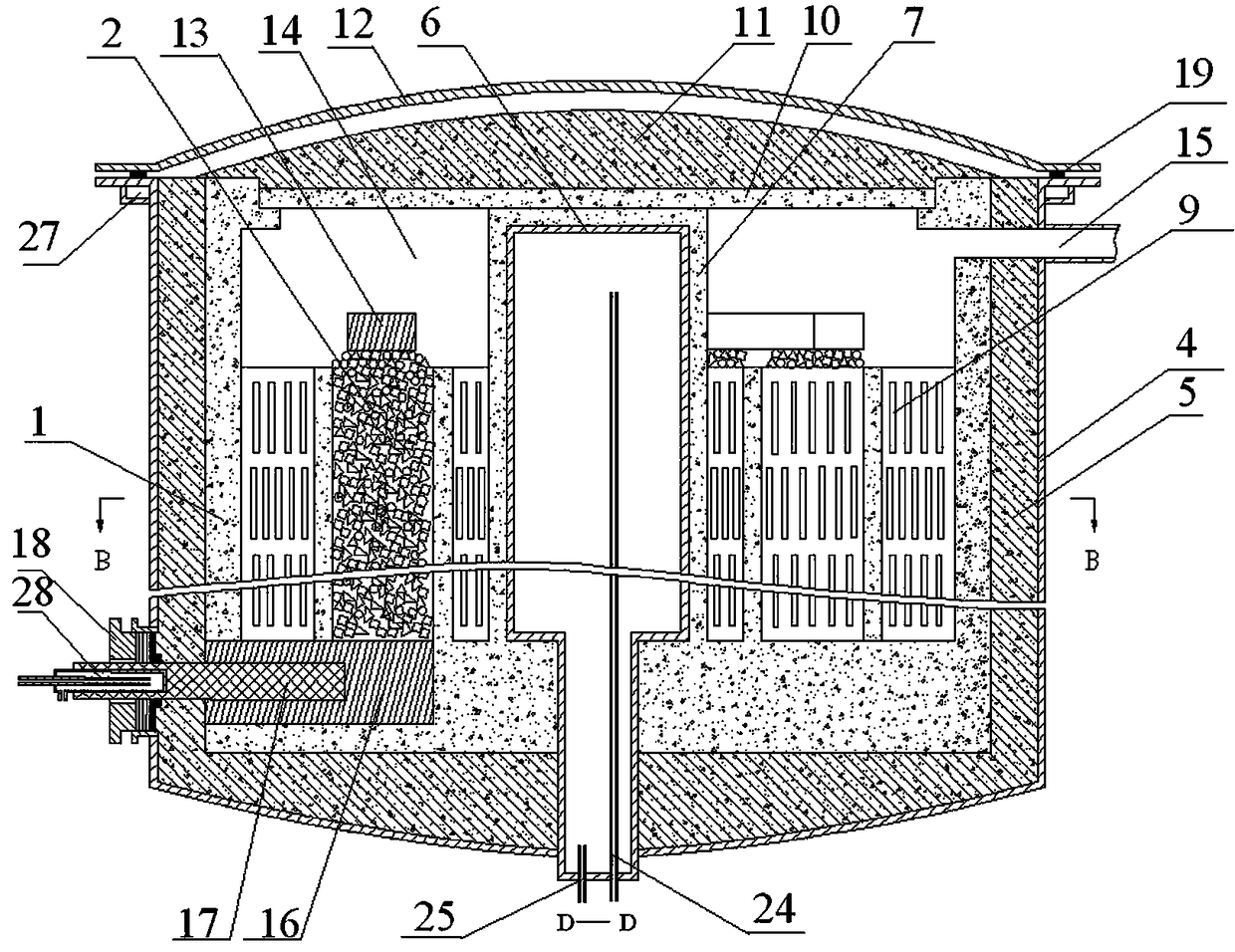

[0081] The structure of electric resistance furnace for separation and recovery of aluminum electrolytic cell lining solid waste and petroleum coke desulfurization is as follows: Figure 5 As shown, the B-B surface structure is as Image 6 Shown, structure is the same as embodiment 1, difference is:

[0082] Barrel-type refractory concrete masonry (1) The outer wall and inner wall are both barrel-shaped, and the horizontal section of the external well-type auxiliary material room formed between the well-type main material room and the barrel-type refractory concrete masonry is non-rectangular.

Embodiment 3

[0084] The structure of electric resistance furnace for separation and recovery of aluminum electrolytic cell lining solid waste and petroleum coke desulfurization is as follows: Figure 7 As shown, the A-A surface structure is shown as Figure 8 As shown, the B-B surface structure is as Figure 9 As shown, the C-C surface structure is as Figure 10 Shown; Structure is the same as embodiment 1, and difference is:

[0085] Barrel-type refractory concrete masonry (1) The horizontal cross-sections of the outer wall and inner wall are polygonal, and the horizontal cross-sections of each well-type main material room and each well-type auxiliary material room are square or rectangular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com